¿Cómo se calcula el costo de mecanizado CNC?? ¿Qué factores lo influyen??

CNC Machining es una tecnología convencional en la industria manufacturera. Debido a su alta eficiencia y precisión, muchas fábricas y ...

Mecanizado CNC para acabados de espejo de alto brillo

Introducción El mecanizado CNC puede lograr directamente un acabado de espejo de alto brillo., El mecanizado CNC de alto brillo se ha vuelto cada vez más común, Especialmente en el ...

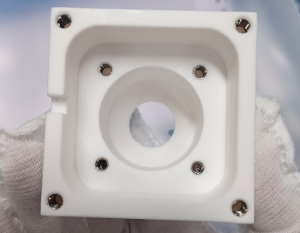

¿Pueden los centros de mecanizado CNC procesar cerámica de nitruro de aluminio??

La cerámica de nitruro de aluminio es un material con excelente conductividad térmica, y su rango de aplicación está aumentando gradualmente. Aunque nitruro de aluminio ...

Diferencias entre el mecanizado CNC y la impresión 3D

Con avances tecnológicos y revoluciones en ingeniería y maquinaria, quieres saber que estás usando el mejor equipo para avanzar..

¿Cuáles son los tipos comunes de centros de mecanizado CNC??

Los centros de mecanizado CNC son un derivado mejorado de las fresadoras CNC. Actualmente, vienen en una variedad de formas. Efecto rápido..

El “Campeón invisible” de fabricación de instrumentos de precisión: Cómo RapidEftient capacita a la tecnología de vanguardia con servicios de mecanizado CNC

En el mundo de los instrumentos de precisión, Incluso la más mínima diferencia puede ser mil millas. De escalpel que manipulan las células..

Servicios de mecanizado CNC: El “Guardianes de vida” de fabricación de precisión del dispositivo médico

Robots quirúrgicos que se mueven precisamente bajo luces sin sombras, catéteres microscópicos que viajan a través de los vasos sanguíneos, implantes ortopédicos que apoyan silenciosamente..

Ventajas clave del mecanizado de tipo suizo CNC

Centros de mecanizado de tipo suizo CNC, Un torno automático de cabezal deslizante que se ha vuelto cada vez más popular en los últimos años, ofrecer capacidades versátiles,...

¿Cuáles son los procesos de mecanizado de precisión para diferentes tipos de materiales de cobre??

Los materiales de cobre comunes incluyen: latón (una aleación compuesta de cobre y zinc), cuppronickel (una aleación compuesta de cobre y níquel),...

Proceso de procesamiento de torno CNC de aluminio

El procesamiento de tornos CNC de aluminio es un método de fabricación altamente preciso y ampliamente utilizado en la industria moderna.. Combina mecanizado avanzado..

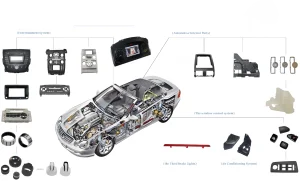

Un inventario de procesamiento de piezas automotrices de precisión

Cada automóvil se compone de miles de piezas de precisión., cada uno cumple una función única. Con más de un siglo de....

Soluciones para la dificultad del mecanizado de piezas de acero inoxidable

Mecanizado, como comúnmente nos referimos a él, Implica el uso de una herramienta de corte para eliminar el exceso de material de un espacio en blanco o....

Cómo garantizar la precisión y estabilidad de las piezas durante el procesamiento?

La importancia de la precisión y la estabilidad en el mundo de la fabricación, Especialmente en el mecanizado CNC, La precisión y la estabilidad..

La verdad sobre la precisión de las piezas en el mecanizado CNC

La idea errónea de una mayor precisión de la parte en el campo del mecanizado CNC, Muchas personas tienen una idea errónea común de que el ...

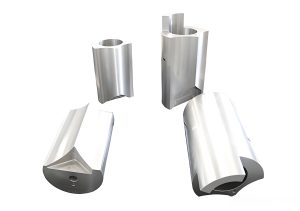

Tecnología de procesamiento de piezas de eje

Las piezas del eje son componentes esenciales en numerosas aplicaciones mecánicas e industriales. Su procesamiento adecuado es crucial para garantizar el suave..

