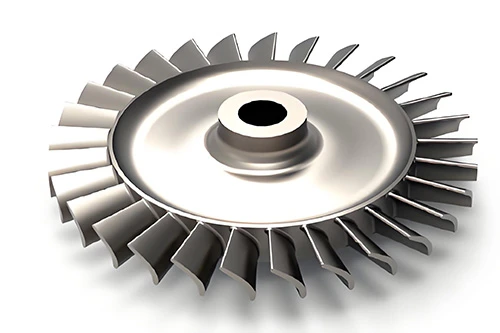

Impresión 3D de metal

Atender

Impresión 3D de metal, That is, the application of additive manufacturing technology in the field of metal materials, is an advanced manufacturing method that creates complex parts by stacking metal materials layer by layer.

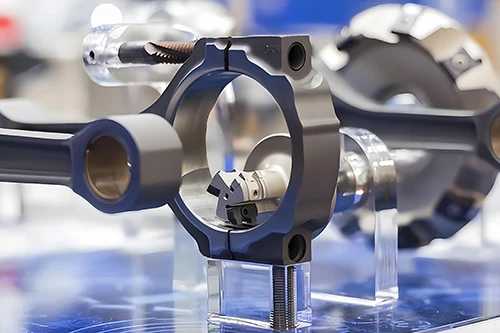

Prototipo de mecanizado CNC único

Strong manufacturing capabilities for complex structures

High precision and performance

Personalized customization and quick response

Our metal 3D printing capabilities

There are many reasons to choose Rapidefficient metal 3D printing. Primero, high degree of design freedom, Can break through the limitations of traditional manufacturing, print out complex, fine structure, Providing possibilities for innovative design. Second, it is fast and efficient, Products can be manufactured in a short time, Greatly shorten the development cycle and delivery time, Meet market demand for rapid product updates. Third, the advantages of customization are obvious, Can be customized according to the specific needs of customers, Applications to meet different scenarios. Fourth, high material utilization rate, By precisely controlling the use of materials, Reduce waste, Reduce costs. Fifth, the accuracy is higher, Can print high-quality metal parts, Good performance. These features make Rapidefficient metal 3D printing useful in aerospace, médico, It has broad application prospects in many fields such as automobiles.

Metal 3D printing is an additive manufacturing technology, Build 3D objects by adding metallic materials layer by layer.

Its working principle is usually to use high-energy heat sources (such as lasers, Electron beam, etc.) selectively melt or sinter metal powder or wire according to a pre-designed three-dimensional model, Stacked layer by layer, Finally get the metal parts you need.

Aerospace parts manufacturing

Aerospace parts with complex internal structures and special-shaped surfaces can be manufactured, like engine blades, Wing structural parts, etc., Reduce weight while maintaining strength, Improve aircraft performance, And can quickly produce prototypes, Shorten R&D cycle.

Medical implant and device manufacturing

Ability to customize and produce personalized implants based on patient’s specific conditions, such as artificial joints, Spinal immobilizer, etc., Good fit with patient’s body; Precision medical equipment can also be manufactured, such as surgical instruments, Micro medical equipment, etc., Provide better support for medical operations.

Auto parts manufacturing

Can produce high-performance automotive parts, such as engine block, Piston etc., Improve vehicle power performance and reliability; It can also meet the needs of personalized car customization, Manufacture of exterior decorative parts, Personalized parts such as interior parts.

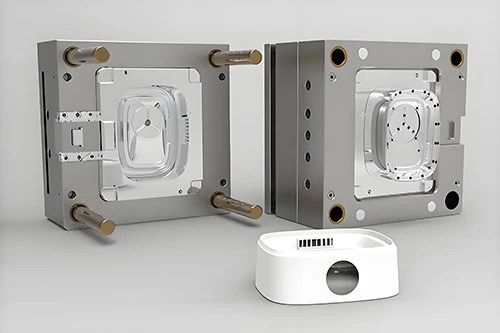

Mold making

Ability to manufacture molds with conformal cooling water channels, Improve cooling efficiency, Reduce cooling time for injection molding or die casting, Improve production efficiency and product quality; Complex mold structures can also be easily produced, If there is a deep cavity, thin wall, Molds with undercut and other structures, Reduce manufacturing difficulty and cost.

Energy sector parts manufacturing

in the oil and gas industry, Can be manufactured to resist corrosion, High temperature resistance, High pressure resistant parts, like a drill bit, válvula, Pipe connectors, etc.; In the field of new energy, Efficient solar panel supports can be made, Wind turbine blades and other parts, Meeting the special needs of the energy sector.

Art design and cultural creative products

Artists and designers can use the technology to turn ideas into physical works, Create complex shapes, Uniquely structured art sculpture, Decoraciones, etc.; It can also be used for restoration and reproduction of cultural relics, Making replicas of cultural relics or repairing damaged parts of cultural relics, Convenient for research and presentation.

Stunning display of metal 3D printed parts. There are complex aerospace components here, such as lightweight engine blades; Precisely customized medical implants, such as artificial joints. They demonstrate high precision and performance. The surface of the parts is delicate, Rich in details, Reflecting the charm of advanced manufacturing technology. These parts are not only technological achievements, It is also a symbol of innovation and breakthrough, Brings new development opportunities to many fields.

Ability to print complex shapes that are difficult to achieve with traditional processes, Such as internal hollow structure, etc., Improve product performance and design freedom.

Manufactured to specific needs, No need to open a mold, Suitable for small batch production, Satisfacer las necesidades personalizadas de diferentes clientes.

Rapidly manufacture prototypes and products, Reduce process, Dramatically shorten R&D and production time, Improve efficiency.

