Do you want to know the development trend of precision parts processing?

1. Intelligence With the rapid development of technologies such as artificial intelligence and the Internet of Things, the precision parts...

What should be paid attention to in the polishing operation of precision parts?

1. Preliminary preparation Tool and material selection: Precision parts processing selects appropriate polishing tools according to the material, shape and...

How to control deformation during the processing of stainless steel parts?

In the process of stainless steel parts processing, controlling deformation is an important link, which directly affects the quality and...

How to solve the surface wear of precision CNC machined parts?

In precision CNC machining, wear on the surface of parts is a common problem, which may be caused by a...

How to reduce scrap rate during precision CNC machining?

Reducing the scrap rate during precision CNC machining is the key to improving production efficiency, ensuring product quality and reducing...

How to prevent pits when processing non-standard hardware parts?

In the process of non-standard hardware parts processing, preventing pits is an important quality control link. The following are some...

What are the requirements for analyzing the surface quality of non-standard hardware parts processing workpieces?

1. Surface finish and flatness No defects: The surface of non-standard hardware parts processing workpieces should be free of obvious...

What are the requirements for material selection in precision parts processing?

1. Physical performance requirements Hardness Processing adaptability: For precision parts processing, the material hardness should be moderate. If the material...

How to avoid contamination and damage during precision CNC machining?

In the process of precision CNC machining, avoiding contamination and damage is essential to ensure machining quality and equipment life....

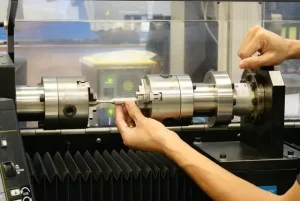

How to solve the problem of inconvenient loading and unloading of workpieces during processing of imported CNC lathes?

During the processing of imported CNC lathes, the inconvenience of loading and unloading workpieces can be solved by the following...

Understand the common processing difficulties in the processing of stainless steel parts?

There are many difficulties in the processing of stainless steel parts due to their material characteristics and process requirements, which...

What factors affect the efficiency of CNC turning and milling?

There are many factors that affect the efficiency of CNC turning and milling, including equipment performance, cutting tools, process parameters,...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

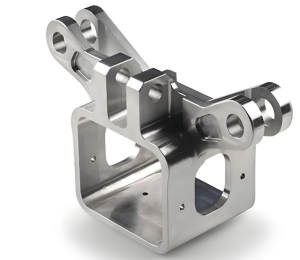

Processing technology of shaft parts

Shaft parts are essential components in numerous mechanical and industrial applications. Their proper processing is crucial to ensure the smooth...

The role of nickel plating on aluminum alloy

Aluminum alloy is a widely used material in various industries due to its excellent properties such as lightweight, good conductivity,...

Advantages and disadvantages of CNC machining hardware parts

En la industria manufacturera moderna, CNC machining has become a crucial process for producing high-quality hardware parts. CNC (Computer Numerical...

How to improve UAV parts processing efficiency and reduce waste

In today’s rapidly evolving technological landscape, unmanned aerial vehicles (UAVs) have become increasingly popular in various fields such as surveillance,...

Precision machining technology and process for mold parts

In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in...

Sheet metal stamping technology and application

Sheet metal stamping technology is a crucial manufacturing process that has been widely used in various industries. In this article,...

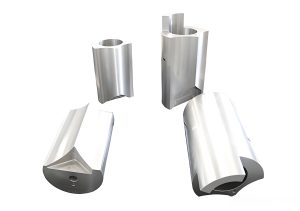

Challenges and Advances in Irregularly Shaped Parts Processing

Introduction The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts...

6 Essential Knowledge Points for Stainless Steel Machining

Introduction: Stainless steel machining is a critical process in many industries, from aerospace to medical devices. Its high strength, durability,...

Detailed explanation of CNC machining accuracy

1. Introduction to CNC Machining Accuracy CNC (Control numérico de la computadora) machining has become one of the most crucial methods of...

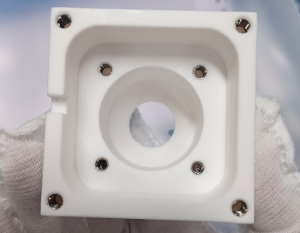

Applications of Teflon Materials in the Machining Industry

Introduction: Teflon, a brand name for polytetrafluoroethylene (PTFE), has gained widespread popularity in the machining industry due to its exceptional...

CNC Bending: Revolutionizing Metalworking

1、Introduction CNC bending, short for computer numerical control bending, is a revolutionary technology in the field of metalworking. It has...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

RapidEffient crea un estuche de computadora en miniatura para TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...