הדפסת תלת מימד מפלסטיק

לְשָׁרֵת

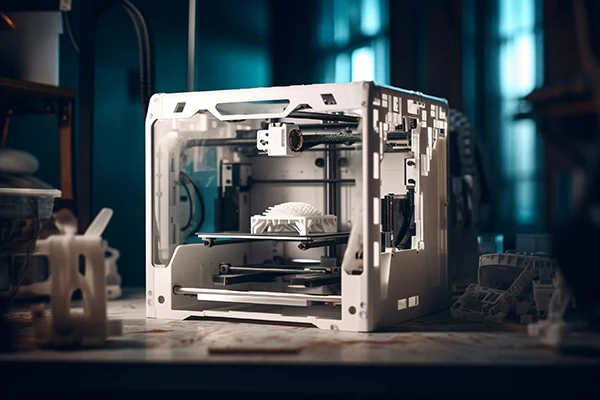

Plastic 3D printing is an additive manufacturing technology that creates three-dimensional objects by building up materials layer by layer.

One-off CNC machining prototype

Our plastic 3D printing capabilities

There are many advantages to choosing Rapidefficient plastic 3D printing. רֵאשִׁית, It enables highly complex plastic part designs, Easily create shapes that are difficult to create with traditional techniques, Meet individual needs. שֵׁנִית, rapid prototyping, Greatly shorten product development cycle, Reduce time costs, Enable enterprises to respond to market changes faster. Furthermore, Can be customized as needed, Small batch production is also cost-effective, No need for expensive molds. in addition, Able to flexibly choose a variety of plastic materials, Adapt to the performance requirements of different application scenarios. You can also adjust the design in real time, Reduce error costs. In short, Rapidefficient plastic 3D printing supports innovation and efficient production.

Plastic 3D printing is an additive manufacturing technology, Build three-dimensional objects by stacking plastic materials layer by layer.

It utilizes 3D printing equipment, plastic materials such as thermoplastics, Photosensitive resin, וכו', with filaments, Powder or liquid form, According to the pre-designed digital model, Point by point from bottom to top, line by line, Stacking face by face, Finally form the required plastic products.

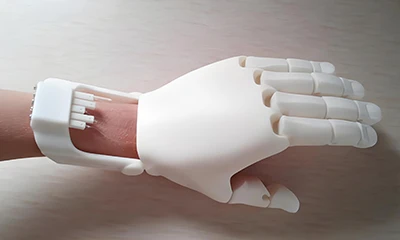

Plastic 3D printing is highly flexible and customizable, Can produce parts and models of various complex shapes, Widely used in industrial design, prototyping, medical, educate, Art and other fields. לְדוּגמָה, in industrial design, Product prototypes can be quickly produced for testing and optimization; in medical field, Personalized medical devices and implants can be customized.

Industrial Design and Prototyping

Quickly validate product designs:

Designers can turn ideas into physical models in a short time, לְדוּגמָה, the casing of new electronic products, Rapidly create prototypes with 3D printing, to verify its size, Appearance and fitability, Compared with traditional mold making and prototyping, Time is greatly shortened, The cost is also lower.

Ability to quickly make multiple iterations of design modifications, Quickly reprint the model for testing after each modification, Improve design perfection.

Medical field

Customized medical devices:

Customized and personalized prosthetics, Orthotics and other rehabilitation aids, Precisely designed and 3D printed based on patient’s physical characteristics and needs, Make the device fit perfectly to the patient’s body, Improve patient comfort and effectiveness.

Print customized dental models, dental crown, dental bridge etc., Meet the unique shape and size requirements of different patients’ mouths, Compared with traditional handmade, Higher accuracy, Shorter production cycle.

Automotive industry

Customization of interior and exterior parts:

Can be based on customers’ individual needs, Parts for custom car interiors, Such as center console decorative parts, door handle, Shift lever etc., Achieve unique interior decoration effects, Improving car personalization.

