עיבוד חיתוך חוט

לְשָׁרֵת

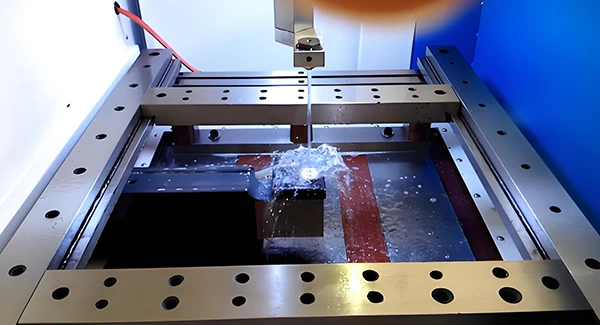

Wire cutting is a processing method that uses the principle of electric spark discharge to cut conductive materials.

One-off CNC machining prototype

Our wire EDM parts capabilities

Choose Rapidefficient Wire EDM, Because of its high precision, Can process complex shapes, fine structure; Wide adaptability to materials, Can process a variety of conductive materials; And it is non-contact processing, Avoid force deformation of workpiece, Can guarantee surface quality, Comprehensive advantages are significant.

Wire cutting is a processing method that uses the principle of electric spark discharge to cut conductive materials. during processing, A thin metal wire (usually molybdenum or brass) as an electrode, Apply pulse voltage between workpiece and wire electrode, spark discharge. The high temperature of the electric spark locally melts and vaporizes the workpiece material, To achieve material cutting.

“Applicable material types

Steel: Including various carbon steels, Alloy steel and stainless steel, וכו', Steel has good mechanical properties and processability, Is one of the most commonly used materials in wire cutting processing. ”

אֲלוּמִינְיוּם: Aluminum and its alloys are lightweight, Good thermal conductivity and other characteristics, Widely used in aerospace, Automobile manufacturing and other fields. Wire-cut machining can easily process various aluminum parts with complex shapes.

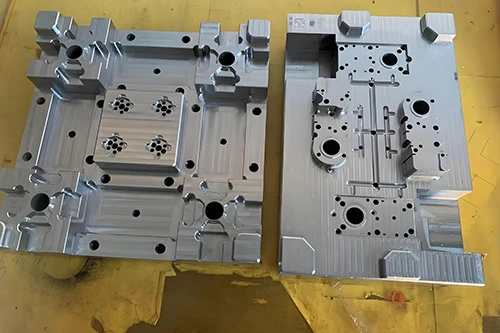

Mold making

Capable of processing complex molds with high precision, Such as injection mold, Stamping die, וכו', Ensure mold accuracy and quality.

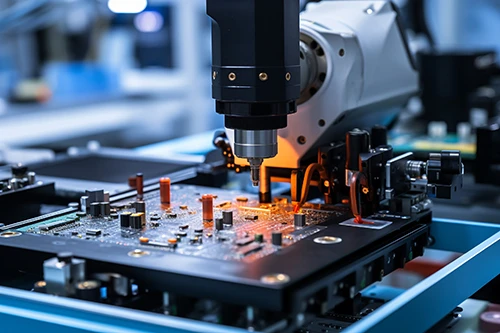

Precision parts

Good at processing electronics, Precision parts in medical and other fields, High dimensional accuracy, Good surface quality.

Special-shaped parts processing

Can process various special-shaped parts, Meet special design needs, High shape accuracy.

Hard material processing

Good processing effect on cemented carbide and other materials, Even parts with high hardness can be handled easily.

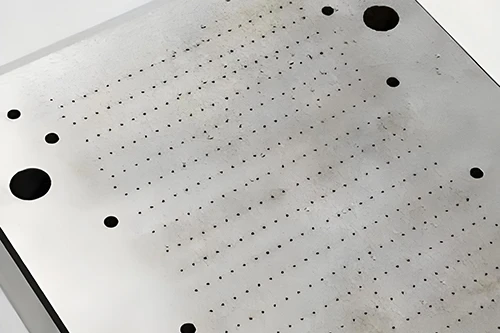

Small hole processing

Micro hole processing possible, High precision, Suitable for precision instruments and other fields.

New product development

Provide rapid development of new products, High-precision sample processing services.

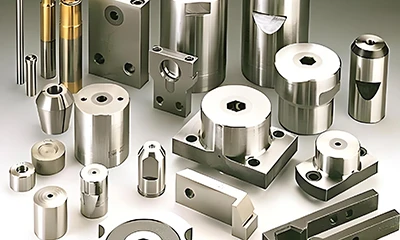

Display of wire cutting parts, High precision, Complex and diverse shapes, Smooth surface, Highlight the charm of advanced processing technology.

Able to achieve micron-level precision processing, Ensure part dimensions are accurate, For demanding applications.

Can process various complex shape parts, Not limited by traditional processing.

Can process a variety of conductive materials, Adaptable.

Understand the wire cutting process

Wire cutting machining uses electric spark discharge between the electrode wire and the workpiece, A processing method that removes workpiece material. Be familiar with its principles, Category (fast wire、Slow moving wire, וכו') and scope of application.

Determine processing needs

Clarify the specific requirements for the parts to be processed, including dimensional accuracy, shape complexity, Surface roughness, וכו', Consider the function of the parts in the product and the environment in which they are used.

Choose the right equipment

Based on part requirements and budget, Choose the right wire cutting equipment. Fast wire-traveling equipment costs less but has slightly lower accuracy, Slow wire moving equipment has high precision but is expensive.

Design and programming

1. When designing parts, Consider the process characteristics of wire cutting processing, Avoid difficult-to-machine structures. Reasonable design of machining allowance, Threading holes, etc.

