¿Es realmente tan difícil el mecanizado CNC de piezas de acero inoxidable de precisión??

Las piezas de precisión comunes de acero inoxidable generalmente se fabrican utilizando grados estándar como 303, 304, 316, y 420. Acero inoxidable...

Cuando la precisión se encuentra con el cielo: El riguroso arte del mecanizado CNC en el sector aeroespacial

Un avión de pasajeros moderno tiene millones de piezas., y muchos de sus componentes clave, desde las palas de la turbina del motor hasta el tren de aterrizaje..

Servicios de mecanizado CNC: Códigos de fabricación de precisión más allá “OEM”

Cuando entrega un dibujo de pieza de precisión a un proveedor de servicios de mecanizado CNC, ¿Esperas que simplemente...?.

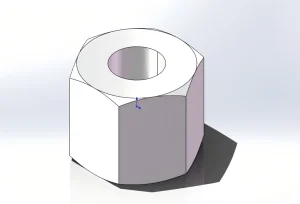

Materiales y accesorios principales utilizados en el procesamiento de piezas de precisión de la válvula

1. Accesorios principales de las válvulas 2. Materiales corporales de la válvula Los materiales corporales de la válvula deben seleccionarse de acuerdo con la presión, temperatura, corrosión...

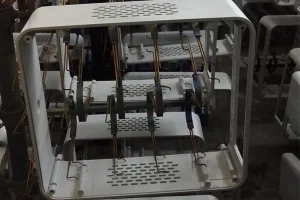

Lo que es aburrido en un centro de mecanizado CNC? ¿Cuáles son sus beneficios y desafíos??

El aburrimiento se refiere al proceso de ampliar o refinar un agujero existente en una pieza de trabajo. CNC Boring se caracteriza por ...

Mecanizado de cinco eje: Una herramienta de fabricación de precisión que empuja los límites del mecanizado CNC tradicional

En la arena de la fabricación moderna, Los servicios de mecanizado CNC han sido durante mucho tiempo una piedra angular de la fabricación de piezas de precisión. Sin embargo, como...

¿Cuáles son las áreas de productos para cada grado de extrusión de aluminio de la serie 6??

Todos sabemos que las extrusiones de aluminio se usan ampliamente en una amplia gama de aplicaciones.. El elemento principal del ...

¿Qué factores influyen en el precio de las piezas de extrusión de aluminio maquinada con precisión??

Las extrusiones de aluminio se usan ampliamente en todas las industrias, Pero sus precios varían significativamente. Si eres un fabricante o un usuario, comprensión...

Cómo el mecanizado CNC vuelve a modificar el punto de referencia de calidad para el hardware no estándar

Cuando el mecanismo de transmisión de precisión de un dispositivo médico de vanguardia funciona en silencio, y cuando un accesorio personalizado en un automatizado..

Servicios de mecanizado CNC: La fuerza impulsora central de las piezas de precisión a productos innovadores

A medida que los diseñadores dibujan dibujos y ingenieros de piezas intrincadas, conciben prototipos de productos innovadores, Surge una pregunta crítica: ¿Cómo pueden los diseños virtuales?.

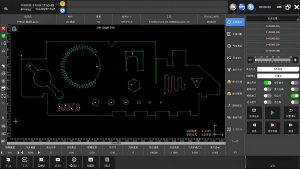

Servicios de mecanizado CNC: Análisis completo del conocimiento de la industria y la guía de selección

En el corazón de la fabricación moderna, CNC (Control numérico de la computadora) La tecnología de mecanizado se erige como un motor de precisión, conduciendo la producción..

Características geométricas de herramientas de mecanizado CNC: Ángulo de rastrillo y ángulo de espacio libre

Aplicar efectivamente las diferentes piezas de herramientas CNC para girar es una solución comprobada para reducir los costos de mecanizado. Por lo tanto, seleccionando lo apropiado ...

Guía de materiales plásticos para prototipos y producción

I. Introducción en el mundo dinámico del desarrollo de productos, Prototipos de materiales plásticos y producción son pasos cruciales que pueden hacer..