Quickly create customized kits for car appearance, like car body surround, Air intake grille, וכו', For design display of car modifications or concept cars, Able to see the actual modification effect in a short time.

Education field

Teaching model production:

For science and engineering courses such as physics, Chemical, Making teaching models for biology, וכו', such as molecular structure model, human organ model、Mechanical transmission model, וכו', Help students understand abstract knowledge concepts more intuitively

Creative sculpture models can be printed in art education, Allow students to create art and design in three-dimensional space, Cultivate students’ spatial imagination and creativity.

Architectural design field

Architectural model making:

Architects can quickly print out scale models of buildings, Used to display design proposals, including the exterior of the building, Internal space layout, וכו', Convenience to customers, Construction team communicates and exchanges.

Ability to create models of complex building structures,like a strange building, Large complexes, וכו', Better present the uniqueness and innovation of design, Help assess building feasibility and visual impact.

Consumer goods field

Creative homeware design:

Design and print unique and creative homewares, such as lamps, vase, tableware, Decorations etc., Meet consumers’ needs for personalized home decoration, Add a unique artistic atmosphere to your home environment

Leverage the flexibility of 3D printing, Create multifunctional homewares, Such as furniture parts that can be deformed or combined, Improve the utilization and fun of home space.

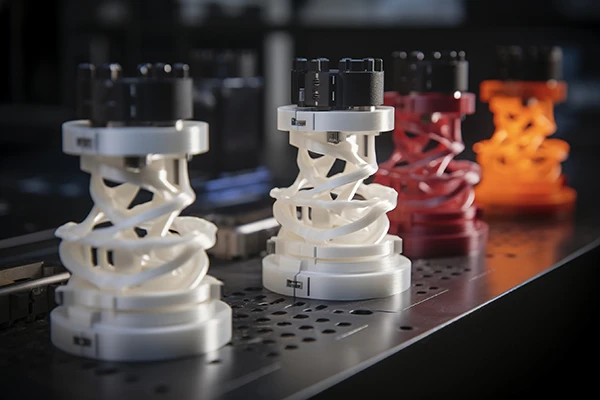

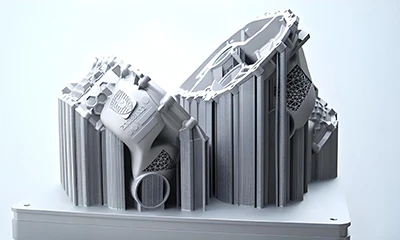

In the plastic 3D printed parts display area, Various wonderful works are eye-catching. There are exquisite and small mechanical parts, Demonstrating the charm of high-precision printing, Can be used for prototype development and low-volume production. There are also creative art ornaments, Unique shapes and delicate textures highlight the endless possibilities of plastic 3D printing. Customized models in the medical field, such as prosthetics and dental models, Highlights the advantages of its personalized services. From industrial design to home decoration, These parts cover a variety of areas, Demonstrating the flexibility of plastic 3D printing, Efficient and innovative, Bring new opportunities and breakthroughs to the development of various industries.

1. Complex shape design: Plastic 3D printing enables complex geometries to be easily realized, This is beyond the reach of traditional manufacturing methods. Whether it has complex cavities inside, Fine hollow structure, Or parts with unique curved surfaces and shaped contours, can be precisely manufactured using 3D printing technology. לְדוּגמָה, in medical field, Personalized prostheses can be printed based on the patient’s specific anatomy, Dental braces, etc.

2. Personalized customization: One-on-one customized production can be carried out according to the specific needs of customers. Whether it is a unique art design, Personalized electronic product housings, Or industrial parts with specific functional requirements, can be quickly customized by adjusting design parameters. for example, Some designers can use plastic 3D printing technology to turn their ideas into reality, Create unique fashion accessories or home decorations.

1. Rich selection of plastic materials: at present, A wide range of plastic materials available for 3D printing, including engineering plastics, flexible plastic, High temperature resistant plastics, וכו', Different materials have different performance characteristics, Can meet application needs in different fields. לְדוּגמָה, Engineering plastics have high strength and stiffness, Suitable for manufacturing mechanical parts; Flexible plastics can be used to make wearable devices and soft products.

