The dividing head is an important accessory for CNC milling machines. It is generally used to mount workpieces for milling inclined surfaces, performing indexing operations, and machining spiral grooves. Sin embargo, workshop operators often encounter the issue of the dividing head not locking properly during operation. This is a serious problem—if not resolved promptly, it can affect the entire machining process. Entonces, what exactly is the role of the dividing head, and how can it be adjusted?

Functions of the Milling Machine Dividing Head

The dividing head allows various indexing operations through different indexing methods, including simple indexing, compound indexing, and differential indexing. It is also used for machining spiral grooves.

When performing these operations, the dividing head enables the workpiece to be mounted at the required angle for cutting (such as milling inclined surfaces).

When milling spiral grooves, the dividing head’s gear shaft is connected to the milling table’s lead screw using an exchange gear, allowing the workpiece mounted on the dividing head to perform helical motion as the table moves.

Adjustment Method for a Loose Dividing Head Lock

If the dividing head lock becomes loose:

- Remove the lock and insert a thin copper shim inside.

- Reinstall and tighten the lock.

El meshing clearance between the worm gear and worm wheel in the dividing head must be properly adjusted.

- If the clearance is too tight, it will cause premature wear of the worm wheel.

- If the clearance is too loose, the indexing accuracy will decrease.

In general, the clearance should be maintained between 0.02–0.04 mm.

When clamping the workpiece on the dividing head, always lock the dividing head spindle first.

Avoid using excessive force during tightening, y never strike the workpiece.

During indexing operations:

- Rotate clockwise whenever possible.

- Maintain a uniform speed and smooth motion.

- If you overshoot the indexing mark, rotate the handle back more than half a turn to eliminate the clearance, then slowly move the locating pin forward again to the correct position.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products serve industries including medical, communications, optics, drones, intelligent robotics, automotor, and office automation.

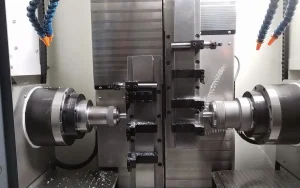

The company’s CNC machining centers include four-axis, five-axis, and multi-linkage machine tools, equipped with precision projectors, coordinate measuring machines (Cmm), spectrometers, and other precision testing instruments.

Machining accuracy can reach 0.01 mm, while testing accuracy can reach 0.001 mm.