in modern industrial manufacturing,Injection molding is an efficient、Precise molding process,is playing an increasingly important role。This article will delve into the importance of injection molding,Analyze its core value in industrial production,and bring you some inspiring thoughts。By reading this article,You will gain a better understanding of the injection molding process,and how it shapes our industrial future。

one、Injection molding process overview

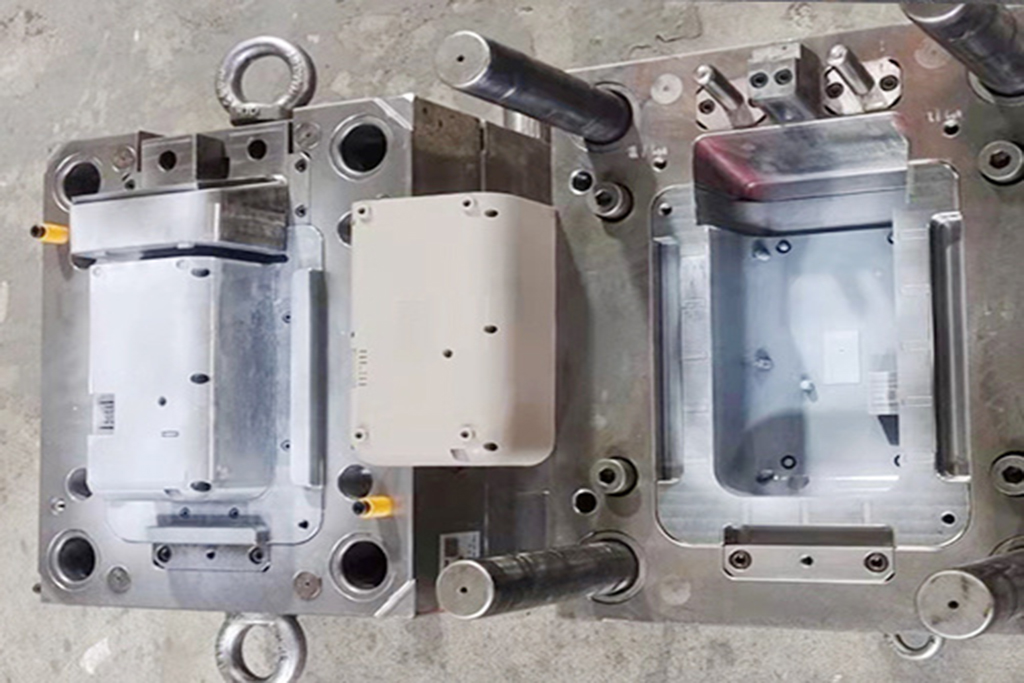

Injection molding,Injecting molten plastic into the mold,After cooling and solidification, plastic products of the desired shape and size are obtained.。This process has high production efficiency、low cost、High product precision、Advantages such as strong replicability,widely used in automobiles、electronic、medical、toys and other fields。

two、Analysis of the importance of injection molding

Improve production efficiency:Injection molding processUse automated production lines,able to achieve continuous、efficient production。Compared with traditional manual or semi-automatic production methods,Injection molding process greatly improves production efficiency,Reduced production costs。

Ensure product accuracy:Injection molds with high precision and stability,Able to ensure accurate size of plastic products produced、consistent shape。This is critical for products that require a precise fit or high appearance requirements。

Promote product diversification:The injection molding process can be adapted to the production of plastic products with various complex shapes and structures.。By designing different molds,Product diversification can be easily achieved,Meet market demand。

Promote environmental development:The injection molding process is also of great value in plastic recycling and reuse。Injection molding processing by recycling waste plastic products,Enables recycling of resources,Reduce environmental pollution。

three、Inspiring Thoughts on Injection Molding

The importance of the injection molding process is not only reflected in its production efficiency and product accuracy,What's more, it provides us with an efficient、Environmentally friendly manufacturing methods。In today's pursuit of sustainable development,We should pay more attention to the innovation and optimization of injection molding processes,to improve resource utilization efficiency,Reduce environmental pollution。at the same time,The injection molding process also provides more possibilities for our product design,Encourage us to continue to challenge tradition,Innovative design。

Four、The future of injection molding

With the advancement of science and technology and the improvement of environmental awareness,,Injection molding technology will usher in broader development prospects。future,The injection molding process will pay more attention to the environmental protection of materials、Intelligentization of molds and automation of production processes。Through integration with other advanced technologies,such as artificial intelligence、Internet of Things, etc.,Injection molding process will become more intelligent、Efficient production process,Inject new vitality into industrial manufacturing。

five、Conclusion

Injection molding process is an important part of modern industrial manufacturing,Its importance is self-evident。By continuously improving production efficiency、Ensure product accuracy、Promote product diversification and promote environmental development,Injection molding technology is making an important contribution to shaping the future of industry。