What are the key points for quality control in stainless steel part processing?

Stainless steel part processing refers to the process of transforming raw materials (such as stainless steel plates, bars, pipes, and...

How to reduce part breakage during machining while maintaining dimensional accuracy?

In component manufacturing, dimensional accuracy and breakage risk are often intertwined. The higher the dimensional accuracy requirements, the more complex...

What are the typical applications of CNC 4-axis machining?

CNC 4-axis machining is a CNC machining method that adds a rotary axis (usually the A or B axis) to...

How to remove knife marks produced during stainless steel machining?

Knife marks (cutting marks) produced during stainless steel machining are surface defects caused by friction between the tool and the...

How can we ensure quality when processing non-standard hardware parts?

The processing quality of non-standard hardware parts (metal parts with non-standard specifications and customized to specific needs) directly impacts equipment...

What factors affect the cost of parts processing?

The cost of parts processing is affected by many factors, from material selection to post-processing and testing. Differences in each...

What are the accuracy and quality inspection requirements after CNC machining?

The accuracy and quality of CNC machining directly determine the assembly performance and reliability of the workpiece. After machining, systematic...

Analysis of the process flow of CNC machining parts

CNC machining is a process that uses computer programming to control machine tools for precision machining. The process flow of...

How to ensure precision in sheet metal processing?

In modern industry, precision gears and precision sheet metal parts are the critical backbone supporting the operation of high-end equipment....

How Much Does CNC Machining Cost in China?

CNC machining is renowned for its precision, speed, and flexibility, making it a preferred manufacturing method for everything from prototypes...

Análisis de las diferencias de proceso entre el mecanizado CNC de acero inoxidable y piezas de plástico

Tecnología de mecanizado CNC, with its high efficiency and precision, plays a vital role in modern manufacturing. Sin embargo, the process requirements...

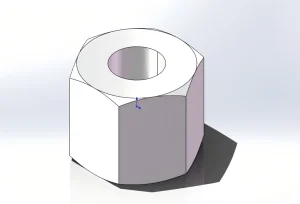

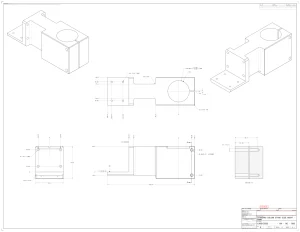

¿Por qué el mecanizado CNC requiere dibujos 2D y 3D??

Today I will explain to you why you need to provide both 2D and 3D drawings when doing CNC processing....

Post-processing of SLS Printed Parts

I. Introducción en los últimos años, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

I. Introducción en los últimos años, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

I. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: A Comprehensive Guide

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

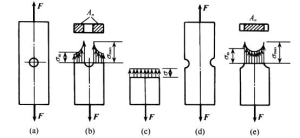

Stress concentration leads to part failure, how to effectively avoid?

I. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

I. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

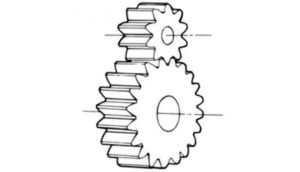

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

¿Cómo abordamos el tema del mal servicio postventa para piezas??

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

Strategies for dealing with material changes and dimensional errors in CNC lathe machining

CNC lathe machining plays a vital role in modern manufacturing due to its high precision and efficiency. Sin embargo, fluctuations in...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

Mecanizado de CNC Estrategia de mejora de la eficiencia del lote y la prueba: coincidir con el progreso del desarrollo de nuevos productos

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimizar la gestión de entrega de mecanizado CNC Meckining: mejorar la eficiencia y la coordinación de la planificación de la producción

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

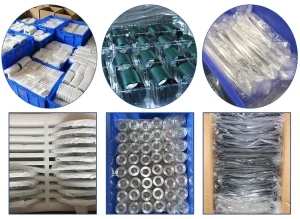

Estrategias de envasado y envío para el transporte seguro de piezas mecanizadas CNC

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

Planta de procesamiento de CNC para piezas de robot colaborativos

Las piezas de robot colaborativos están revolucionando la industria manufacturera. Estos robots funcionan junto con los humanos para mejorar la productividad y la eficiencia.. Al...

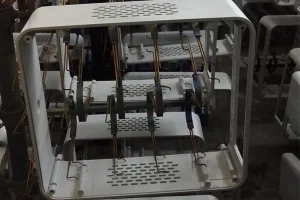

Piezas de equipos inteligentes CNC Mecanizado Solución rápida

1. Introducción en la industria manufacturera altamente desarrollada de hoy, El equipo inteligente juega un papel crucial en varios campos. De la automatización industrial ...

Piezas de equipos marinos CNC Mecanizado Solución rápida

I. Introducción en los últimos años, La industria de la ingeniería marina ha estado en auge, con la demanda global de exploración de recursos marinos,...

RapidEffient crea un estuche de computadora en miniatura para TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapidefficient’s CNC machining collaboration with North American customer SecureVision Technologies

Client Background: SecureVision Technologies, located in the vibrant tech hub of Silicon Valley, California, is a leading security technology company...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...