CNC Swiss-type machining centers, a sliding headstock automatic lathe that has become increasingly popular in recent years, offer versatile capabilities, including:

- Turning external diameters, cones, arcs, and curved surfaces

- Machining internal and external threads

- Milling slots, slotting, and spiral grooves

- Drilling and boring holes

- Tapping holes and engraving

- Knurling

These machines typically handle materials ranging from 2mm to 20mm in diameter, though larger models are available. Per esempio, the Japanese brand Nomura Swiss-type CNC machines introduced by RapidEfficient can process materials with diameters up to 25mm.

Swiss-type machines can also process irregularly shaped profiles such as hexagonal, piazza, and triangular bars. They offer:

- High precision

- Wide applications

- Exceptional versatility

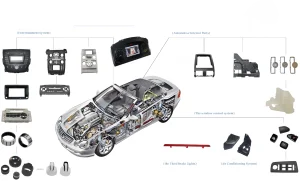

They are ideal for high-volume, high-variety, and high-precision machining of long, thin shafts and small, complex parts. Industries that benefit include:

- Medico

- Aviation and aerospace

- Military

- Automotive and motorcycles

- Communications

- Refrigeration and optics

- Home appliances and electronics

- Microelectronics, watches, and mobile phones

Improved Efficiency and Precision

CNC Swiss-type machining centers represent a qualitative leap in efficiency and accuracy compared to conventional CNC lathes.

- Dual-row tooling significantly shortens cycle time

- Reductions are achieved through:

- Tool shortening

- Multi-tool station overlap

- Thread chip effective axis movement overlap

- Direct spindle machining

The tool always operates between the spindle and the workpiece, ensuring consistent machining accuracy.

Main Advantages of CNC Swiss-type Machining

- Shortened Manufacturing Process Chain

- Milling and turning can complete all or most steps in a single operation.

- Significantly reduces the overall production process chain.

- Reduced Clamping, Improved Accuracy

- Fewer clamping times minimize errors caused by datum conversion.

- Lower Production Costs, Smaller Footprint

- Although unit machine cost is high, the process chain reduces the need for additional equipment, infissi, and workshop space.

- Lowers equipment maintenance and management costs.

- Effectively reduces total fixed asset investment.

Performance Features

- Simultaneous machining on spindle side and shaft end

- Rear toolholder equipped with Y-axis → synchronized machining front & back

- Flexible choice of guide sleeves or unguide sleeves depending on workpiece

- New software → shorter cycles, higher accuracy, easier operation

- Rapid rate control, commanded cutting feed, adjustable machining programs

- Embedded power head → enables machining of front and rear eccentric holes

- High-speed power head (up to 12,000 min⁻¹ depending on model) → faster drilling of small-diameter holes

- Automatic programming software

- Enhanced bed and tool rigidity → improved cutting capacity

- Increased transverse power head speed → stronger scraping performance

Why Choose Swiss-type Over Conventional CNC Lathes?

For precision parts with small diameters and long lengths, Swiss-type machining offers far superior performance compared to conventional CNC lathes:

- Unique structure reduces vibration of raw material

- Supports simultaneous completion of multiple processes

- Combines efficiency with unmatched precision

RapidEfficient has imported over 30 CNC Swiss-type machines from Japan, enabling:

- Rapid and precise machining of aluminum alloys, stainless steel, carbon steel, free-cutting materials, and copper alloys

- Meeting the high-standard component requirements of medical, aerospace, automobile, electronics, and other industries