El papel del revestimiento de níquel en la aleación de aluminio

La aleación de aluminio es un material ampliamente utilizado en varias industrias debido a sus excelentes propiedades, como, buena conductividad,...

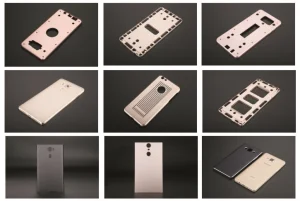

Ventajas y desventajas de las piezas de hardware de mecanizado CNC

En la industria manufacturera moderna, El mecanizado CNC se ha convertido en un proceso crucial para producir piezas de hardware de alta calidad. CNC (Computadora numérica ...

Cómo mejorar la eficiencia del procesamiento de piezas de UAV y reducir el desperdicio

En el paisaje tecnológico en rápida evolución, vehículos aéreos no tripulados (Uavs) se han vuelto cada vez más populares en varios campos, como la vigilancia,...

Tecnología de mecanizado de precisión y proceso para piezas de moho

En el campo de la fabricación, El mecanizado de precisión de las piezas de moho juega un papel crucial. Las piezas del molde son componentes esenciales en ...

Tecnología y aplicación de estampado de chapa

La tecnología de estampado de chapa es un proceso de fabricación crucial que se ha utilizado ampliamente en varias industrias. En este artículo,...

Desafíos y avances en el procesamiento de piezas de forma irregular

Introducción La fabricación de piezas de forma irregular presenta desafíos únicos para los ingenieros, diseñadores, y fabricantes. A diferencia de las geometrías estándar, partes irregulares ...

6 Puntos de conocimiento esencial para el mecanizado de acero inoxidable

Introducción: El mecanizado de acero inoxidable es un proceso crítico en muchas industrias, de dispositivos aeroespaciales a médicos. Su alta fuerza, durabilidad,...

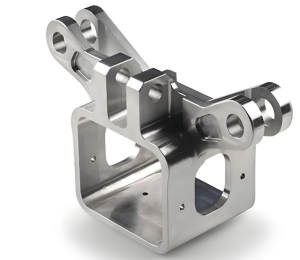

Explicación detallada de la precisión del mecanizado CNC

1. Introducción a la precisión del mecanizado de CNC CNC (Control numérico de la computadora) El mecanizado se ha convertido en uno de los métodos más cruciales de ....

Aplicaciones de materiales de teflón en la industria del mecanizado

Introducción: Teflón, Una marca para politetrafluoroetileno (Ptfe), ha ganado una popularidad generalizada en la industria del mecanizado debido a su excepcional..

Mecanizado de cnc de aluminio de alta precisión: Una descripción completa

1、Introducción al mecanizado CNC de aluminio de alta precisión Mecanizado de aluminio CNC de alta precisión El mecanizado es un proceso crucial en la fabricación moderna. Implica el ...

Las ventajas y aplicaciones del mecanizado de aluminio CNC en la fabricación moderna

Resumen Este artículo analiza la importancia del mecanizado de aluminio CNC en la fabricación moderna. Elabora sobre los antecedentes de la investigación y ....

Mecanizado de aluminio de grado aeroespacial: Precisión en los cielos

1、Comprender el mecanizado de aluminio de aluminio de grado aeroespacial de grado aeroespacial que juega un papel crucial en la industria aeroespacial. El aluminio de grado aeroespacial es un especializado..

Tolerancias de mecanizado de aluminio CNC

Resumen Este documento proporciona un análisis completo de las tolerancias de mecanizado de aluminio CNC. Se identifican los factores clave que determinan estas tolerancias, incluido...

Mecanizado de aluminio CNC: Desatar precisión y eficiencia

I. Perspectivas del núcleo 1.1 Procesos clave Transformaciones de conducción en el procesamiento de aluminio CNC de fabricación: Una tecnología vital en la fabricación moderna CNC..

