How to choose the mechanical processing method? 4 tips to find the right solution

In the manufacturing industry, the choice of machining method is directly related to product quality and production efficiency. Faced with...

Comparison of machining methods:Explore the balance between efficiency and precision

In the vast world of manufacturing, there are many different material processing methods, each with its own characteristics. From traditional...

Advantages of CNC turning:Reshaping efficiency and precision in manufacturing

In the ever-changing manufacturing industry,CNC (computer numerical control) technology is known for its high efficiency、Precise features,Leading changes in the industry。CNC...

CNC turning:Reinventing the precision art of manufacturing

In the ever-changing manufacturing industry,CNC (computer numerical control) technology is driving changes in the industry at an unprecedented rate。in,CNC turning...

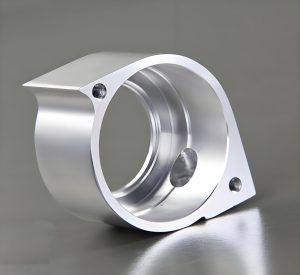

Mecanizado de precisión,Make your products more attractive

In the wave of modern manufacturing,Precision machining has become an important criterion for measuring product quality and process level.。This article...

CNC technology:Leading a new era of CNC aluminum parts processing

In the rapid development of modern manufacturing industry,CNC technology with its high precision、High efficiency features,It is gradually becoming an important...

High quality aluminum parts:A solid foundation for manufacturing

In the rapid development of modern manufacturing industry,High-quality aluminum parts are characterized by their light weight、High strength、Corrosion resistance and other...

CNC aluminum parts processing:Empowering innovative power in applications in multiple fields

In the wave of modern manufacturing,CNC aluminum parts processing with its high precision、High efficiency features,It has become an indispensable processing...

Professional supplier of injection molding:The power of innovation to shape the future

In today’s era of rapid changes in manufacturing,Injection molding technology is known for its high efficiency、Flexible and precise features,Become an...

Diversity and innovative applications of injection molding materials

In the vast world of manufacturing, injection molding technology has become an important force in product molding and promoting industrial...

Injection molding advantages:Efficiency and innovation that shape the future

In the ever-changing manufacturing industry,Injection molding technology with its unique advantages,Become a product shape、An important force in promoting industrial upgrading。This...

Injection molding applications:Shape the miracle of craftsmanship with infinite possibilities

In today’s broad arena of manufacturing,The injection molding process is characterized by its unique applicability and efficiency,Become a product shaper、An...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introducción en los últimos años, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

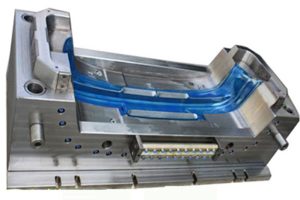

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

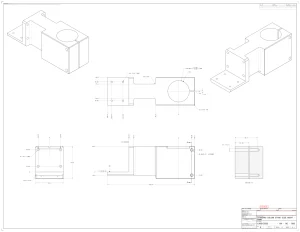

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

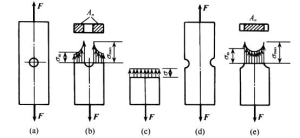

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

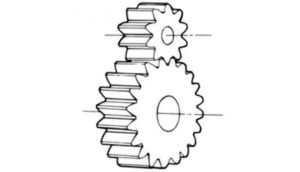

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

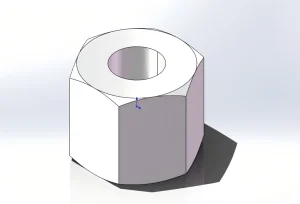

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

Unleashing the Cost Efficiency of CNC Machining Aluminum with Rapidefficient

一、Introduction In the realm of CNC machining aluminum, Rapidefficient emerges as a game-changer. Cost efficiency in CNC machining holds paramount...

CNC Machining for Aluminum Enclosures: Excellence in Precision Engineering

1. Introduction In the realm of modern manufacturing, CNC machining has revolutionized the production of aluminum enclosures. These enclosures serve...

Aluminum CNC Prototyping: Revolutionizing Product Development with Rapidefficient

1. Introduction In the highly competitive landscape of modern manufacturing, Aluminum CNC prototyping has emerged as a cornerstone for innovation...

Unleashing the Power of CNC Aluminum Parts Manufacturing with Rapidefficient

1、Introduction In today’s rapidly evolving industrial landscape, CNC aluminum parts manufacturing plays a crucial role. This article aims to provide...

CNC Aluminum Machining Services: Unleashing Precision and Efficiency

Introduction Overview of CNC Aluminum Machining CNC aluminum machining is a highly sophisticated and essential process in various industries. This...

High-Precision Aluminum CNC Machining: A Comprehensive Overview

1、Introduction to High-Precision Aluminum CNC Machining High-precision aluminum CNC machining is a crucial process in modern manufacturing. It involves the...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...

-1024x546-1-300x160.webp)

-1024x546-1-300x160.webp)

-1024x546-1-300x160.webp)