2. Performance can be adjusted: By adjusting printing parameters and post-processing processes, The performance of plastic 3D printed parts can be controlled to a certain extent. לְדוּגמָה, Print layer thickness can be changed, Fill density and other parameters to adjust the strength and weight of the part; through post-processing processes such as annealing, Chemical treatment, וכו', Can improve the surface quality and mechanical properties of parts. באותו זמן, Multiple materials can also be combined for composite printing, Optimized combinations for performance.

1. Shorten development cycle: during product development, Plastic 3D printing enables rapid prototyping, Allows designers and engineers to evaluate and improve products in a short period of time. Compared with traditional mold manufacturing, Greatly save time and cost. לְדוּגמָה, in the automotive industry, Component development for new car models can be quickly prototyped through 3D printing, Perform performance testing and optimization, Thereby accelerating the development progress of the entire model.

2. Efficient small batch production: For small batch production needs, Plastic 3D printing has clear advantages. No need to make expensive molds, Can be produced directly based on digital models, Respond quickly to market needs. לְדוּגמָה, Some emerging electronics companies can use 3D printing technology to quickly produce small batches of special parts, Meet early marketing and customer trial needs.

Determine needs

1. Identify the purpose of the plastic part to be printed, size, Accuracy requirements, וכו', לְדוּגמָה, If it is used for industrial prototyping, May require higher accuracy and strength; If it is a creative jewelry, pay more attention to appearance design

2. Consider required material properties, Different plastic materials have different hardnesses, toughness, Heat resistance, etc.

Design model

1. Design part models using professional 3D modeling software, Make sure the model is well structured, No errors. You can refer to existing design cases or make innovative designs based on actual needs.

2. Pay attention to the process characteristics of 3D printing when designing, Such as avoiding too small structures, Design appropriate supports, etc.

Choose equipment and materials

1. Choose the right 3D printer based on your part’s requirements and budget. Desktop and industrial grade printers available, Industrial grade usually has higher accuracy, Larger print size.

2. Choose the right plastic material, Such as ABS, PLA, TPU etc., Each material has its own unique performance characteristics.

Print settings

1. Import the designed model into the 3D printer software, Set printing parameters, including layer thickness, Printing speed, Temperature etc.

2. Place the printing platform, Make sure the platform is level, to ensure print quality.

Start printing

1. Start the printer, Observe the printing process, Make sure printing is working properly. if something goes wrong, Pause printing and make adjustments promptly.

2. After printing is completed, Carefully remove parts, Remove support structures (if any).

Post-processing

1. Polish the parts, Polishing and other treatments, to improve surface quality.

2. Color as needed, Coating and other treatments, Enhance part aesthetics and performance.

בין אם אתה צריך מספר קטן של חלקים או 10000 אובייקטי ייצור מרובים שבסופו של דבר נכנסים לשימוש, עיבוד CNC הוא שיטת ייצור אידיאלית. להלן שירותי CNC המותאמים אישית שאנו משיקים.

מאת Rapidefficient, אתה יכול להשלים את ייצור המוצר תוך זמן קצר, כדי להיות מסוגל להיכנס במהירות לשוק.

ייצור תבניות יעיל היא דרך חסכונית, מסוגל לגשר על הפער בין ייצור מדגם לייצור המוני. תן במהירות למוצרים שלך לכבוש את השוק.

לפרויקטים מותאמים אישית, הצוות המקצועי שלנו יעזור לכם להשיג את המוצרים הטובים ביותר מבחינת איכות ויעילות.

כל המידע והחומרים המועלים מאובטחים וסודיים.

The printed surface is rough

Performance: The surface of printed plastic parts is not smooth, There is obvious layering or graininess.

reason: The print layer thickness setting is too large, Printing speed is too fast, The nozzle temperature is inappropriate, Poor material quality etc.

פִּתָרוֹן

Reduce print layer thickness, Improve printing accuracy.

