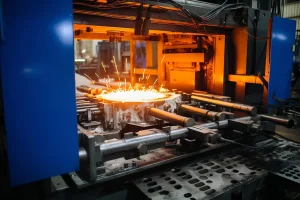

Five Key Steps of Injection Molding

Injection molding is a widely used manufacturing process for producing plastic parts. From everyday household items to intricate automotive components,...

What Plastic Is Used in Injection Molding?

Injection molding is a widely-used process in manufacturing, particularly for creating plastic parts and products. The choice of plastic is...

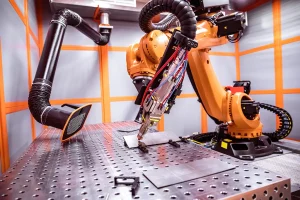

What Is the Process of Sheet Metal Processing?

Sheet metal processing is a crucial process in manufacturing, where flat metal sheets are transformed into functional parts and products....

Why Is Injection Molding So Popular?

Injection molding is a manufacturing process that has gained widespread popularity in various industries. From creating small, detailed parts to...

What are the 4 types of sheet metal processing operations?

Sheet metal processing plays a crucial role in creating parts and products for various industries. To turn flat metal sheets...

Applications of Overmolding

Overmolding is a versatile manufacturing process. It combines two or more materials into a single part. This technique offers numerous...

Advantages of Overmolding

Overmolding is a unique manufacturing process. It involves combining two or more materials into one product. This technique offers various...

The Difference Between Injection Molding and Overmolding

Injection molding and overmolding are both crucial manufacturing processes. While they share some similarities, they have distinct characteristics. Understanding these...

What is Overmolding?

Overmolding is a specialized injection molding process. It involves combining two or more materials to create a single, finished part....

What is Injection Molding?

Injection molding is a manufacturing process used to create plastic parts. It involves injecting molten plastic into a mold. This...

The Basic Process of Sheet Metal Processing

Sheet metal processing plays a crucial role in many industries, including automotive, aerospace, construction, and electronics. This process involves transforming...

Trends in the Development of Sheet Metal Processing

Sheet metal processing continues to evolve as technology advances. This process is essential across various industries, including automotive, aerospace, construction,...

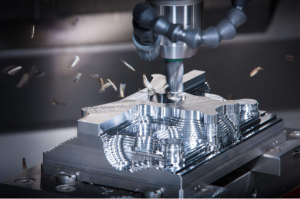

CNC Milling Machine: Ideal for Processing Which Parts?

I. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

I. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

I. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

I. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

I. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

The most common defects and solutions for CNC machining of parts

CNC machining is a high-precision manufacturing technology, but it may also encounter some common machining defects. Understanding these defects and...

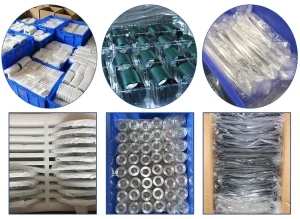

Estrategias de envasado y envío para el transporte seguro de piezas mecanizadas CNC

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

Planta de procesamiento de CNC para piezas de robot colaborativos

Las piezas de robot colaborativos están revolucionando la industria manufacturera. Estos robots funcionan junto con los humanos para mejorar la productividad y la eficiencia.. Al...

Piezas de equipos inteligentes CNC Mecanizado Solución rápida

1. Introducción en la industria manufacturera altamente desarrollada de hoy, El equipo inteligente juega un papel crucial en varios campos. De la automatización industrial ...

Piezas de equipos marinos CNC Mecanizado Solución rápida

I. Introducción en los últimos años, La industria de la ingeniería marina ha estado en auge, con la demanda global de exploración de recursos marinos,...

Piezas de comunicación óptica Mecanizado CNC Solución rápida

I. Introducción en la era digital, La comunicación óptica se ha convertido en la columna vertebral de la conectividad global. Desde acceso a Internet de alta velocidad a ...

Solución rápida para mecanizado CNC de piezas de semiconductores

I. Introducción en el panorama altamente competitivo de la industria electrónica, Las piezas de semiconductores se encuentran como el eje del avance tecnológico ....

Nuevas piezas de energía CNC Mecanizado Solución rápida

I. Introducción en los últimos años, con el rápido desarrollo de nuevas tecnologías energéticas, La demanda de nuevas piezas de energía tiene ...

Solución rápida para piezas médicas de mecanizado CNC

1. Introducción en los últimos años, La industria médica ha sido testigo de un notable crecimiento, con una creciente demanda de sofisticado y preciso..

Robot Piezas de mecanizado CNC Solución rápida

Ⅰ. Introducción en los últimos años, El campo de la robótica ha sido testigo de avances notables, revolucionando industrias en todo el mundo. De Automotive ...

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...