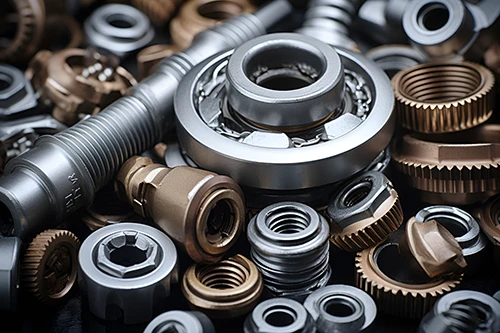

Precision hardware parts processing

Atender

Precision hardware parts refer to high-precision, Metal parts with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and machinery, Plays a key role in product performance and quality.

Prototipo de mecanizado CNC único

Our precision hardware parts processing capabilities

Choose Rapidefficient Precision Hardware Parts, The reasons are as follows: Primero, high precision, Able to meet high requirements on part size and shape, Ensure precise product fit and performance. Second, high production efficiency, Advanced manufacturing processes and technologies enable rapid mass production, Acortar ciclo de entrega. Third, reliable quality, Using high-quality materials and strict quality control, Parts have good durability and stability. Fourth, it can be customized, Parts with complex shapes and structures can be customized according to different needs. In short, It is ideal for many high-end manufacturing areas.

Choose Rapidefficient Precision Hardware Parts, The reasons are as follows: Primero, high precision, Able to meet high requirements on part size and shape, Ensure precise product fit and performance. Second, high production efficiency, Advanced manufacturing processes and technologies enable rapid mass production, Acortar ciclo de entrega. Third, reliable quality, Using high-quality materials and strict quality control, Parts have good durability and stability. Fourth, it can be customized, Parts with complex shapes and structures can be customized according to different needs. In short, It is ideal for many high-end manufacturing areas.

Precision hardware parts refer to high-precision, Metal parts with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and machinery, Plays a key role in product performance and quality.

Precision hardware parts can be classified according to their functions and uses, Mainly includes connecting parts, Transmission parts, Support parts, etc., connecting parts such as bolts, nut, Rivets etc., For connecting different parts; Transmission parts such as gears, rack, Lead screw, etc., Used to transmit power and movement; Support parts such as bearing seats, Bracket, Shell etc., Used to support and protect other parts.

Common precision hardware parts processing methods include CNC processing, estampado, casting, forging, EDM, etc..

Electronic equipment hardware

Good at producing mobile phones, Precision hardware casings for computers and other electronic equipment, Connectors, etc., Alta precisión, Excellent quality.

Automobile hardware accessories

Manufacturing car engines, Hardware parts for chassis and other parts, Resistencia al desgaste, Alta fuerza.

Medical equipment hardware

Production of precision hardware structural parts for medical instruments, Meet strict hygiene standards.

Aerospace hardware

Providing high strength to the aerospace industry, High precision hardware parts.

Precision mold hardware

Good at making hardware accessories in molds, Guarantee mold accuracy and life.

Communication equipment hardware

Production of hardware casings and internal structural parts for communication equipment, Signal is stable.

The display of precision hardware parts is stunning. High precision screws, Nuts and other fasteners, Exquisite gears, Shaft parts, Smooth as a mirror. Complex and exquisite structure, Reflect advanced manufacturing technology, Applicable to multiple high-end fields, Highlight the beauty of technology and craftsmanship.

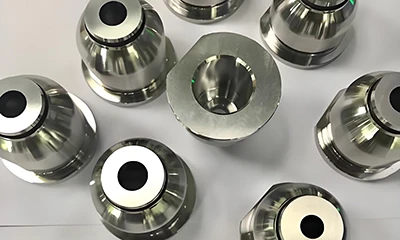

High dimensional accuracy, Ensure precise fit with other components, Improve overall product performance.

Material is hard, Can withstand large external forces, Ensure products operate stably in harsh environments.

Resistente a la corrosión, Resistente al desgaste, Long service life, Reduce product maintenance costs.

Understand the uses and needs

Clarify the specific role of precision hardware parts in products, Determine the required accuracy, strength, Corrosion resistance and other performance requirements. Por ejemplo, in electronic devices, High-precision connection parts may be required to ensure stable signal transmission; in mechanical equipment, High-strength transmission parts may be required to withstand larger loads.

Elija el material correcto

Common precision hardware materials include stainless steel, Aleación de aluminio, Copper etc., Stainless steel has good corrosion resistance and strength; Aluminum alloy is lightweight, Good thermal conductivity; Copper has excellent electrical conductivity. Choose appropriate materials according to specific application scenarios, Also consider cost factors.

Design and processing

1. Consider part manufacturability when designing, Avoid overly complex shapes and structures. Reasonable design tolerances, Ensure parts fit smoothly during assembly.

2. Choose a professional processing manufacturer, They usually have advanced processing equipment, Such as CNC machining center, EDM machine, etc., Processing parameters must be strictly controlled during processing, Ensure dimensional accuracy and surface quality.

