Introduction

CNC machining can directly achieve a high-gloss mirror finish.

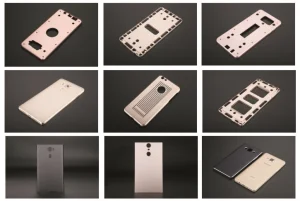

Currently, high-gloss CNC machining has become increasingly common, especially in the consumer electronics industry. In the past, demand was relatively low, so only a few manufacturers mastered this process. Today, it is widely applied in industries such as smartphones, laptops, and high-end digital products.

Tool Geometry and Cutting Principles

High-gloss milling cutters have a wide cutting edge and employ a small or negative rake angle and a near-zero rake angle. During high-gloss milling, the tool performs high-speed cutting. Furthermore, due to the small rake angle, the cutting edge scrapes and squeezes the surface, resulting in a high-quality finish and an oxide layer, which improves the surface hardness and wear resistance of the component.

In addition to being related to the geometry of the component, the tool geometry is also primarily determined by the physical properties of the component material.

- Plastic materials (aluminum, copper, nickel): tool rake angle 0° to +15°, clearance angle 5–10°, tool nose radius 0.5–5 μm.

- Brittle materials (silicon, germanium, CaF₂, ZnS): tool rake angle -15° to -45°.

The optimal rake angle depends not only on the material itself but also on the rigidity of the equipment’s clamping system and is best determined through production testing.

High-Gloss Milling Tools

For high-gloss milling, a disc milling cutter should be used. The diameter of the cutter disc should be as large as possible based on the size of the surface being milled, and the blades should have good rigidity and positioning accuracy. The size of the cutter disc will affect the texture and effect of the milled surface. The number of blades can be single or multiple, but multiple blades make it more difficult and time-consuming to adjust each blade. Using a single cutter will yield better results.

Diamond cutting tools may appear expensive and require a large initial investment, but natural diamonds are extremely hard and wear-resistant. According to incomplete statistics, the lifespan of diamond turning tools is about 25 times that of ordinary high-speed steel turning tools. Each diamond tool can be resharpened 6 a 15 veces, so the tooling cost per part is actually minimal, and stable dimensions and a higher finish are achieved.

Parts and Materials

Materials most suitable for high-gloss machining include aluminum, copper, and magnesium alloys.

- Aluminio: very bright finish, minimally abrasive to the tool.

- Copper: relatively bright finish, less abrasive to the tool.

- Stainless steel: matte gray finish, significant tool wear, usually requires secondary polishing.

For this reason, stainless steel is not commonly used for decorative high-gloss machining.

Tecnología de procesamiento

The cutting speed for mirror milling is generally expressed in meters per minute (m/min). In practice, ultra-high spindle speeds (tens of thousands of revolutions per minute) are required, combined with carefully controlled feed rates and tool nose radii to achieve the best surface finish.

To produce high-quality components, the spindle must be dynamically balanced after tool changes to minimize surface ripples caused by dynamic imbalance. Diamond tools have excellent heat conductivity and low cutting volumes, so in most cases, no coolant is required. In fact, dry cutting is preferred when machining aluminum and copper. In some cases, micro-lubrication (MQL) or gas cooling may be applied, but excessive liquid coolant increases the complexity of cleaning and may lead to tool-edge chipping when mixed with chips.

The disadvantage of high-gloss machining is that it requires a very high and stable product profile; otherwise, the finish will be uneven. Obtaining process parameters that encompass all relevant factors and achieving the optimal combination often requires a process of trial and error.

Áreas de aplicación

In many countries, there is a clear trend toward high-gloss finishes on components.

- Aluminum sheets: widely used in casings of digital products; after high-gloss finishes, they can undergo secondary oxidation to increase wear resistance.

- Stainless steel: used in high-end digital cameras and communications equipment, though usually produces a matte gloss rather than a true mirror finish.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive, and office automation parts.

The company’s CNC machining centers include four-axis, five-axis, and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers, and other precision testing equipment.

- Machining accuracy: arriba a 0.01 mm

- Testing accuracy: arriba a 0.001 mm