In the vast starry sky of modern manufacturing industry,Injection molds are like bright stars,Its unique light illuminates every aspect of product molding。This article will delve into the importance of injection molds、Applicability and the innovative impact of AI technology on it,aims to present readers with a comprehensive、An in-depth look at the world of injection molds。

one、Injection mold:Precision cornerstone of industrial manufacturing

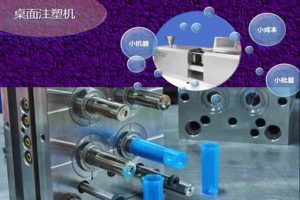

Injection mold,As a core component of the injection molding process,Responsible for injecting molten plastic into a predetermined shape mold cavity,The important task of forming the product after cooling and solidification。Its design accuracy、Material selection and manufacturing process directly determine the quality and performance of the final product。Injection molds are not only widely used in automobiles、electronic、medical、toys and other fields,It is also a key driving force in promoting the development of manufacturing industry to a higher level.。

two、Application exploration of injection molds

High precision manufacturing:Injection molds enable manufacturing with micron-level precision,Ensure product dimensional accuracy and consistency,Meet the demand for high-precision products。

Complex shape forming:Through precise mold design,Injection molds can mold products of various complex shapes,Provides designers with unlimited creative space。

Efficient production:Injection mold with automated production line,able to achieve high efficiency、continuous production,Greatly improved production efficiency,Reduced production costs。

Material diversity:Injection molds are suitable for molding a variety of plastic materials,Includes thermoplastics、Thermosetting plastics, etc.,Provides a wealth of material choices for products。

three、AI technology:The innovative power of injection molds

With the rapid development of AI technology,The injection mold industry is ushering in a technological revolution。AI in mold design、Production optimization、Applications in quality control, etc.,Are profoundly changing the production methods and efficiency of injection molds。

Smart design:AI can be based on big data analysis,Quickly generate mold design solutions,Improve design efficiency and accuracy。

Production optimization:Through AI algorithm,Can monitor various parameters in the production process in real time,Optimize production process,Reduce scrap rate,Improve production efficiency。

Quality control:AI can accurately predict mold wear、Potential problems such as deformation,Take steps in advance,Ensure product quality is stable and reliable。

Four、The future of injection molding

Looking to the future,The injection mold industry will continue to maintain rapid development momentum。With the advancement of material science and the popularization of intelligent manufacturing technology,Injection molds will move towards higher precision、more complex shapes、The direction of more efficient production。at the same time,The increase in environmental awareness will also prompt the injection mold industry to move towards green、sustainable development。

five、Conclusion

Injection molds are an important part of modern manufacturing industry,Its importance is self-evident。Through continuous technological innovation and optimization,Injection molds are contributing important forces to the prosperity and development of the manufacturing industry。