What are the precision machining processes for different types of copper materials?

Common copper materials include: פְּלִיז (an alloy composed of copper and zinc), cupronickel (an alloy composed of copper and nickel),...

Aluminum CNC Lathe Processing Process

Aluminum CNC lathe processing is a highly precise and widely used manufacturing method in modern industry. It combines advanced machining...

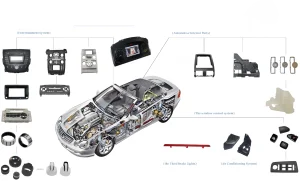

An Inventory of Precision Automotive Parts Processing

Every car is made up of thousands of precision parts, each serving a unique function. With over a century of...

Solutions for the Difficulty of Machining Stainless Steel Parts

עיבוד שבבי, as we commonly refer to it, involves using a cutting tool to remove excess material from a blank or...

Is CNC machining precision stainless steel parts really that difficult?

Common stainless steel precision parts are typically manufactured using standard grades such as 303, 304, 316, and 420. Stainless steel...

When Precision Meets the Sky: The Rigorous Art of CNC Machining in Aerospace

A modern airliner has millions of parts, and many of its key components, from engine turbine blades to landing gear...

CNC Machining Services: Precision Manufacturing Codes Beyond “OEM”

When you hand over a precision part drawing to a CNC machining service provider, do you expect them to just...

Materials and Main Accessories Used in Valve Precision Parts Processing

1. Main Accessories of Valves 2. Valve Body Materials Valve body materials should be selected according to pressure, temperature, corrosion...

What is boring on a CNC machining center? What are its benefits and challenges?

Boring refers to the process of enlarging or refining an existing hole in a workpiece. CNC boring is characterized by...

Five-Axis Machining: A precision manufacturing tool that pushes the limits of traditional CNC machining

In the arena of modern manufacturing, CNC machining services have long been a cornerstone of precision parts manufacturing. אוּלָם, as...

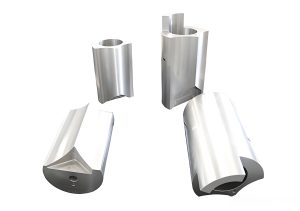

What Are the Product Areas for Each Grade of 6-Series Aluminum Extrusion?

We all know that aluminum extrusions are widely used in a wide range of applications. The primary element of the...

What Factors Influence the Price of Precision-Machined Aluminum Extrusion Parts?

Aluminum extrusions are widely used across industries, but their prices vary significantly. Whether you’re a manufacturer or a user, understanding...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Processing technology of shaft parts

Shaft parts are essential components in numerous mechanical and industrial applications. Their proper processing is crucial to ensure the smooth...

The role of nickel plating on aluminum alloy

Aluminum alloy is a widely used material in various industries due to its excellent properties such as lightweight, good conductivity,...

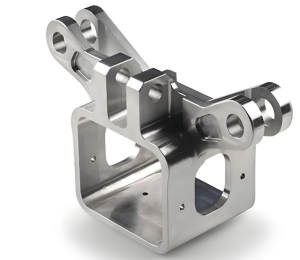

Advantages and disadvantages of CNC machining hardware parts

In the modern manufacturing industry, CNC machining has become a crucial process for producing high-quality hardware parts. CNC (Computer Numerical...

How to improve UAV parts processing efficiency and reduce waste

In today’s rapidly evolving technological landscape, unmanned aerial vehicles (UAVs) have become increasingly popular in various fields such as surveillance,...

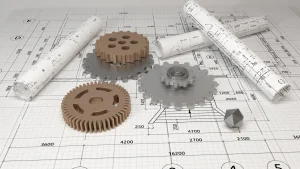

Precision machining technology and process for mold parts

In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in...

Sheet metal stamping technology and application

Sheet metal stamping technology is a crucial manufacturing process that has been widely used in various industries. In this article,...

Challenges and Advances in Irregularly Shaped Parts Processing

Introduction The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts...

6 Essential Knowledge Points for Stainless Steel Machining

Introduction: Stainless steel machining is a critical process in many industries, from aerospace to medical devices. Its high strength, durability,...

Detailed explanation of CNC machining accuracy

1. Introduction to CNC Machining Accuracy CNC (Computer Numerical Control) machining has become one of the most crucial methods of...

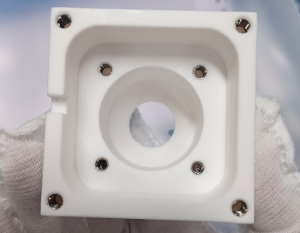

Applications of Teflon Materials in the Machining Industry

Introduction: טפלון, a brand name for polytetrafluoroethylene (PTFE), has gained widespread popularity in the machining industry due to its exceptional...

Rapidefficient: Your expert in CNC machining service solutions

In the modern manufacturing battlefield that pursues efficiency and precision, the precision parts behind every product are the silent declaration...

The Duo of Speed and Precision: The Winning Way to Choose a CNC Machining Service Provider

In today’s rapid-paced manufacturing arena, “time is money” is no empty phrase. Production line shutdown due to delays in critical...

How Rapid Efficient Pushes CNC Machining Services to New Heights of Efficiency

In today’s competitive manufacturing landscape, precision and efficiency are the lifeblood of survival. Enterprises are not only looking for qualified...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. אוּלָם, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

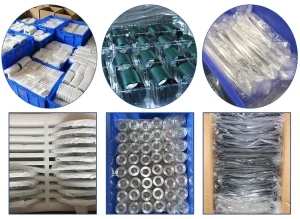

Packaging and Shipping Strategies for Safe Transportation of CNC Machined Parts

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...