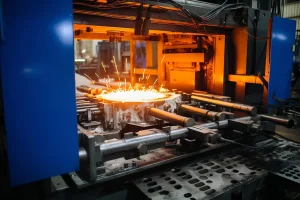

What Plastic Is Used in Injection Molding?

Injection molding is a widely-used process in manufacturing, particularly for creating plastic parts and products. The choice of plastic is...

What Is the Process of Sheet Metal Processing?

Sheet metal processing is a crucial process in manufacturing, where flat metal sheets are transformed into functional parts and products....

Why Is Injection Molding So Popular?

Injection molding is a manufacturing process that has gained widespread popularity in various industries. From creating small, detailed parts to...

What are the 4 types of sheet metal processing operations?

Sheet metal processing plays a crucial role in creating parts and products for various industries. To turn flat metal sheets...

Applications of Overmolding

Overmolding is a versatile manufacturing process. It combines two or more materials into a single part. This technique offers numerous...

Advantages of Overmolding

Overmolding is a unique manufacturing process. It involves combining two or more materials into one product. This technique offers various...

The Difference Between Injection Molding and Overmolding

Injection molding and overmolding are both crucial manufacturing processes. While they share some similarities, they have distinct characteristics. Understanding these...

What is Overmolding?

Overmolding is a specialized injection molding process. It involves combining two or more materials to create a single, finished part....

What is Injection Molding?

Injection molding is a manufacturing process used to create plastic parts. It involves injecting molten plastic into a mold. This...

The Basic Process of Sheet Metal Processing

Sheet metal processing plays a crucial role in many industries, including automotive, aerospace, construction, and electronics. This process involves transforming...

Trends in the Development of Sheet Metal Processing

Sheet metal processing continues to evolve as technology advances. This process is essential across various industries, including automotive, aerospace, construction,...

Applications of Sheet Metal Processing

Sheet metal processing is a crucial process used across a variety of industries. Its versatility, precision, and durability make it...

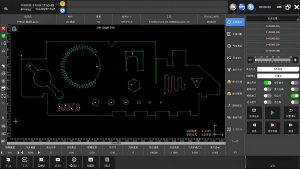

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

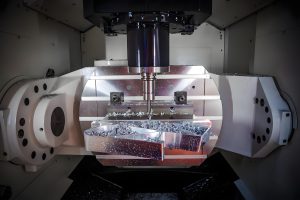

Heat Treatment of CNC Machined Parts

I. Introduction In recent years, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

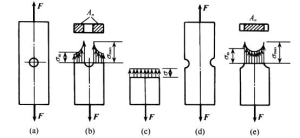

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

What common materials are suitable for making gears?

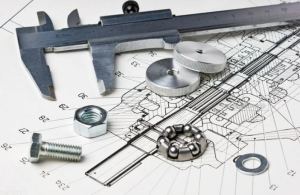

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

New energy parts CNC machining fast solution

I. Introduction In recent years, with the rapid development of new energy technologies, the demand for new energy parts has...

Fast solution for cnc machining medical parts

1. Introduction In recent years, the medical industry has witnessed remarkable growth, with a surging demand for sophisticated and precise...

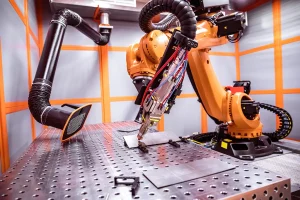

Robot parts CNC machining fast solution

Ⅰ. Introduction In recent years, the field of robotics has witnessed remarkable advancements, revolutionizing industries across the globe. From automotive...

CNC Machining Technology of Thin-Walled Shell Parts with Easy Deformation: High-Speed Solutions

I. Introduction Thin-walled shell parts,with their lightweight and compact design, have become ubiquitous in various industries. From aerospace components that...

Application of high speed CNC machining in aircraft parts manufacturing

I. Introduction In the highly advanced realm of aircraft manufacturing, precision and efficiency are not just desirable traits but absolute...

Overview: Types of Springs and their applications

Springs: An Introduction Springs are ubiquitous mechanical components that play a crucial role in modern life. They are elastic objects...

Parts processing technology and flow

The Core of Parts Processing Technology What is Parts Processing Technology Parts processing technology is the cornerstone of modern manufacturing,...

CNC Machining of Aluminum Alloy Material

The Basics of Aluminum Alloy in CNC Machining What is Aluminum Alloy? Aluminum alloy is a material composed mainly of...

Three Factors Affecting the Machining Accuracy of CNC Milling Machine and Four Solutions

1、Introduction to CNC Milling Machine Machining Accuracy 1. Briefly introduce what CNC milling machine machining accuracy means and its importance...

CNC solutions from Rapidefficient suppliers

In the ever-evolving landscape of manufacturing, precision and efficiency are paramount. This is where CNC (Computer Numerical Control) solutions come...

Explore Precision with Aerospace CNC Machining Solutions

Introduction Aerospace CNC machining is a critical aspect of the modern aerospace industry. This blog will explore the world of...

Rapid and Efficient Precision Machining and Manufacturing: A Comprehensive Review

ABSTRACT This paper explores the significance of rapid and efficient precision machining and manufacturing. It elaborates on the crucial role...

Case study di collaborazione per clienti rapide. – Gruppo O-Net Technologies

Case study di collaborazione per clienti rapide.: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Case study di collaborazione per clienti rapide. – Shenzhen Colibri Technologies

Case study di collaborazione per clienti rapide.: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...