Techniques and Methods for Effectively Improving the Qualification Rate of Precision Aluminum Extrusion Parts

Industrial aluminum extrusions are now widely used in a wide range of applications, such as in household doors and windows,...

Five Key Factors to Consider When Choosing a CNC Machining Center

CNC machining centers are more expensive than other metalworking equipment and are therefore subject to certain constraints. Choosing the right...

What are the differences between 3-axis, 4-axis, and 5-axis CNC machining?

In the field of CNC machining, we often hear terms like 3-axis, 4-axis, and 5-axis machining. These terms sound impressive,...

CNC machining services: Rapidefficient creates a “fast, accurate, and stable” manufacturing legend

In the arena of manufacturing, CNC machining services have long transcended the mere “part making.” it’s a precision symphony that...

How is CNC Machining Cost Calculated? What Factors Influence It?

CNC machining is a mainstream technology in the manufacturing industry. Due to its high efficiency and precision, many factories and...

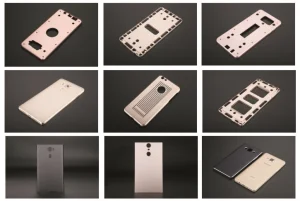

CNC Machining for High-Gloss Mirror Finishes

Introduction CNC machining can directly achieve a high-gloss mirror finish.Currently, high-gloss CNC machining has become increasingly common, especially in the...

Can CNC machining centers process aluminum nitride ceramics?

Aluminum nitride ceramics are a material with excellent thermal conductivity, and their application range is gradually increasing. Although aluminum nitride...

Differences between CNC Machining and 3D Printing

With technological advancements and revolutions in engineering and machinery, you want to know you’re using the best equipment to advance...

What are the common types of CNC machining centers?

CNC machining centers are an upgraded derivative of CNC milling machines. Currently, they come in a variety of forms. RapidEfficient...

The “Invisible Champion” of Precision Instrument Manufacturing: How Rapidefficient Empowers Cutting-Edge Technology with CNC Machining Services

In the world of precision instruments, even the slightest difference can be a thousand miles. From scalpels that manipulate cells...

CNC Machining Services: The “Life Guardians” of Medical Device Precision Manufacturing

Surgical robots that move precisely under shadowless lights, microscopic catheters that travel through blood vessels, orthopedic implants that silently support...

Key Advantages of CNC Swiss-type Machining

CNC Swiss-type machining centers, a sliding headstock automatic lathe that has become increasingly popular in recent years, offer versatile capabilities,...

How can precision parts processing manufacturers improve production efficiency

Introduction In the highly competitive field of precision parts processing, precision parts processing manufacturers are constantly seeking ways to enhance...

Precision Parts Processing Fixture Regulations

Introduction In the realm of CNC machining, precision parts processing fixtures play a pivotal role. They are the unsung heroes...

Custom precision CNC machine tools for plastic automotive parts

Introduction In the automotive industry, plastic parts play a crucial role in modern vehicle manufacturing. They are used in various...

Can we provide customized parts processing service?

Introduction In the dynamic realm of modern manufacturing, the demand for precision and uniqueness has propelled customized parts processing services...

5 Ways to Improve the Accuracy of Precision Parts Processing

Introduction In the manufacturing industry, the accuracy of precision parts processing is of utmost importance. Precision parts are used in...

Theory of precision machining technology

In modern manufacturing, precision machining technology has emerged as a cornerstone, playing a pivotal role in elevating product quality, enhancing...

How to choose five – כלי מכונת ציר?

Introduction In the modern manufacturing landscape, the five – axis machine tool has emerged as a cornerstone of precision and...

Practice and optimization of CNC machining technology

I. Introduction In the modern manufacturing landscape, CNC machining technology stands as a cornerstone. It has revolutionized the way we...

How does die casting meet the needs of complex geometrics?

1. Introduction Die casting is a manufacturing process that has been around for centuries, but it continues to evolve and...

Precision CNC Machining Technology to Create High Quality Parts

Introduction In the modern manufacturing landscape, precision CNC machining technology stands as a cornerstone for creating high-quality parts. It has...

Production technology of NC machining parts in Chinese hardware industry is analyzed

I. Introduction In today’s highly developed manufacturing industry, the Chinese hardware industry plays a crucial role. As an important part...

Common Cold Processing in Machining: Unveiling Efficiency and Precision

I. Introduction Cold working in machining refers to the process of shaping and finishing metal components at or near room...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. אוּלָם, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

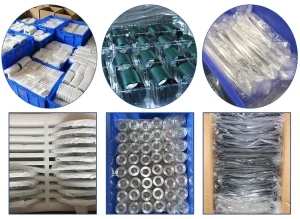

Packaging and Shipping Strategies for Safe Transportation of CNC Machined Parts

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...