Understand how to solve the problems encountered during precision parts processing?

Precision parts processing is a demanding manufacturing process that requires the use of advanced processing technology and equipment to ensure...

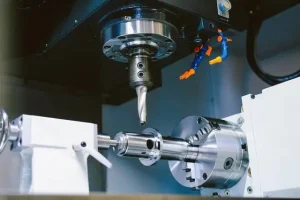

What is the main working principle of CNC turning and milling?

CNC turning and milling composite machining refers to the use of CNC systems to control the movement of workpieces between...

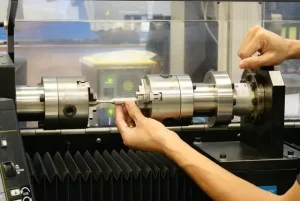

How to check abnormal problems during CNC turning and milling?

Checking abnormal problems that occur during CNC turning and milling can be done from the following aspects: 1. Equipment inspection:...

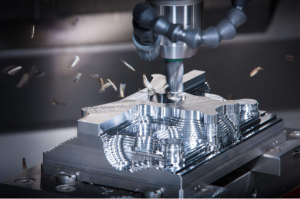

What are the forms of precision CNC machining?

There are various forms of precision CNC machining to meet the processing needs of different workpieces and materials. The following...

What are the requirements for the specifications and dimensions of stainless steel parts processing?

The specifications and size requirements of stainless steel parts processing are mainly affected by multiple factors, including the material properties...

Analysis of the reasons affecting the poor quality of precision CNC machining materials?

Operator quality and skills 1. Insufficient skill level: Precision CNC processing technology requires operators to have high professional skills and...

Do you want to know the development trend of precision parts processing?

1. Intelligence With the rapid development of technologies such as artificial intelligence and the Internet of Things, the precision parts...

What should be paid attention to in the polishing operation of precision parts?

1. Preliminary preparation Tool and material selection: Precision parts processing selects appropriate polishing tools according to the material, shape and...

How to control deformation during the processing of stainless steel parts?

In the process of stainless steel parts processing, controlling deformation is an important link, which directly affects the quality and...

How to solve the surface wear of precision CNC machined parts?

In precision CNC machining, wear on the surface of parts is a common problem, which may be caused by a...

How to reduce scrap rate during precision CNC machining?

Reducing the scrap rate during precision CNC machining is the key to improving production efficiency, ensuring product quality and reducing...

How to prevent pits when processing non-standard hardware parts?

In the process of non-standard hardware parts processing, preventing pits is an important quality control link. The following are some...

CNC Milling Machine: Ideal for Processing Which Parts?

I. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

I. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

I. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

I. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

I. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...