Etapa de diseño

1. Design the required metal part model using professional 3D modeling software. Make sure the model is well structured, Dimensions are accurate, Also consider the process characteristics of metal 3D printing, Such as avoiding too small structures, Reasonable design support, etc..

2. Optimize the model, to improve printing success rate and part performance. Por ejemplo, Reduce unnecessary complex features, Optimize wall thickness, etc..

Selección de material

1. Select the appropriate metal material according to the use and performance requirements of the part. Common metal 3D printing materials include titanium alloy, Stainless steel, Aleación de aluminio, etc..

2. Understand the properties of your chosen material, Such as melting point, thermal expansion coefficient, Mechanical properties, etc., In order to set appropriate parameters during the printing process.

Preparing for printing

1. Import the designed model file into the metal 3D printer software, Perform slicing. Slicing software will divide the model into several layers, And generate a command file that can be recognized by the printer.

2. Set printing parameters, Including printing layer thickness, Laser power, Scan speed, Temperature etc., These parameters affect print quality and efficiency, Need to be adjusted according to material and part requirements.

Printing process

1. Check the status of your metal 3D printer, Ensure equipment is functioning properly. Includes inspection of powder supply system, laser system, Movement system, etc..

2. Start the printer, Start printing. During printing, Closely observe the operation of the printer, Pay attention to whether there are any abnormalities, such as powder clogging, Laser failure, etc., if something goes wrong, Stop printing in time and process it.

Postprocesamiento

1. After printing is completed, Remove the part from the build platform. Remove support structures from parts, Methods such as mechanical processing or chemical etching can be used.

2. Post-process parts, Such as heat treatment, Tratamiento superficial, etc., to improve part performance and surface quality. Por ejemplo, Annealing can eliminate the internal stress generated during the printing process, Polishing improves the surface finish of the part.

Si necesita un pequeño número de piezas o 10000 Múltiples objetos de producción que finalmente se usan, CNC Machining es un método de fabricación ideal. Los siguientes son los servicios CNC personalizados que lanzamos.

Por efecto rápido, Puede completar la fabricación de productos en poco tiempo, para poder ingresar rápidamente al mercado.

La fabricación de moho eficiente es una forma rentable, Capaz de cerrar la brecha entre la producción de muestras y la producción en masa. Deje rápidamente que sus productos ocupen el mercado.

Para proyectos personalizados, Nuestro equipo profesional lo ayudará a lograr los mejores productos en términos de calidad y eficiencia..

Toda la información y los materiales cargados son seguros y confidenciales..

The printed surface is rough

Performance: The surface of printed metal parts has obvious graininess, no suave.

reason: Improper printing parameter settings, If the layer thickness is too large, Laser power is low etc.; Poor quality powder, Uneven particle size.

Solución

Optimize printing parameters, Reduce layer thickness, Aumentar la potencia láser; Choose better quality powder, Ensure particle size is uniform.

Post-process prints, such as polishing, Polishing etc., Improve surface finish.

Part deformation

Performance: The printed part is bent, Distortion and other deformation phenomena.

reason: Uneven temperature during printing, generate internal stress; The support structure design is unreasonable.

Solución

Optimize printing parameters, Control temperature uniformity during printing, Reduce internal stress; Proper design of support structures, Increase part stability.

Heat treatment of printed parts, Eliminate internal stress.

Printing failed

Performance: Interruption during printing, Part cannot be completely formed.

reason: Equipment failure, Such as laser system failure, Powder supply issues, etc.; The model design is unreasonable, There is a structure that cannot be printed.

Solución

Check equipment, Troubleshooting; Ensure model design is reasonable, Avoid unprintable structures.

Fully simulate and test before printing, Ensure the smooth progress of the printing process.

Low material utilization rate

Performance: A lot of metal powder is wasted during the printing process.

reason: Printing parameter settings are unreasonable, Resulting in underutilization of powder; Incomplete powder recovery system.

Solución

Optimize printing parameters, Improve powder utilization; Improve powder recovery system, Recycle unused powder for reuse

Reasonably design the placement and support structure of parts, Reduce powder waste.

Nuestros servicios de mecanizado CNC han sido elogiados por clientes globales de diferentes campos, Suministramos componentes de mecanizado CNC a una variedad de industrias, Cubre lo siguiente y más.

Piezas de gran tamaño, Como los parachoques ABS mecanizados CNC, Paneles de instrumentos PC/ABS y piezas automotrices de precisión, Reflector, por ejemplo,, lente, Ensamblaje del volante, motor, transmisión.

Piezas de robot para la industria de robótica y automatización, solenoide, efector final, Motor, Equipo de control automático, Accesorios y carcasas.

Acero inoxidable o placa de hueso de titanio, prótesis, equipo respiratorio, dispositivo portátil, equipo de diagnóstico, modelo anatómico, Componentes para necesidades médicas como instrumentos quirúrgicos.

Motor aerodinámico, cuerpo, turbina, freno, piezas de neumáticos, sistema de iluminación, Bomba de vacío y piezas de bomba de combustible.

Productos de consumo, como carcasas de equipos electrónicos, botón, manejar, Perilla, cambiar, dispositivos digitales portátiles, Productos de cocina, equipo deportivo.

Nuevos componentes de la industria energética, p.ej. intercambiador de calor, válvula, tubería, Bombas y accesorios, Componentes hidráulicos, Componentes de la batería, componentes del panel solar, Marco e impulsor.

Vivienda electrónica, cinta transportadora, cierre, conector, Componentes del generador, accesorios, Piezas de máquina y herramientas para maquinaria industrial.

Se pueden crear modelos reales en función de los requisitos de semiconductores, Modelos de ingeniería y otros equipos experimentales, Trabajamos con universidades de todo el mundo.