Postprocesamiento de piezas impresas SLS

I. Introducción en los últimos años, El advenimiento de la tecnología de impresión 3D ha revolucionado la fabricación, y sinterización láser selectiva (SLSS) tiene...

Consideraciones de diseño clave para la impresión 3D

1. Introducción La tecnología de impresión 3D se ha convertido en una fuerza revolucionaria en la fabricación moderna y varios otros campos. Habilita ...

Tratamiento térmico de piezas mecanizadas CNC

I. Introducción en los últimos años, La industria del mecanizado de CNC ha sido testigo de un crecimiento notable, con piezas mecanizadas CNC encontrando aplicaciones extensas..

Directrices de diseño para formar e insertar la formación de insertos

I. Introducción en el mundo dinámico de la fabricación, envolver el moldeo e insertar el soporte de moldeo como dos técnicas potentes que tienen..

¿Por qué usar molduras de envoltura e moldura de inserto??

1. Introducción en el panorama altamente competitivo del mecanizado CNC, Los fabricantes buscan constantemente técnicas innovadoras para mejorar la calidad del producto..

9 Criterios de DFM para el diseño de piezas: Una guía completa

1. Introducción a DFM en diseño en parte 1.1 ¿Qué es DFM?? DFM, o diseño para la fabricación, es un concepto crucial..

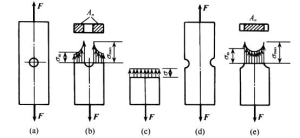

La concentración de estrés conduce a la falla de la parte, Cómo evitar efectivamente?

I. Introducción La concentración de estrés es un fenómeno donde el estrés se amplifica significativamente en áreas específicas de una parte, a menudo liderando ...

Descripción general de cuatro teorías de fuerza del aluminio

El aluminio abstracto es un metal ampliamente utilizado con propiedades únicas. Este artículo proporciona una visión general de las cuatro teorías de fuerza..

¿Qué materiales tienen buena resistencia a la corrosión??

I. Introducción La corrosión es un problema generalizado y costoso que afecta a varias industrias y nuestra vida diaria. Puede causar ...

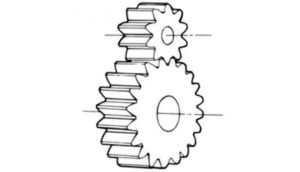

¿Qué materiales comunes son adecuados para hacer engranajes??

Los engranajes son componentes mecánicos esenciales que transmiten potencia y movimiento entre los ejes giratorios. La elección del material para hacer engranajes..

8 Procesos de mecanizado comunes, Colección recomendada

Los procesos de mecanizado juegan un papel crucial en la fabricación. Transforman las materias primas en partes precisas y funcionales.. Aquí hay 8...

Soluciones CNC de proveedores de RapidEftient

En el paisaje en constante evolución de la fabricación, La precisión y la eficiencia son primordiales. Aquí es donde CNC (Control numérico de la computadora) vienen las soluciones ...

Explore la precisión con soluciones aeroespaciales de mecanizado CNC

Introducción El mecanizado Aeroespace CNC es un aspecto crítico de la industria aeroespacial moderna. Este blog explorará el mundo de ....

Mecanizado y fabricación de precisión rápida y eficiente: Una revisión completa

Resumen Este artículo explora la importancia del mecanizado y fabricación de precisión rápida y eficiente. Elabora en el papel crucial..

Piezas de mecanizado CNC de precisión: Desentrañar la excelencia en la fabricación moderna

Resumen Este artículo discute a fondo varios aspectos de las piezas de mecanizado CNC de precisión. Aclara que las piezas de mecanizado CNC de precisión son ...

Desbloquear el potencial del metal con nuestro mecanizado de precisión de metal

Resumen Este artículo discute a fondo el mecanizado de precisión de metal, incluyendo su definición, importancia, Tipos de procesamiento y características. Se elabora en ...

Servicio de giro de CNC para una pequeña producción de lotes: Precisión y eficiencia desatada

1、Introducción ¿Qué es el servicio de giro de CNC para la producción de lotes pequeños?? El servicio de giro de CNC para la producción de lotes pequeños es especializado..

