In today's broad arena of manufacturing,The injection molding process is characterized by its unique applicability and efficiency,Become a product shaper、An important force in promoting industry innovation。This article will delve into the applicability of injection molding,Reveal its wide range of applications and far-reaching influence in many fields,at the same time,Combined with AI technology,Show you the future development trend of injection molding technology。

one、Injection molding process overview

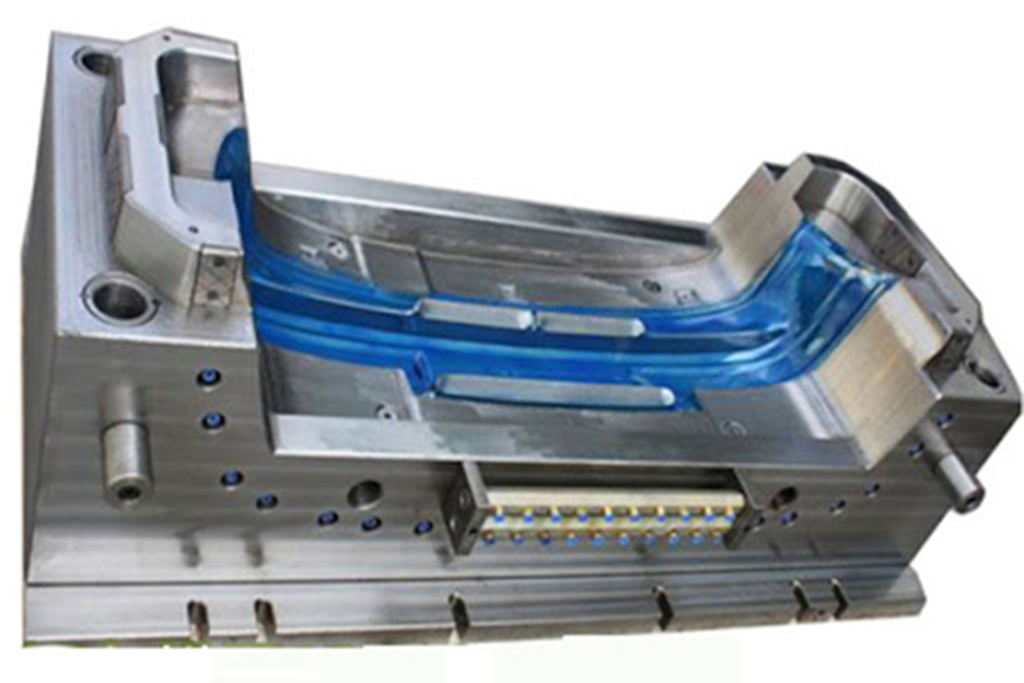

Injection molding,As a method of injecting molten plastic into a mold,Manufacturing process to form products after cooling and solidification,Since its birth, it has been characterized by its high precision、High efficiency、Low cost features,Favored by the manufacturing industry。From daily necessities to high-tech products,Injection molding is everywhere,Brings convenience and beauty to our lives。

two、Exploring the application of injection molding

automobile manufacturing:in the automotive industry,Injection molded parts are widely used in interior and exterior decoration of car bodies、engine parts、Chassis system, etc.,Not only reduces the weight of the car body,Improved fuel efficiency,Also enhances vehicle safety and comfort。

Electronic products:Smartphone、Tablet、In electronic products such as laptops,Injection molded part as housing、Bracket、Key components such as buttons,Ensure the beauty and durability of the product。

medical device:in medical field,Injection molding process is used to manufacture syringes、test tube、Catheters and other disposable medical supplies,and surgical instruments、Rehabilitation equipment, etc.,Guaranteed medical safety and quality。

Household items:From kitchen items to furniture accessories,Injection molded parts with their various colors、shape and material,Meet people's personalized needs for home life。

three、Injection molding technology innovation and AI integration

With the rapid development of AI technology,Injection molding process is ushering in a new round of technological revolution。AI in mold design、Production optimization、Applications in quality control, etc.,Make the injection molding process more intelligent、Efficiency。Through big data analysis,AI can accurately predict various variables in the injection molding process,Optimize production parameters,Reduce scrap rate,Improve production efficiency。

Four、The future of injection molding

Looking to the future,Injection molding will continue to play an important role in manufacturing。With the advancement of material science and the increasing awareness of environmental protection,Bio-based plastics、New materials such as degradable plastics will gradually be used in injection molding processes,Promote manufacturing to go green、sustainable development。at the same time,The deep integration of AI technology will further enhance the intelligence level of injection molding process,Achieve more precision、efficient production。