We all know that aluminum extrusions are primarily composed of aluminum, with other metals and non-metals, such as magnesium, manganese, copper, silicon, and zinc, added to form an alloy through a series of processes, including heating, extrusion, and surface treatment. Aluminum extrusions are designated by different alloying elements, and each grade corresponds to a different industry, such as automotive and aerospace applications.

The main alloying elements commonly added to aluminum extrusions are magnesium, copper, silicon, zinc, and manganese. Minor elements include chromium, nickel, lithium, iron, and titanium, as well as some impurity elements such as vanadium, beryllium, calcium, lead, antimony, tin, bismuth, and sodium. Although these impurity elements are generally present in very low concentrations, they can still affect the quality of aluminum extrusions.

Calcium

Calcium reacts with silicon to form CaSi, which improves the conductivity of pure aluminum. Calcium reacts with aluminum to form calcium aluminide compounds, which are insoluble in aluminum and can alter the machinability of aluminum alloys. The resulting calcium aluminides cannot strengthen aluminum extrusions during heat treatment. Small amounts of calcium can remove hydrogen from molten aluminum but may reduce the mechanical properties of aluminum extrusions.

Vanadium

Vanadium forms compounds such as Al₃V in aluminum alloys, which refine grain size during the casting process, refine the recrystallized structure, and increase the crystallization temperature. Sin embargo, it is difficult to melt, and its refining effect is not as strong as that of titanium and zirconium. Adding a small amount of vanadium can make the surface of aluminum extrusions smoother.

Sodium

Sodium has a very low melting point and very low solubility in aluminum. When aluminum extrusions containing sodium are melted and heated, sodium can segregate at grain boundaries and cause brittle cracking or form sodium-containing intermetallics such as NaAlSi. When the magnesium content exceeds 2%, free sodium may precipitate, causing sodium embrittlement. Por lo tanto, sodium-based fluxes are not allowed in high-magnesium aluminum alloys. Sin embargo, bismuth can be added to prevent sodium embrittlement. Chlorination can also remove sodium as sodium chloride. Adding bismuth to aluminum-magnesium alloys can form bismuth compounds that mitigate embrittlement. Sodium can reduce the load-bearing capacity and mechanical strength of aluminum extrusions.

Antimony

Antimony is primarily used as a modifier in cast aluminum alloys and is rarely used in wrought aluminum alloys. It can be used in aluminum-magnesium alloys to prevent sodium embrittlement cracking as a substitute for bismuth. Adding antimony to certain aluminum-magnesium-zinc-copper alloys can improve hot and cold workability and enhance the mechanical properties of aluminum extrusions.

Beryllium

Beryllium is toxic and can cause allergic reactions. Por lo tanto, it must be avoided in aluminum extrusions used for food and beverage applications to ensure food and personal safety. Adding trace amounts of beryllium to wrought aluminum alloys can improve the oxide film structure and reduce oxidation losses and inclusions during casting. For aluminum extrusions used as welding materials, the beryllium content should be controlled below 8 μg/m³ in the workplace atmosphere.

Lead, Tin, and Bismuth

Lead, tin, and bismuth have very low melting points and low solid solubility in aluminum, which can reduce the strength and machinability of aluminum extrusions and affect their mechanical properties and load-bearing capacity. Bismuth expands during solidification, providing shrinkage compensation for aluminum extrusions. Adding bismuth to aluminum-magnesium alloys can also prevent sodium embrittlement cracking, making it suitable for use in wrought aluminum alloys.

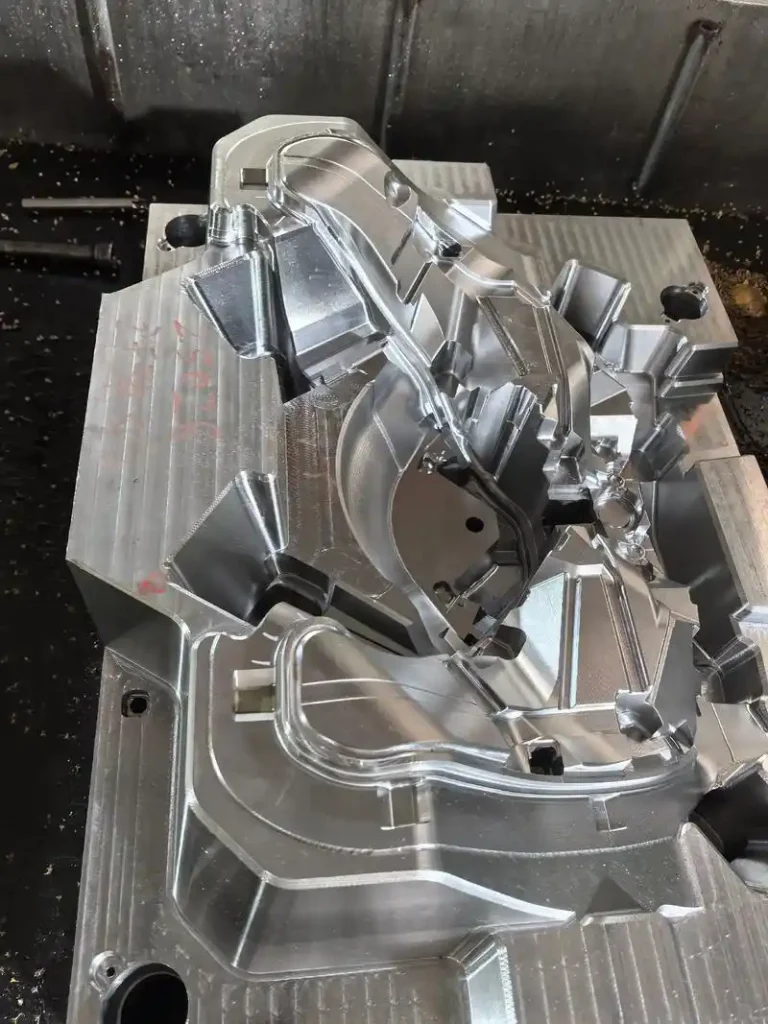

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive, and office automation parts.

The company’s CNC machining centers include four-axis, five-axis, and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers, and other precision testing equipment.

Machining accuracy: arriba a 0.01 mm

Testing accuracy: arriba a 0.001 mm