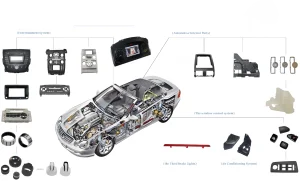

Every car is made up of thousands of precision parts, each serving a unique function. With over a century of automotive history, the manufacturing techniques for these parts have steadily improved. From forming and assembly, cars emerge. Rapido presents four common processes for automotive parts processing.

1. Automotive Parts Casting

Automotive parts casting involves pouring molten metal into a special casting cavity, where it solidifies and takes the approximate shape of the product.

This process is very common in automotive parts manufacturing, with many applications including engines and connecting rods. Many parts in automotive parts manufacturing are made from cast iron. Despite the trend toward lightweighting, cast iron still accounts for about 10% of a vehicle’s weight, including:

- Cylinder blocks

- Transmissions

- Rear axles

- Steering gears

- Various brackets

Casting iron parts are typically made using sand molds, formed from sand mixed with a binder and water. Sand mold material must have sufficient adhesive strength to maintain shape and resist collapse under molten iron impact.

To create a cavity in the sand mold, a pattern (traditionally wood, now often resin or metal) is produced. Since molten iron shrinks as it cools, the pattern is made slightly larger than the final part.

After casting, excess material is removed through CNC machining.

2. Automotive Parts Forging

Forging is another common process in automotive parts manufacturing, divided into open-die forging and closed-die forging.

This process, comparable to traditional “blacksmithing,” is still used in high-strength component production. Automotive forging involves placing a heated metal blank into a mold, then applying impact or pressure to form the desired shape.

Advantages of forging include higher strength and precision. Common forged automotive parts include:

- Engine connecting rods

- Front axles

- Crankshafts

- Steering knuckles

Closed-die forging is particularly precise, where the blank is compressed within a die to form contours similar to shaping dough in a mold.

3. Automotive Parts Cutting

Cutting removes excess material from a blank to achieve the required shape, dimensions, and surface quality. Automotive parts cutting methods include manual cutting (bench work) and MACCHING CNC.

Common machining processes:

- Turning: Performed on CNC lathes, machining outer diameters, inner diameters, and end faces. Used for shafts and gear blanks.

- Milling: Performed on CNC milling machines (now four- and five-axis), capable of machining flat, curved, and complex surfaces, including grooves. Essential for parts and stamping die manufacturing.

- Drilling & Boring: Used to machine precision holes in parts.

- Grinding: Provides superior precision and surface finish, capable of processing hardened or heat-treated materials that are difficult for standard cutting tools.

4. Automotive Parts Stamping

Stamping is used for sheet metal automotive parts, such as:

- Engine pans

- Doors

- Hoods

- Brake system underplates

Typical stamping processes include blanking, punching, stretching, bending, shaping, and trimming.

Stamping requires a die set consisting of an upper die (providing downward force) and a lower die (providing support). The blank is placed between the two dies, and impact force forms the part.

Stamping is highly efficient, suitable for producing complex shapes with high precision. Stamping presses are categorized by tonnage—commonly 40-ton, 60-ton, and 100-ton models—depending on the part’s size and material.

RapidEfficient Expertise

Rapido specializes in high-precision CNC machining with 18 years of experience.

Its products cover industries including:

- Medico

- Communications

- Optics

- Drones

- Intelligent robots

- Automotive

- Office automation

The company’s CNC machining centers include four-axis, five-axis, and multi-linkage machines. Testing and inspection equipment includes:

- Precision projectors

- Coordinate measuring machines (CMMs)

- Spectrometers

Machining accuracy: 0.01 mm

Testing accuracy: 0.001 mm