What are the accuracy and quality inspection requirements after CNC machining?

The accuracy and quality of CNC machining directly determine the assembly performance and reliability of the workpiece. After machining, systematic...

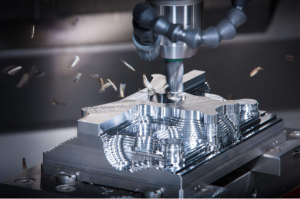

Analysis of the process flow of CNC machining parts

CNC machining is a process that uses computer programming to control machine tools for precision machining. The process flow of...

How to ensure precision in sheet metal processing?

In modern industry, precision gears and precision sheet metal parts are the critical backbone supporting the operation of high-end equipment....

How Much Does CNC Machining Cost in China?

CNC machining is renowned for its precision, speed, and flexibility, making it a preferred manufacturing method for everything from prototypes...

Analysis of the process differences between CNC machining stainless steel and plastic parts

CNC machining technology, with its high efficiency and precision, plays a vital role in modern manufacturing. However, the process requirements...

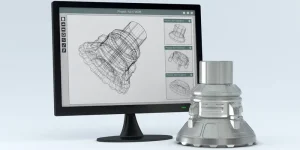

Why does CNC machining require 2D and 3D drawings?

Today I will explain to you why you need to provide both 2D and 3D drawings when doing CNC processing....

Aluminum alloy CNC machining parts: advantages and disadvantages of different models

Aluminum alloys are widely used in CNC machining due to their light weight, high strength, good thermal conductivity and corrosion...

Stainless steel CNC machining parts: advantages and disadvantages of different models

Stainless steel is widely used in CNC machining due to its excellent corrosion resistance, high strength and temperature resistance. Different...

Brass CNC machining parts: advantages and disadvantages of different models

Brass, as an alloy of copper and zinc, is highly favored in the field of CNC machining due to its...

Plastic CNC machining parts: pros and cons of different models

Plastic CNC machining parts: advantages and disadvantages of different models In modern manufacturing, plastic materials occupy an important position in...

How to improve the yield and output of precision parts?

In CNC processing manufacturers, the problems of low parts yield and insufficient production often lead to delayed delivery to customers,...

What does CNC machining DFM feasibility mean?

In the manufacturing industry, DFM (Design for Manufacturability) is a crucial concept. The purpose of DFM is to consider the...

CNC Milling Machine: Ideal for Processing Which Parts?

I. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

I. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

I. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

I. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

I. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

I difetti e le soluzioni più comuni per la lavorazione a CNC delle parti

La lavorazione a CNC è una tecnologia di produzione ad alta precisione, ma può anche incontrare alcuni difetti di lavorazione comuni. Understanding these defects and...

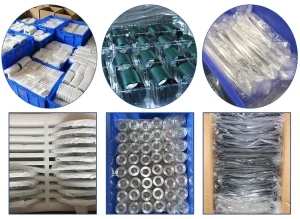

Strategie di imballaggio e spedizione per il trasporto sicuro delle parti lavorate a CNC

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...

Intelligent equipment parts CNC machining fast solution

1. Introduction In today’s highly developed manufacturing industry, intelligent equipment plays a crucial role in various fields. From industrial automation...

Marine equipment parts CNC machining fast solution

I. Introduction In recent years, the marine engineering industry has been booming, with the global demand for marine resources exploration,...

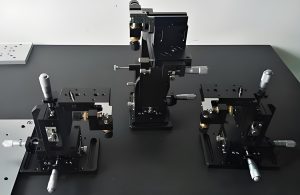

Optical communication parts CNC machining fast solution

I. Introduction In the digital age, optical communication has become the backbone of global connectivity. From high-speed internet access to...

Fast solution for CNC machining of semiconductor parts

I. Introduction In the highly competitive landscape of the electronics industry, semiconductor parts stand as the linchpin of technological advancement....