Procesamiento de corte de cables

Atender

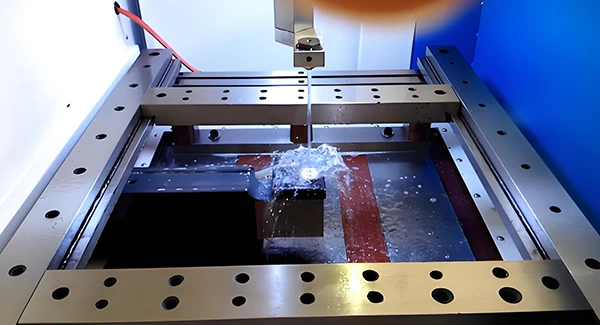

Wire cutting is a processing method that uses the principle of electric spark discharge to cut conductive materials.

Prototipo de mecanizado CNC único

Our wire EDM parts capabilities

Choose Rapidefficient Wire EDM, Because of its high precision, Can process complex shapes, fine structure; Wide adaptability to materials, Can process a variety of conductive materials; And it is non-contact processing, Avoid force deformation of workpiece, Can guarantee surface quality, Comprehensive advantages are significant.

Wire cutting is a processing method that uses the principle of electric spark discharge to cut conductive materials. during processing, A thin metal wire (usually molybdenum or brass) as an electrode, Apply pulse voltage between workpiece and wire electrode, spark discharge. The high temperature of the electric spark locally melts and vaporizes the workpiece material, To achieve material cutting.

“Applicable material types

Acero: Including various carbon steels, Alloy steel and stainless steel, etc., Steel has good mechanical properties and processability, Is one of the most commonly used materials in wire cutting processing. ”

aluminum: Aluminum and its alloys are lightweight, Good thermal conductivity and other characteristics, Widely used in aerospace, Automobile manufacturing and other fields. Wire-cut machining can easily process various aluminum parts with complex shapes.

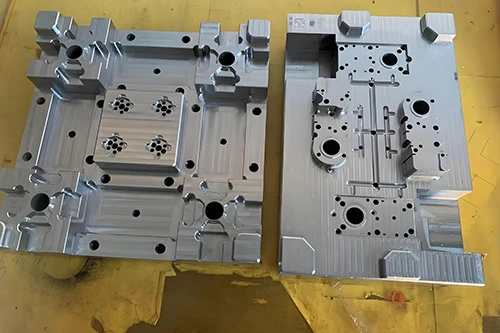

Mold making

Capable of processing complex molds with high precision, Such as injection mold, Stamping die, etc., Ensure mold accuracy and quality.

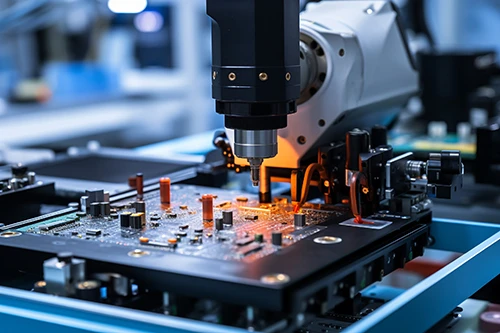

Precision parts

Good at processing electronics, Precision parts in medical and other fields, High dimensional accuracy, Good surface quality.

Special-shaped parts processing

Can process various special-shaped parts, Meet special design needs, High shape accuracy.

Hard material processing

Good processing effect on cemented carbide and other materials, Even parts with high hardness can be handled easily.

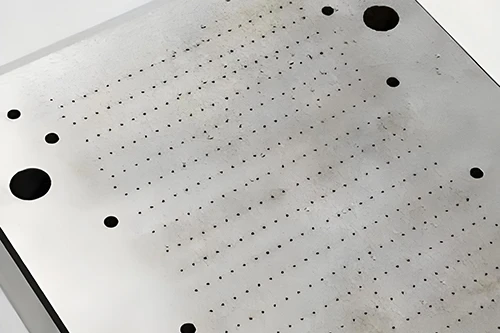

Small hole processing

Micro hole processing possible, Alta precisión, Suitable for precision instruments and other fields.

New product development

Provide rapid development of new products, High-precision sample processing services.

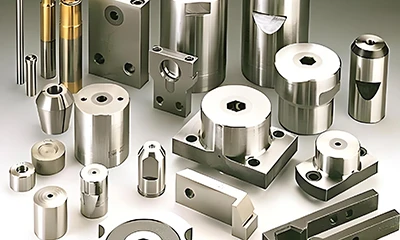

Display of wire cutting parts, Alta precisión, Complex and diverse shapes, Smooth surface, Highlight the charm of advanced processing technology.

Able to achieve micron-level precision processing, Ensure part dimensions are accurate, For demanding applications.

Can process various complex shape parts, Not limited by traditional processing.

Can process a variety of conductive materials, Adaptable.

Understand the wire cutting process

Wire cutting machining uses electric spark discharge between the electrode wire and the workpiece, A processing method that removes workpiece material. Be familiar with its principles, Category (fast wire、Slow moving wire, etc.) and scope of application.

Determine processing needs

Clarify the specific requirements for the parts to be processed, including dimensional accuracy, shape complexity, Surface roughness, etc., Consider the function of the parts in the product and the environment in which they are used.