Mecanizado de prototipo de aluminio CNC: Desatar precisión e innovación

uno、Comprensión del mecanizado del prototipo de aluminio CNC (一) ¿Qué es el mecanizado del prototipo de aluminio CNC?? El mecanizado de prototipo de aluminio CNC se refiere al proceso de ...

Informe de investigación sobre mecanizado aeroespacial de aluminio CNC

1. Puntos de vista del núcleo 1.1 Tecnología de fabricación clave que impulsa el desarrollo aeroespacial Aeroespace CNC El mecanizado de aluminio es de importancia crucial en el ...

Cuerpo de válvula de precisión de aleación de aluminio.

1、 Elegir los materiales adecuados ahorra 80% del problema en la etapa posterior Usamos aleación de aluminio 6061-T6 (obediente...

Manguito mecánico de precisión poroso de acero inoxidable:el “paraguas protector resistente” de equipo.

Introducción en equipos industriales., si hay un componente que puede ser como un “armadura de acero resistente”, protegiendo firmemente el...

Cuchillas de turbina mecanizada por CNC: Una obra maestra de fabricación de precisión

Introducción en el maravilloso mundo del mecanizado CNC, Cada componente es como una obra de arte meticulosamente elaborada, y el ...

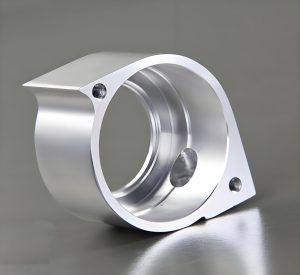

Carcasa de la caja de cambios de transmisión de alta precisión

Introducción en un sistema mecánico complejo, Si hay una parte que puede ser como un “Pequeño ama de llaves cariñosa”, cual...

Conector de aleación de aluminio mecanizado por CNC: admite completamente los componentes centrales

Introducción Hola a todos, Me gustaría introducir este conector de aleación de aluminio maquinado con CNC. Como un mayordomo meticuloso, Se mantiene de forma segura todo ...

Alto – CNC de precisión – Disipadores de aluminio mecanizados: El “Guardianes geniales” por lo alto – Equipo de rendimiento en todo el mundo

Introducción Hola a todos! Hoy, Te estoy llevando en un viaje al fascinante mundo de una revolución de la gestión térmica, y...

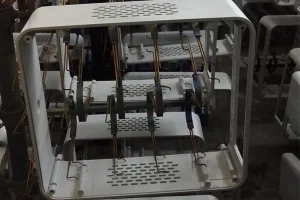

RapidEffient crea un estuche de computadora en miniatura para TechSphere

Antecedentes en junio 2024, Nos asociamos con TechSphere en Tokio. TechSphere, con operaciones que abarcan Asia, Desde las bulliciosas calles de Seúl..

La artesanía de precisión de RapidEffient en las cerraduras de puerta electrónica inteligente para el innovador escandinavo Nordicsafe Solutions

Rapidefficient considera cada proyecto como un nuevo desafío, Y este no fue la excepción. Antecedentes temprano 2023, Nos asociamos con ...

La colaboración de mecanizado CNC de RapidEffient con Tecnologías de Vision Customer North American Customer

Antecedentes del cliente: Tecnologías SecureVision, Ubicado en el vibrante centro tecnológico de Silicon Valley, California, es una empresa líder de tecnología de seguridad..

Estudio de caso de colaboración de clientes de Rapidefficiente – Grupo de tecnologías O-Net

Estudio de caso de colaboración de clientes de Rapidefficiente: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Grupo Co., Ltd es un prominente..

Estudio de caso de colaboración de clientes de Rapidefficiente – Tecnologías Shenzhen Colibri

Estudio de caso de colaboración de clientes de Rapidefficiente: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd es una alta tecnología..

Servicios de mecanizado mecánico asequible sin comprometer la calidad

Introducción en el mundo de fabricación de hoy, Encontrar servicios de mecanizado mecánico asequible que también brinde calidad y confiabilidad es crucial. Empresas a través de ...