Extremely fast innovation

Excellent and efficient

unique charm

ISO14001-2015 certified manufacturer,Able to ensure the provision of the highest quality products in an industry that requires a high degree of environmental protection and quality control。

As an electronic product manufacturing workshop and innovative technology expert,We offer a range of manufacturing technologies and services,From precision electronics assembly to laser cutting。

We have been producing electronic technology products for more than ten years,Our expert engineers know how to get the best results from your design。

We can handle orders of almost any size,From single electronic product prototypes to full-scale production of smart devices at scale。

Our state-of-the-art facilities and extensive partner network enable us to fulfill orders quickly,No matter the order quantity or complexity。

Our engineers will quickly review your design,Provide fast and accurate quotes for projects。

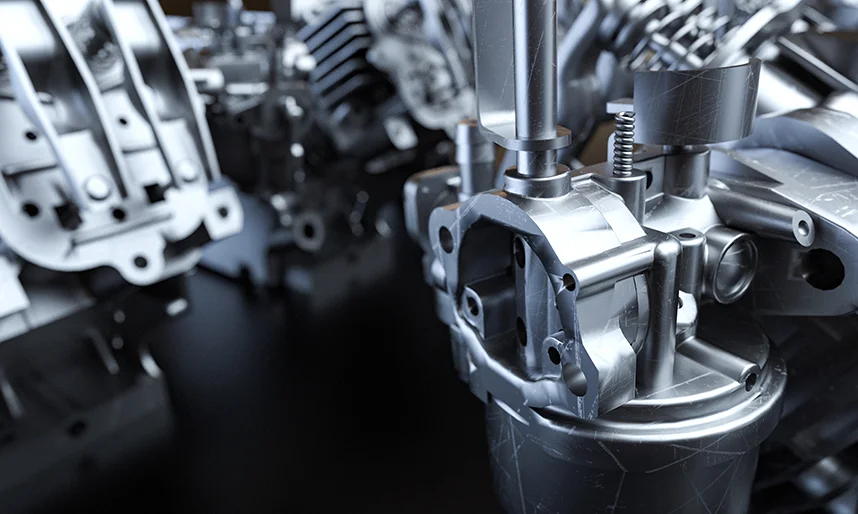

By using CNC numerical control processing technology,We can create prototypes and production parts in a variety of complex shapes。

We provide small batch test molds and high-volume production molds。

We provide 4D printing services for specialty material parts using a range of advanced additive manufacturing technologies。

The manufacturing industry is increasingly adopting industrial intelligence to improve production efficiency.,This is one of the key factors driving the increased demand for prototypes and parts in the industrial machinery industry。

With the advancement of mining intelligence,,Alloy components are increasingly used in industry,Industrial machinery prototypes and parts are also increasingly critical。

We undertake custom orders to meet our customers’ production needs。Generally speaking,Some of these machines have more modest output。This avoids the situation of overstocking due to technology updates。

Industrial equipment part display

over the years,We continue to accumulate relevant experience,Give us the ability to undertake any industrial equipment production tasks。Below is a collection of pictures of industrial equipment samples and production components we build for customers around the world

A wide range of materials are available for all our manufacturing processes。Listed below are some common choices for industrial equipment projects。

Available in a variety of high level surface treatments。We list just some of the common surface treatment options。More surface treatment options for custom parts for the industrial equipment industry。

Yes,Rapidefficient Manufacturing is an ISO9001-2015 certified manufacturer。No matter what kind of project or every customer,We all manufacture parts to high standards。

For some manufacturing processes (such as die-casting),We can provide initial samples of your parts,Then provide subsequent samples according to demand。

We can fulfill orders quickly,But the delivery time depends on some factors,such as manufacturing processes、Order quantity and part complexity。The fastest way to CNC machine parts is 4 sky,3The fastest way to 3D print parts is just 2 sky,The mold manufactured through rapid tooling is the fastest and only needs 4-6 sky。

Rapidefficient manufacturing takes privacy and security seriously,and will happily sign a non-disclosure agreement (NDA) upon your request,Let you feel confident about your intellectual property rights。