Choose the right equipment

Based on part requirements and budget, Choose the right wire cutting equipment. Fast wire-traveling equipment costs less but has slightly lower accuracy, Slow wire moving equipment has high precision but is expensive.

Design and programming

1. When designing parts, Consider the process characteristics of wire cutting processing, Avoid difficult-to-machine structures. Reasonable design of machining allowance, Threading holes, etc..

2. Use professional wire cutting programming software, Convert part design into machining code. Ensure programming accuracy and efficiency.

Process control

1. Install workpiece and electrode wire, Make sure the installation is secure and in the correct position.

2. Set appropriate processing parameters, Such as discharge current, pulse width, Velocidad de alimentación, etc., According to material, Thickness and other factors can be adjusted.

3. Monitor the machining process, Pay attention to the wear of the electrode wire, Discharge status, etc., Adjust parameters or replace electrode wire in time.

Inspección de calidad

1. Comprehensive quality inspection of finished parts, Includes dimensional measurements, Shape check, Surface roughness testing, etc..

2. Use measuring tools, Microscope and other testing equipment, Ensure parts meet quality standards.

Postprocesamiento

Post-process as needed, Such as deburring, polishing, Cleaning etc., Improve the appearance quality and performance of parts.

Packaging and storage

Use appropriate packaging, Prevent parts from being damaged during shipping and storage. Storage environment should be dry, clean, Avoid parts getting wet, rust.

Si necesita un pequeño número de piezas o 10000 Múltiples objetos de producción que finalmente se usan, CNC Machining es un método de fabricación ideal. Los siguientes son los servicios CNC personalizados que lanzamos.

Por efecto rápido, Puede completar la fabricación de productos en poco tiempo, para poder ingresar rápidamente al mercado.

La fabricación de moho eficiente es una forma rentable, Capaz de cerrar la brecha entre la producción de muestras y la producción en masa. Deje rápidamente que sus productos ocupen el mercado.

Para proyectos personalizados, Nuestro equipo profesional lo ayudará a lograr los mejores productos en términos de calidad y eficiencia..

Toda la información y los materiales cargados son seguros y confidenciales..

Poor surface roughness: The surface of the processed parts is rough, Unsatisfactory finish

Reason: Discharge parameters are unreasonable, Electrode wire wear, Working fluid pollution, etc..

Solución

Optimize discharge parameters, Reduce discharge current and pulse width, Increase pulse frequency.

Replace worn electrode wire promptly, Keep the electrode wire in good condition.

Change working fluid regularly, Ensure the cleanliness of the working fluid.

Dimensional deviation: Hay una diferencia entre el tamaño de procesamiento real y el tamaño de diseño.

Reason: error de programación, Machine tool accuracy issues, Electrode wire tension is unstable, etc..

Solución

Código de programación de doble verificación, Make sure programming is correct.

Regularly perform accuracy testing and adjustments on machine tools, Ensure the accuracy of machine tools.

Stable electrode wire tension, Use equipment such as tension adjusters.

Disconnected: The electrode wire suddenly broke during processing

Reason: Electrode wire quality issues, Discharge parameters are too large, There are hard points inside the workpiece, etc..

Solución

Choose good quality electrode wire, Avoid using poor quality electrode wire.

Reduce discharge parameters, Avoid excessive discharge energy causing electrode wire breakage.

Preprocess workpieces, Remove impurities such as hard spots.

Shape error: The shape of the processed parts does not match the designed shape

Reason: error de programación, Machine tool accuracy issues, Electrode wire shaking, etc..

Solución

Código de programación de doble verificación, Ensure programming is accurate.

Perform accuracy inspection and adjustment on machine tools, Improve the motion accuracy of machine tools.

Take measures to reduce the vibration of the electrode wire, Such as using guide devices, etc..

Nuestros servicios de mecanizado CNC han sido elogiados por clientes globales de diferentes campos, Suministramos componentes de mecanizado CNC a una variedad de industrias, Cubre lo siguiente y más.

Piezas de gran tamaño, Como los parachoques ABS mecanizados CNC, Paneles de instrumentos PC/ABS y piezas automotrices de precisión, Reflector, por ejemplo,, lente, Ensamblaje del volante, motor, transmisión.

Piezas de robot para la industria de robótica y automatización, solenoide, efector final, Motor, Equipo de control automático, Accesorios y carcasas.

Acero inoxidable o placa de hueso de titanio, prótesis, equipo respiratorio, dispositivo portátil, equipo de diagnóstico, modelo anatómico, Componentes para necesidades médicas como instrumentos quirúrgicos.

Motor aerodinámico, cuerpo, turbina, freno, piezas de neumáticos, sistema de iluminación, Bomba de vacío y piezas de bomba de combustible.

Productos de consumo, como carcasas de equipos electrónicos, botón, manejar, Perilla, cambiar, dispositivos digitales portátiles, Productos de cocina, equipo deportivo.

Nuevos componentes de la industria energética, p.ej. intercambiador de calor, válvula, tubería, Bombas y accesorios, Componentes hidráulicos, Componentes de la batería, componentes del panel solar, Marco e impulsor.

Vivienda electrónica, cinta transportadora, cierre, conector, Componentes del generador, accesorios, Piezas de máquina y herramientas para maquinaria industrial.

Se pueden crear modelos reales en función de los requisitos de semiconductores, Modelos de ingeniería y otros equipos experimentales, Trabajamos con universidades de todo el mundo.