Herramientas de giro de CNC para mecanizado de precisión: Desatar la excelencia de RapidEffient

1、Introducción en el reino del mecanizado de precisión, Las herramientas de giro de CNC juegan un papel indispensable. El mecanizado de precisión es crucial para las industrias..

Desatar la eficiencia de rentabilidad del aluminio de mecanizado CNC con rapidefficiente

uno、Introducción en el ámbito del aluminio de mecanizado CNC, RapidEffient emerge como un cambio de juego. La eficiencia de rentabilidad en el mecanizado CNC es paremost..

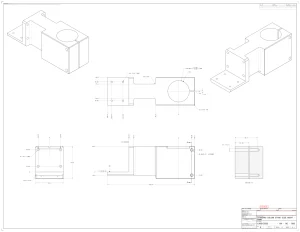

Mecanizado CNC para recintos de aluminio: Excelencia en ingeniería de precisión

1. Introducción en el ámbito de la fabricación moderna, CNC Machining ha revolucionado la producción de recintos de aluminio. Estos recintos sirven..

Prototipos de aluminio CNC: Revolucionar el desarrollo de productos con rapideftoment

1. Introducción en el paisaje altamente competitivo de la fabricación moderna, La creación de prototipos CNC de aluminio se ha convertido en una piedra angular para la innovación..

Desatar la potencia de la fabricación de piezas de aluminio CNC con rapideftoment

1、Introducción en el paisaje industrial en rápida evolución de hoy, La fabricación de piezas de aluminio CNC juega un papel crucial. Este artículo tiene como objetivo proporcionar ...

Servicios de mecanizado de aluminio CNC: Desatar precisión y eficiencia

Introducción Descripción general del mecanizado de aluminio CNC El mecanizado de aluminio CNC es un proceso altamente sofisticado y esencial en diversas industrias. Este...

Cuerpo de válvula de precisión de aleación de aluminio.

1、 Elegir los materiales adecuados ahorra 80% del problema en la etapa posterior Usamos aleación de aluminio 6061-T6 (obediente...

Manguito mecánico de precisión poroso de acero inoxidable:el “paraguas protector resistente” de equipo.

Introducción en equipos industriales., si hay un componente que puede ser como un “armadura de acero resistente”, protegiendo firmemente el...

Cuchillas de turbina mecanizada por CNC: Una obra maestra de fabricación de precisión

Introducción en el maravilloso mundo del mecanizado CNC, Cada componente es como una obra de arte meticulosamente elaborada, y el ...

Carcasa de la caja de cambios de transmisión de alta precisión

Introducción en un sistema mecánico complejo, Si hay una parte que puede ser como un “Pequeño ama de llaves cariñosa”, cual...

Conector de aleación de aluminio mecanizado por CNC: admite completamente los componentes centrales

Introducción Hola a todos, Me gustaría introducir este conector de aleación de aluminio maquinado con CNC. Como un mayordomo meticuloso, Se mantiene de forma segura todo ...

Alto – CNC de precisión – Disipadores de aluminio mecanizados: El “Guardianes geniales” por lo alto – Equipo de rendimiento en todo el mundo

Introducción Hola a todos! Hoy, Te estoy llevando en un viaje al fascinante mundo de una revolución de la gestión térmica, y...

RapidEffient crea un estuche de computadora en miniatura para TechSphere

Antecedentes en junio 2024, Nos asociamos con TechSphere en Tokio. TechSphere, con operaciones que abarcan Asia, Desde las bulliciosas calles de Seúl..

La artesanía de precisión de RapidEffient en las cerraduras de puerta electrónica inteligente para el innovador escandinavo Nordicsafe Solutions

Rapidefficient considera cada proyecto como un nuevo desafío, Y este no fue la excepción. Antecedentes temprano 2023, Nos asociamos con ...

La colaboración de mecanizado CNC de RapidEffient con Tecnologías de Vision Customer North American Customer

Antecedentes del cliente: Tecnologías SecureVision, Ubicado en el vibrante centro tecnológico de Silicon Valley, California, es una empresa líder de tecnología de seguridad..

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...