In today’s high-speed operation of innovation and iteration, when you hold breakthrough product design drawings or face the dilemma of accidental damage to key parts of equipment, whether you can quickly and accurately convert them into physical objects often determines the success or failure of the project. That’s where CNC machining services are your indispensable precision manufacturing magicians.

CNC Machining: The Cornerstone of Precision for Intricate Custom Parts

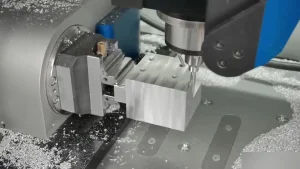

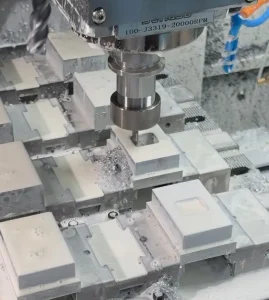

The core charm of CNC (Computer Numerical Control) machining lies in its unparalleled precision and flexibility. A high-performance machine with multi-axis linkage is controlled by pre-programmed digital commands, which can “engrave” extremely complex geometries from robust metal blocks (e.g. aluminum, stainless steel, titanium) or engineering plastics. Whether it’s a custom part with stringent weight and strength requirements in the aerospace field, or a functional implant prototype in a medical device that must perfectly match the human body’s structure, CNC machining can be achieved with ultra-high precision down to the micron level, typically up to ±0.005mm or more). This “subtractive material” process ensures excellent structural strength and excellent surface finish of the final part, making it ideal for high-end functional and durable parts.

Rapid Prototyping: From Idea to Accessible Accelerator

In the product development cycle of racing against time, “fast” is the core competitiveness. Modern CNC machining service providers understand this and use rapid prototyping capabilities as a core strength. Through efficient digital process management, optimized machining strategies such as high-speed milling, and agile production scheduling, complex design drawings can be transformed into physical parts that can be tested, validated, or used directly in a fraction of the time, often in just a few days. Engineers can quickly iterate and verify the functionality of designs without waiting long for mold development. Par exemple, an innovative robot joint component may take only 48 hours from design optimization to metal prototype that can be assembled and tested, which greatly reduces the R&D cycle, reduces trial and error costs, and allows innovative ideas to be implemented quickly.

Custom Parts: The Key to Limitless Design Imagination

Unique needs that standard parts can’t solve? This is where custom parts come in. CNC machining is virtually untethered by design complexity. Whether it’s special-shaped surfaces, complex internal cavities, micro-pore arrays, or strict requirements for special material properties (such as high strength, corrosion resistance, and high temperature resistance), professional CNC service providers can faithfully present your unique ideas with their technical accumulation and advanced 5-axis machining capabilities. It unlocks infinite possibilities for designers, allowing wild ideas to be no longer limited by the manufacturing process and truly achieve “what you think is what you get”.

Epilogue

CNC machining services, a perfect blend of precision manufacturing, deep customization, and quick response. It is not only a reliable manufacturer of complex, high-precision custom parts, but also a powerful engine that drives rapid prototyping and iteration of products. In the modern manufacturing industry, where innovation, efficiency, and quality are pursued, choosing a professional CNC machining partner means you hold the key to transforming design excellence into market success. And when you need to bring your unique ideas to life with speed and precision, don’t forget this magician in precision manufacturing – it’s always ready to let your ideas know no bounds. Contact a professional service provider today and start your customized precision manufacturing journey!