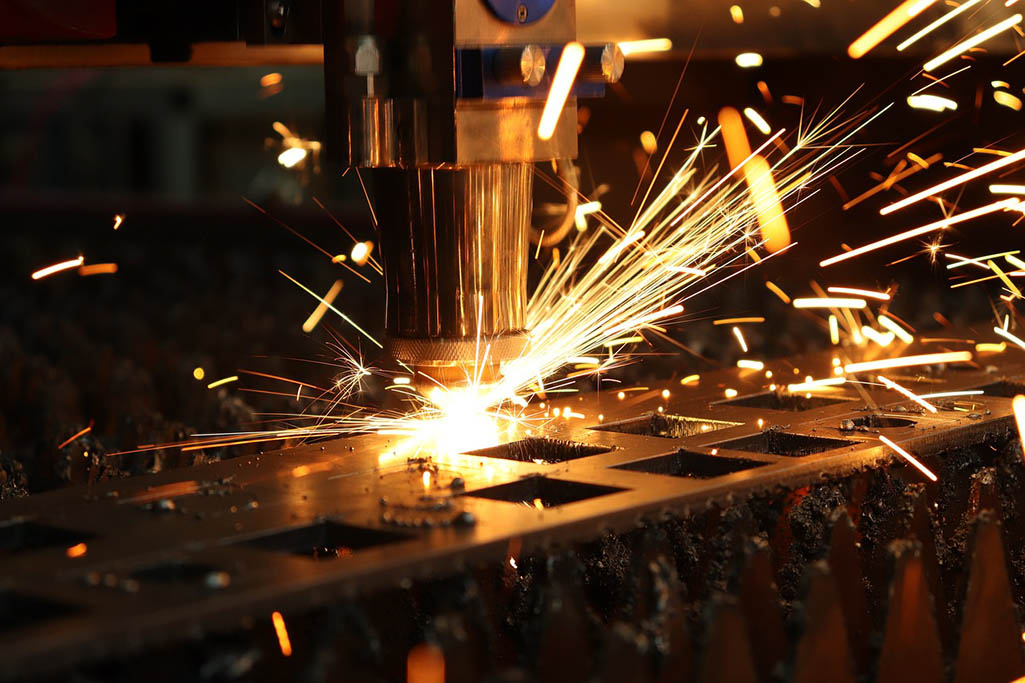

MACCHING CNC,As the intelligent cornerstone of modern manufacturing,Its basic principle contains an exquisite combination of technology and craftsmanship。CNC,computer numerical control,through preprogrammed computer instructions,Precisely control various movements of machine tools,Achieve high efficiency of parts、High precision machining。

existMACCHING CNCmiddle,Computer is the core brain。Engineers utilize professional CAD/CAM software,Convert design drawings into CNC programs readable by machine tools。These programs specify the path of the tool、Key information such as cutting parameters,Ensure accuracy during processing。

When the CNC program is loaded into the CNC machine tool,The machine tool’s control system begins to interpret and execute these instructions.。Through precision transmission devices such as servo motors,Machine tools can precisely control tool displacement and speed,Realize complex machining tasks。Whether it is simple straight line cutting,Or complex surface modeling?,CNC machining can be completed with extremely high precision and efficiency。

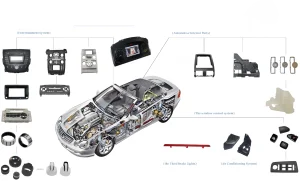

Basic principles of CNC machining,Reflects the huge advantages of digital technology in manufacturing。It makes the processing process more controllable、Predictable,Greatly improve production efficiency and parts quality。allo stesso tempo,CNC machining also offers a high degree of flexibility,Able to adapt to different shapes、Processing requirements for parts made of different materials。

In short,CNC machining is an integral part of modern manufacturing,Its basic principles and applications demonstrate digital、The huge potential of intelligent technology in manufacturing。With the continuous advancement and innovation of technology,,CNC machining will surely play a more important role in the future,Promote the development of manufacturing industry to a higher level。

Rapid Efficient is a leading provider of rapid prototyping and parts processing and manufacturing services,Concentrati sulla produzione prototipo di parti di plastica e metallo、Elaborazione personalizzata e produzione di piccoli batch,Fornire un servizio unico dal prototipo alla produzione di massa。

Con tecnologia di produzione avanzata e team altamente qualificato,Manteniamo sempre un eccellente vantaggio competitivo。I nostri servizi di produzione soddisfano le tue esigenze specifiche per la progettazione del prodotto,Compresa la lavorazione del CNC、3D Printing、Stampaggio a iniezione di sottovalutazione stampo silicone、Modanatura rapida e stampaggio a iniezione batch di piccole dimensioni, ecc.。

Il nostro modello di business si basa sulla fornitura di soluzioni economiche,Consenti ai clienti di beneficiare in tutte le fasi dello sviluppo del loro nuovo prodotto。Our most proud social value is the recognition of customers from all over the world through word-of-mouth growth.,Questi vanno da inventori o designer indipendenti a grandi industriali、Attività commerciale、medico、auto、I campi medici e altri