2. Use professional wire cutting programming software, Convert part design into machining code. Ensure programming accuracy and efficiency.

Process control

1. Install workpiece and electrode wire, Make sure the installation is secure and in the correct position.

2. Set appropriate processing parameters, Such as discharge current, pulse width, Feed speed, וכו', According to material, Thickness and other factors can be adjusted.

3. Monitor the machining process, Pay attention to the wear of the electrode wire, Discharge status, וכו', Adjust parameters or replace electrode wire in time.

Quality inspection

1. Comprehensive quality inspection of finished parts, Includes dimensional measurements, Shape check, Surface roughness testing, etc.

2. Use measuring tools, Microscope and other testing equipment, Ensure parts meet quality standards.

Post-processing

Post-process as needed, Such as deburring, polishing, Cleaning etc., Improve the appearance quality and performance of parts.

Packaging and storage

Use appropriate packaging, Prevent parts from being damaged during shipping and storage. Storage environment should be dry, clean, Avoid parts getting wet, חֲלוּדָה.

בין אם אתה צריך מספר קטן של חלקים או 10000 אובייקטי ייצור מרובים שבסופו של דבר נכנסים לשימוש, עיבוד CNC הוא שיטת ייצור אידיאלית. להלן שירותי CNC המותאמים אישית שאנו משיקים.

מאת Rapidefficient, אתה יכול להשלים את ייצור המוצר תוך זמן קצר, כדי להיות מסוגל להיכנס במהירות לשוק.

ייצור תבניות יעיל היא דרך חסכונית, מסוגל לגשר על הפער בין ייצור מדגם לייצור המוני. תן במהירות למוצרים שלך לכבוש את השוק.

לפרויקטים מותאמים אישית, הצוות המקצועי שלנו יעזור לכם להשיג את המוצרים הטובים ביותר מבחינת איכות ויעילות.

כל המידע והחומרים המועלים מאובטחים וסודיים.

Poor surface roughness: The surface of the processed parts is rough, Unsatisfactory finish

Reason: Discharge parameters are unreasonable, Electrode wire wear, Working fluid pollution, etc.

פִּתָרוֹן

Optimize discharge parameters, Reduce discharge current and pulse width, Increase pulse frequency.

Replace worn electrode wire promptly, Keep the electrode wire in good condition.

Change working fluid regularly, Ensure the cleanliness of the working fluid.

Dimensional deviation: There is a difference between the actual processing size and the design size

Reason: programming error, Machine tool accuracy issues, Electrode wire tension is unstable, etc.

פִּתָרוֹן

Double check programming code, Make sure programming is correct.

Regularly perform accuracy testing and adjustments on machine tools, Ensure the accuracy of machine tools.

Stable electrode wire tension, Use equipment such as tension adjusters.

Disconnected: The electrode wire suddenly broke during processing

Reason: Electrode wire quality issues, Discharge parameters are too large, There are hard points inside the workpiece, etc.

פִּתָרוֹן

Choose good quality electrode wire, Avoid using poor quality electrode wire.

Reduce discharge parameters, Avoid excessive discharge energy causing electrode wire breakage.

Preprocess workpieces, Remove impurities such as hard spots.

Shape error: The shape of the processed parts does not match the designed shape

Reason: programming error, Machine tool accuracy issues, Electrode wire shaking, etc.

פִּתָרוֹן

Double check programming code, Ensure programming is accurate.

Perform accuracy inspection and adjustment on machine tools, Improve the motion accuracy of machine tools.

Take measures to reduce the vibration of the electrode wire, Such as using guide devices, etc.

שירותי עיבוד ה-CNC שלנו זכו לשבחים מלקוחות גלובליים מתחומים שונים, אנו מספקים רכיבי עיבוד CNC למגוון תעשיות, מכסה את הדברים הבאים ועוד.

חלקים בגודל גדול, כגון פגושי ABS בעיבוד CNC, לוחות מחשב/ABS וחלקי רכב מדויקים, רפלקטור למשל, עֲדָשָׁה, מכלול הגה, מָנוֹעַ, הפצה.

חלקי רובוט לתעשיית הרובוטיקה והאוטומציה, מַפעִיל, גורם קצה, מָנוֹעַ, ציוד בקרה אוטומטי, מתקנים וביתונים.

פלדת עצם מנירוסטה או טיטניום, תוֹתֶבֶת, ציוד נשימה, מכשיר כף יד, ציוד אבחון, מודל אנטומי, רכיבים לצרכים רפואיים כגון מכשירים כירורגיים.

מנוע אירו, גוּף, טוּרבִּינָה, בֶּלֶם, חלקי צמיגים, מערכת תאורה, חלקי משאבת ואקום ומשאבת דלק.

מוצרי צריכה, כגון מארזי ציוד אלקטרוני, לַחְצָן, יָדִית, כַּפתוֹר, מֶתֶג, מכשירים דיגיטליים לבישים, מוצרי בישול, ציוד ספורט.

רכיבים חדשים בתעשיית האנרגיה, לְמָשָׁל. מחליף חום, שַׁסתוֹם, צינור, משאבות ואביזרים, רכיבים הידראוליים, רכיבי סוללה, רכיבי פאנל סולארי, מסגרת ואימפלר.

דיור אלקטרוני, מסוע, אֶטֶב, מַחבֵּר, רכיבי גנרטור, מתקנים, חלקי מכונות וכלי עבודה למכונות תעשייתיות.

ניתן ליצור מודלים בפועל בהתבסס על דרישות מוליכים למחצה, מודלים הנדסיים וציוד ניסיוני אחר, אנו עובדים עם אוניברסיטאות ברחבי העולם.