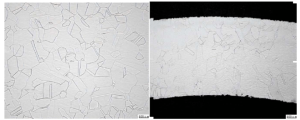

What is the difference between high carbon steel SK2, SK4, SK5, SK7, וכו'?

1. Introduction 1.1 Hook the reader When it comes to choosing the right high carbon steel for your project, are...

What is the difference between 304 and 316 stainless steel?

Stainless steel is widely used in various industries due to its excellent corrosion resistance and durability. Among the many types...

What are the advantages of titanium alloy compared with traditional metal materials?

Titanium alloy has emerged as a remarkable material in the field of engineering and manufacturing, offering several distinct advantages over...

How are tolerances created in machining?

the foundation for tolerances is laid. Engineers and designers use computer-aided design (CAD) software to create detailed 3D models of...

10 Application Areas of 3D Printing

3D printing technology has revolutionized various industries with its unique capabilities and advantages. Here are 10 application areas where 3D...

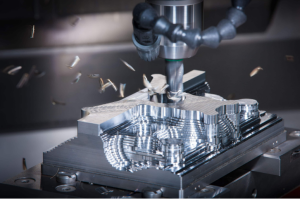

In CNC machining, what are the differences between 3-axis, 4-axis, 5-axis, machining center, turn-milling compound?

Introduction CNC (Computer Numerical Control) machining has revolutionized the field of modern manufacturing. It involves the use of computerized controls...

5 3D Printing Materials Commonly Used in the Medical Industry

Introduction 3D printing, also known as additive manufacturing, has emerged as a revolutionary technology with significant implications in the medical...

Application of 4 Surface Finishing Techniques in Orthopedic Medical Industry

Introduction The Significance of Surface Finishing in Orthopedics In the orthopedic medical industry, the significance of 4 Surface Finishing Techniques...

Material comparison: The difference between high-speed steel and tungsten steel

1、Introduction to High-Speed Steel and Tungsten Steel High-speed steel and tungsten steel are both crucial materials in the field of...

Nine Key Points of CNC Parts Processing

1、Introduction to CNC Parts Processing CNC parts processing, which stands for Computer Numerical Control parts processing, is a revolutionary manufacturing...

Positioning Method of Machining: Unlocking the CNC Potential

I. Introduction What is Machining Positioning Method? Machining positioning method refers to the techniques and approaches used to precisely determine...

304 stainless steel surface treatment process

I. Introduction A. Hook the readers with the importance of 304 stainless steel surface treatment 304 stainless steel is widely...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

CNC Milling Machine: Ideal for Processing Which Parts?

I. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

I. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

I. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

I. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

I. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

Precision Manufacturing, Protecting Lives: CNC Machining is the core solution in the field of medical devices

Under the shadowless light, the titanium alloy orthopedic implant in the surgeon’s hand is accurately fitting the patient’s bone; In...

Rapidefficient: Your expert in CNC machining service solutions

In the modern manufacturing battlefield that pursues efficiency and precision, the precision parts behind every product are the silent declaration...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. אוּלָם, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...