Inspección de calidad

1. Strict quality inspection of precision hardware parts, Includes dimensional measurements, Appearance inspection, Hardness test, Material composition analysis, etc..

2. Use high-precision testing equipment such as three-dimensional coordinate measuring machines, Ensure the dimensional accuracy of parts meets requirements.

Tratamiento superficial

Surface treatment of parts as required, Such as electroplating, Spray, Oxidation, etc., To improve the corrosion resistance of parts, Aesthetics and wear resistance.

Packaging and storage

1. Use appropriate packaging, Protect parts from damage during shipping and storage.

2. Storage environment should be dry, clean, Avoid parts getting wet, Rusted or otherwise contaminated.

Si necesita un pequeño número de piezas o 10000 Múltiples objetos de producción que finalmente se usan, CNC Machining es un método de fabricación ideal. Los siguientes son los servicios CNC personalizados que lanzamos.

Por efecto rápido, Puede completar la fabricación de productos en poco tiempo, para poder ingresar rápidamente al mercado.

La fabricación de moho eficiente es una forma rentable, Capaz de cerrar la brecha entre la producción de muestras y la producción en masa. Deje rápidamente que sus productos ocupen el mercado.

Para proyectos personalizados, Nuestro equipo profesional lo ayudará a lograr los mejores productos en términos de calidad y eficiencia..

Toda la información y los materiales cargados son seguros y confidenciales..

Dimensional deviation: Actual production part size does not match design size

Reason: Insufficient accuracy of processing equipment, Desgaste de herramientas, Improper setting of process parameters, etc..

Solución

Regular inspection and maintenance of processing equipment, Asegurar la precisión del equipo.

Reemplace las herramientas desgastadas de inmediato, Choose the right tool type and size.

Optimize process parameters, Continuous adjustment through trial processing, to achieve optimal dimensional accuracy.

Surface quality issues: Scratches appear on the surface of the part、glitch、Rust spots, etc..

Reason: Improper operation during processing, Inappropriate tool selection, Poor storage environment, etc..

Solución

Standardize processing operation procedures, Avoid surface damage caused by human factors.

Choose appropriate tools based on part material and processing requirements, Improve the quality of machined surfaces.

Improve storage environment, Take anti-rust measures, Such as applying anti-rust oil, Use rust-proof packaging, etc..

Insufficient strength: Parts are prone to breakage or deformation during use

Reason: Improper material selection, The heat treatment process is unreasonable, There are defects in the design structure, etc..

Solución

Reasonable selection of materials, Select hardware materials with appropriate strength according to the use requirements of the parts and the working environment.

Optimize heat treatment process, Improve material hardness and strength.

Optimize the design structure, Avoid stress concentrations, Improve the overall strength of the part.

Assembly issues: Parts do not fit together smoothly during assembly,The gap is too large or too small, etc..

Reason: Inaccurate dimensional tolerance control, Processing accuracy is not enough, Unreasonable assembly process, etc..

Solución

Strictly control dimensional tolerances, Improve machining accuracy, Ensure fit accuracy between parts.

Optimize assembly process, Use appropriate assembly tools and methods, Ensure the assembly process runs smoothly.

Fully consider assembly requirements during the design phase, Properly design the size and shape of parts, to facilitate assembly.

Nuestros servicios de mecanizado CNC han sido elogiados por clientes globales de diferentes campos, Suministramos componentes de mecanizado CNC a una variedad de industrias, Cubre lo siguiente y más.

Piezas de gran tamaño, Como los parachoques ABS mecanizados CNC, Paneles de instrumentos PC/ABS y piezas automotrices de precisión, Reflector, por ejemplo,, lente, Ensamblaje del volante, motor, transmisión.

Piezas de robot para la industria de robótica y automatización, solenoide, efector final, Motor, Equipo de control automático, Accesorios y carcasas.

Acero inoxidable o placa de hueso de titanio, prótesis, equipo respiratorio, dispositivo portátil, equipo de diagnóstico, modelo anatómico, Componentes para necesidades médicas como instrumentos quirúrgicos.

Motor aerodinámico, cuerpo, turbina, freno, piezas de neumáticos, sistema de iluminación, Bomba de vacío y piezas de bomba de combustible.

Productos de consumo, como carcasas de equipos electrónicos, botón, manejar, Perilla, cambiar, dispositivos digitales portátiles, Productos de cocina, equipo deportivo.

Nuevos componentes de la industria energética, p.ej. intercambiador de calor, válvula, tubería, Bombas y accesorios, Componentes hidráulicos, Componentes de la batería, componentes del panel solar, Marco e impulsor.

Vivienda electrónica, cinta transportadora, cierre, conector, Componentes del generador, accesorios, Piezas de máquina y herramientas para maquinaria industrial.

Se pueden crear modelos reales en función de los requisitos de semiconductores, Modelos de ingeniería y otros equipos experimentales, Trabajamos con universidades de todo el mundo.