Reduce printing speed, Give materials enough time to blend.

Adjust the nozzle temperature, Ensure the material is fully melted and bonded.

Choose better quality plastic materials.

The print is not strong enough

Performance: Plastic printed parts are prone to breakage or deformation, Unable to withstand certain external forces

reason: Improper material selection, The printing parameters are unreasonable, Unreasonable part structure design, etc.

פִּתָרוֹן

Choose stronger plastic materials, Such as engineering plastics.

Optimize printing parameters, If increasing filling density, Reduce printing speed, etc.

Improve part structure design, Add reinforcement and other structures.

Jam occurs during printing

Performance: 3D The printer’s nozzle is clogged, Causes printing to be interrupted or print quality to deteriorate.

reason: Too much material impurities, The nozzle temperature is too high or too low, Printing speed is too fast, etc.

פִּתָרוֹן

Use better quality plastic materials, Reduce impurities.

Adjust the nozzle temperature, Ensure materials can be melted and extruded smoothly.

Reduce printing speed, Avoid material accumulation at the nozzle.

Print size deviation

Performance: The printed part size does not match the design size, There is a large error.

reason: Printer accuracy problem, Material shrinkage is large, Printing parameter setting errors, etc.

פִּתָרוֹן

Calibrating 3D Printer Accuracy, Make sure the print size is accurate.

Consider material shrinkage, Compensate for dimensions during design.

Check printing parameter settings, Make sure it’s correct.

Print warped

Performance: Printed parts are warped during or after printing, Affect usage.

reason: Printing platform temperature is uneven, Material shrinkage is large, Printing speed is too fast, etc.

פִּתָרוֹן

Ensure the printing platform temperature is even, You can use methods such as a heated bed or applying tape to the platform

Choose plastic materials with smaller shrinkage rates.

Reduce printing speed, Allow material enough time to cool and solidify.

שירותי עיבוד ה-CNC שלנו זכו לשבחים מלקוחות גלובליים מתחומים שונים。אנו מספקים רכיבי עיבוד CNC למגוון תעשיות,מכסה את הדברים הבאים ועוד

חלקים בגודל גדול, כגון פגושי ABS בעיבוד CNC, לוחות מחשב/ABS וחלקי רכב מדויקים, רפלקטור למשל, עֲדָשָׁה, מכלול הגה, מָנוֹעַ, הפצה.

חלקי רובוט לתעשיית הרובוטיקה והאוטומציה, מַפעִיל, גורם קצה, מָנוֹעַ, ציוד בקרה אוטומטי, מתקנים וביתונים.

פלדת עצם מנירוסטה או טיטניום, תוֹתֶבֶת, ציוד נשימה, מכשיר כף יד, ציוד אבחון, מודל אנטומי, רכיבים לצרכים רפואיים כגון מכשירים כירורגיים.

מנוע אירו, גוּף, טוּרבִּינָה, בֶּלֶם, חלקי צמיגים, מערכת תאורה, חלקי משאבת ואקום ומשאבת דלק.

מוצרי צריכה, כגון מארזי ציוד אלקטרוני, לַחְצָן, יָדִית, כַּפתוֹר, מֶתֶג, מכשירים דיגיטליים לבישים, מוצרי בישול, ציוד ספורט.

רכיבים חדשים בתעשיית האנרגיה, לְמָשָׁל. מחליף חום, שַׁסתוֹם, צינור, משאבות ואביזרים, רכיבים הידראוליים, רכיבי סוללה, רכיבי פאנל סולארי, מסגרת ואימפלר.

דיור אלקטרוני, מסוע, אֶטֶב, מַחבֵּר, רכיבי גנרטור, מתקנים, חלקי מכונות וכלי עבודה למכונות תעשייתיות.

ניתן ליצור מודלים בפועל בהתבסס על דרישות מוליכים למחצה, מודלים הנדסיים וציוד ניסיוני אחר, אנו עובדים עם אוניברסיטאות ברחבי העולם.