What is the Difference Between CNC Machining and Precision Machining?

In modern manufacturing, both CNC machining and precision machining are essential processes. While they often overlap, they serve different purposes...

What is the Hardest Material to CNC Machining?

CNC machining is an essential process in modern manufacturing. It allows for precise shaping and cutting of various materials. Sin embargo,...

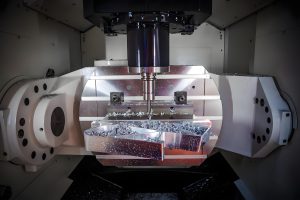

What Are the Six Main Types of CNC Machines?

CNC machines have revolutionized manufacturing by automating and improving the accuracy of various machining processes. There are several types of...

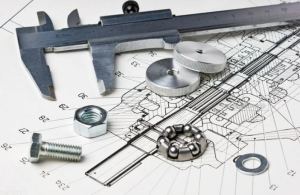

What is the Difference Between Precision Machining and Non-Precision Machining?

Machining is a fundamental process in manufacturing. Sin embargo, there are two main types of machining: precision and non-precision. Each serves...

What is Precision Machining?

Precision machining technology is a manufacturing process that shapes raw materials into exact specifications. It plays a crucial role in...

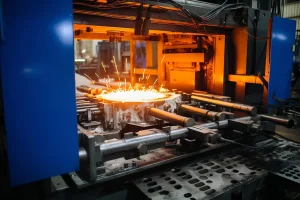

Five Key Steps of Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts. From everyday household items to intricate automotive components,...

What Plastic Is Used in Injection Molding?

Injection molding is a widely-used process in manufacturing, particularly for creating plastic parts and products. The choice of plastic is...

What Is the Process of Sheet Metal Processing?

Sheet metal processing is a crucial process in manufacturing, where flat metal sheets are transformed into functional parts and products....

Why Is Injection Molding So Popular?

Injection molding is a manufacturing process that has gained widespread popularity in various industries. From creating small, detailed parts to...

What are the 4 types of sheet metal processing operations?

Sheet metal processing plays a crucial role in creating parts and products for various industries. To turn flat metal sheets...

Applications of Overmolding

Overmolding is a versatile manufacturing process. It combines two or more materials into a single part. This technique offers numerous...

Advantages of Overmolding

Overmolding is a unique manufacturing process. It involves combining two or more materials into one product. This technique offers various...

Post-processing of SLS Printed Parts

I. Introducción en los últimos años, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introducción en los últimos años, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

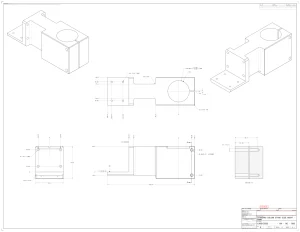

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

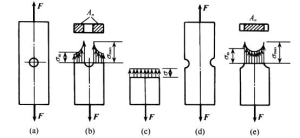

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

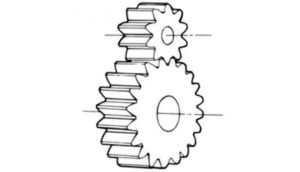

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

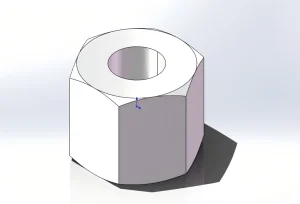

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

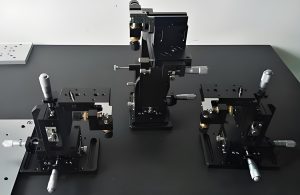

Piezas de comunicación óptica Mecanizado CNC Solución rápida

I. Introducción en la era digital, La comunicación óptica se ha convertido en la columna vertebral de la conectividad global. Desde acceso a Internet de alta velocidad a ...

Solución rápida para mecanizado CNC de piezas de semiconductores

I. Introducción en el panorama altamente competitivo de la industria electrónica, Las piezas de semiconductores se encuentran como el eje del avance tecnológico ....

Nuevas piezas de energía CNC Mecanizado Solución rápida

I. Introducción en los últimos años, con el rápido desarrollo de nuevas tecnologías energéticas, La demanda de nuevas piezas de energía tiene ...

Solución rápida para piezas médicas de mecanizado CNC

1. Introducción en los últimos años, La industria médica ha sido testigo de un notable crecimiento, con una creciente demanda de sofisticado y preciso..

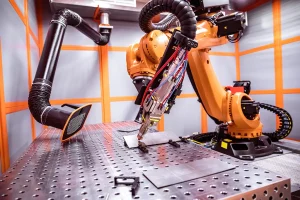

Robot Piezas de mecanizado CNC Solución rápida

Ⅰ. Introducción en los últimos años, El campo de la robótica ha sido testigo de avances notables, revolucionando industrias en todo el mundo. De Automotive ...

Tecnología de mecanizado CNC de piezas de carcasa de paredes delgadas con fácil deformación: Soluciones de alta velocidad

I. Introducción Piezas de concha de paredes delgadas,con su diseño liviano y compacto, se han vuelto omnipresentes en varias industrias. De componentes aeroespaciales que ...

Aplicación de mecanizado CNC de alta velocidad en la fabricación de piezas de aeronaves

I. Introducción en el reino altamente avanzado de la fabricación de aviones, La precisión y la eficiencia no son solo rasgos deseables sino absolutos ....

Descripción general: Tipos de resortes y sus aplicaciones

Ballestas: Una introducción son componentes mecánicos ubicuos que juegan un papel crucial en la vida moderna. Son objetos elásticos..

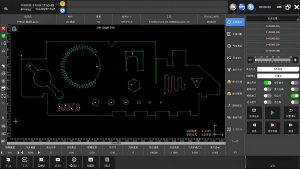

Tecnología y flujo de procesamiento de piezas

El núcleo de la tecnología de procesamiento de piezas, ¿cuál es la tecnología de procesamiento de piezas? Tecnología de procesamiento de piezas es la piedra angular de la fabricación moderna,...

CNC Machining of Aluminum Alloy Material

The Basics of Aluminum Alloy in CNC Machining What is Aluminum Alloy? Aluminum alloy is a material composed mainly of...

Three Factors Affecting the Machining Accuracy of CNC Milling Machine and Four Solutions

1、Introduction to CNC Milling Machine Machining Accuracy 1. Briefly introduce what CNC milling machine machining accuracy means and its importance...

CNC solutions from Rapidefficient suppliers

In the ever-evolving landscape of manufacturing, La precisión y la eficiencia son primordiales. This is where CNC (Control numérico de la computadora) solutions come...

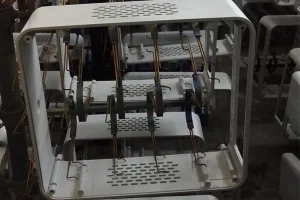

RapidEffient crea un estuche de computadora en miniatura para TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...