Chatter Marks in CNC Machining and Solutions

Chatter marks in CNC machining are often caused by a variety of factors. Here are some possible solutions: CNC Machining...

Common Troubleshooting Methods for Stainless Steel Part Processing

Stainless steel part processing involves the fabrication of functional parts from stainless steel sheet metal using a variety of cold...

How to control costs and production management in non-standard hardware parts processing?

Non-standard hardware parts processing refers to hardware custom-made to specific customer requirements (such as non-standard size, shape, or function) that...

Let’s Learn About the Advantages of CNC Milling and Turning

CNC milling and turning is an advanced CNC machining technology that integrates multiple machining functions, including turning, milling, drilling, and...

What are the key points for quality control in stainless steel part processing?

Stainless steel part processing refers to the process of transforming raw materials (such as stainless steel plates, bars, pipes, and...

How to reduce part breakage during machining while maintaining dimensional accuracy?

In component manufacturing, dimensional accuracy and breakage risk are often intertwined. The higher the dimensional accuracy requirements, the more complex...

What are the typical applications of CNC 4-axis machining?

CNC 4-axis machining is a CNC machining method that adds a rotary axis (usually the A or B axis) to...

How to remove knife marks produced during stainless steel machining?

Knife marks (cutting marks) produced during stainless steel machining are surface defects caused by friction between the tool and the...

How can we ensure quality when processing non-standard hardware parts?

The processing quality of non-standard hardware parts (metal parts with non-standard specifications and customized to specific needs) directly impacts equipment...

What factors affect the cost of parts processing?

The cost of parts processing is affected by many factors, from material selection to post-processing and testing. Differences in each...

What are the accuracy and quality inspection requirements after CNC machining?

The accuracy and quality of CNC machining directly determine the assembly performance and reliability of the workpiece. After machining, systematic...

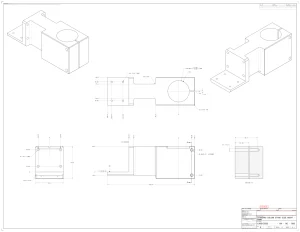

Analysis of the process flow of CNC machining parts

CNC machining is a process that uses computer programming to control machine tools for precision machining. The process flow of...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

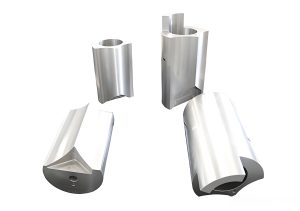

Processing technology of shaft parts

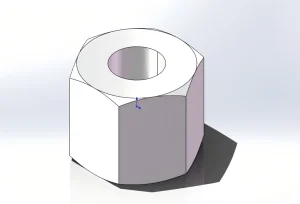

Shaft parts are essential components in numerous mechanical and industrial applications. Their proper processing is crucial to ensure the smooth...

The role of nickel plating on aluminum alloy

Aluminum alloy is a widely used material in various industries due to its excellent properties such as lightweight, good conductivity,...

Advantages and disadvantages of CNC machining hardware parts

In the modern manufacturing industry, CNC machining has become a crucial process for producing high-quality hardware parts. CNC (Computer Numerical...

How to improve UAV parts processing efficiency and reduce waste

In today’s rapidly evolving technological landscape, unmanned aerial vehicles (UAVs) have become increasingly popular in various fields such as surveillance,...

Precision machining technology and process for mold parts

In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in...

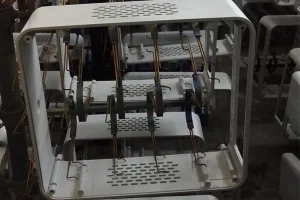

Sheet metal stamping technology and application

Sheet metal stamping technology is a crucial manufacturing process that has been widely used in various industries. In this article,...

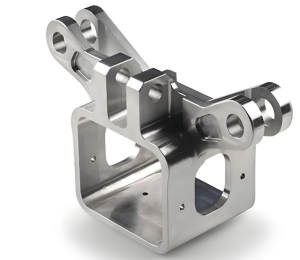

Challenges and Advances in Irregularly Shaped Parts Processing

Introduction The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts...

6 Essential Knowledge Points for Stainless Steel Machining

Introduction: Stainless steel machining is a critical process in many industries, from aerospace to medical devices. Its high strength, durability,...

Detailed explanation of CNC machining accuracy

1. Introduction to CNC Machining Accuracy CNC (Computer Numerical Control) machining has become one of the most crucial methods of...

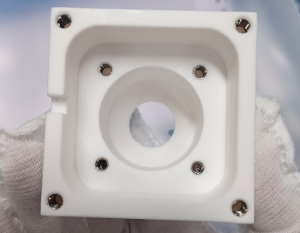

Applications of Teflon Materials in the Machining Industry

Introduction: טפלון, a brand name for polytetrafluoroethylene (PTFE), has gained widespread popularity in the machining industry due to its exceptional...

Aluminum CNC Prototyping: Revolutionizing Product Development with Rapidefficient

1. Introduction In the highly competitive landscape of modern manufacturing, Aluminum CNC prototyping has emerged as a cornerstone for innovation...

Unleashing the Power of CNC Aluminum Parts Manufacturing with Rapidefficient

1、Introduction In today’s rapidly evolving industrial landscape, CNC aluminum parts manufacturing plays a crucial role. This article aims to provide...

CNC Aluminum Machining Services: Unleashing Precision and Efficiency

Introduction Overview of CNC Aluminum Machining CNC aluminum machining is a highly sophisticated and essential process in various industries. This...

High-Precision Aluminum CNC Machining: A Comprehensive Overview

1、Introduction to High-Precision Aluminum CNC Machining High-precision aluminum CNC machining is a crucial process in modern manufacturing. It involves the...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

I. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

High-Precision Multi-Hole Flange Connection Plate

I. Choosing the Right Material Eliminates the Risk of Later Defects For this component, we initially had two material options...

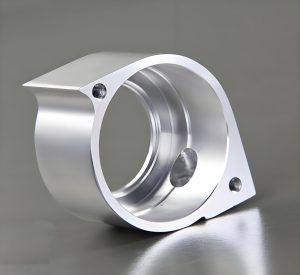

Aluminum alloy precision valve body

1、 Choosing the right materials saves 80% of the trouble in the later stage We use 6061-T6 aluminum alloy (compliant...

Stainless steel porous precision mechanical sleeve:the “sturdy protective umbrella” of equipment.

Introduction In industrial equipment, if there is a component that can be like a “sturdy steel armor”, tightly protecting the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

High – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, and...

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Rapidefficient Customer Collaboration Case Study – O-Net Technologies Group

Rapidefficient Customer Collaboration Case Study: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (שנזן) Group Co., Ltd is a prominent...

Rapidefficient Customer Collaboration Case Study – Shenzhen Colibri Technologies

Rapidefficient Customer Collaboration Case Study: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...