What kind of aluminum is suitable for wire drawing?

What is wire drawing? Wire drawing refers to the use of sandpaper to repeatedly scrape the surface of aluminum alloy...

Shell cutting can be laser cutting or CNC cutting

In the process of customizing aluminum shells, the choice of process is crucial. Faced with the same effect of aluminum...

What are the processing technologies for aluminum alloy?

Aluminum alloy processing technology refers to the use of a series of mechanical and chemical methods to shape metal materials...

What materials are used to make the prototype?

Prototypes belong to the processing and customization industry. They are mainly used for verification and submission during the development of...

How does rapid prototyping technology change the future of manufacturing?

Rapid prototyping technology is now becoming a standard for manufacturing companies. It facilitates faster production times while reducing operating costs....

Process requirements for stamping and stretching

There are many kinds of stamping processes, and stretching is one of them. This process has a wide range of...

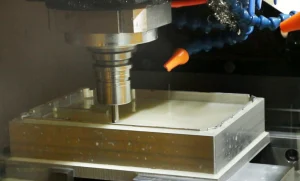

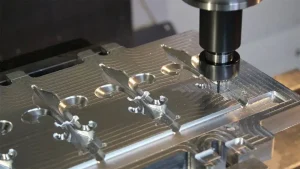

Common cutting methods of CNC machining centers

Common cutting methods in CNC machining centers are divided into six categories: reciprocating cutting; unidirectional cutting; unidirectional cutting along the...

Let’s learn about aluminum alloy

Aluminum alloy is the most widely used type of nonferrous metal structural material in industry, and has been widely used...

What is rapid tooling? What are its advantages? How fast can it be produced?

Molds are a mainstream and conventional manufacturing technology for the industry. Rapid molds, as the name implies, are mold production...

What is five-axis machining and what are its advantages and disadvantages?

What is an axis? An axis is a mechanical part that rotates or moves a workpiece or tool. The spindle...

The development trend and future prospects of injection molds

Injection molds are molds used to form plastic products. Mold design and manufacturing need to consider multiple factors, such as...

“Combined processing” shocks traditional processing! The combination of CNC and metal 3D printing

Combined processing technology refers to a processing method that combines traditional metal 3D printing and CNC two different processing technologies,...

Machining of Small Components for Robots

Introduction The Significance of Small Components in Robotics In the realm of robotics, Small Components for Robots play a role...

Precision micro-component processing

1. Introduction 1.1 The Significance of Precision Micro-components In modern manufacturing, precision micro-components play a pivotal role. These tiny yet...

2024 China CNC High-Speed Machining Center Machine Industry Research Report

In the rapidly evolving world of manufacturing, China has emerged as a global leader in the CNC high-speed machining center...

Electronic assembly mechanical parts Processing

Electronic assembly machinery forms the backbone of modern manufacturing, enabling the production of intricate electronic devices. Behind this efficiency lies...

All Kinds of Testing Machinery and Equipment Parts Processing

Introduction Testing machinery plays a critical role in various industries, ensuring the quality, durability, and functionality of products. As industries...

Why will the precision of precision hardware parts become worse?

Introduction In the world of manufacturing, precision hardware parts processing is of utmost importance. Precision hardware parts are the building...

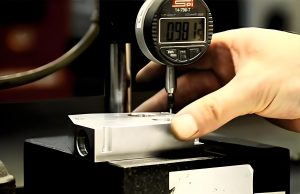

What are the measurement methods for precision parts processing accuracy?

Introduction In the field of precision parts machining measurement, ensuring high – level processing accuracy is of utmost importance. The...

Non-standard titanium alloy parts customized

Introduction In contemporary manufacturing, the demand for non – standard titanium alloy parts customized is on the rise. Titanium alloy,...

Titanium processing process

Introduction Titanium, a remarkable metal, has been captivating the attention of various industries due to its unique set of...

Importance of tungsten steel for precision parts processing

Introduction In the world of precision parts processing, tungsten steel has emerged as a material of utmost importance. Its unique...

How can precision parts processing manufacturers improve production efficiency

Introduction In the highly competitive field of precision parts processing, precision parts processing manufacturers are constantly seeking ways to enhance...

Precision Parts Processing Fixture Regulations

Introduction In the realm of CNC machining, precision parts processing fixtures play a pivotal role. They are the unsung heroes...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

I difetti e le soluzioni più comuni per la lavorazione a CNC delle parti

La lavorazione a CNC è una tecnologia di produzione ad alta precisione, ma può anche incontrare alcuni difetti di lavorazione comuni. Understanding these defects and...

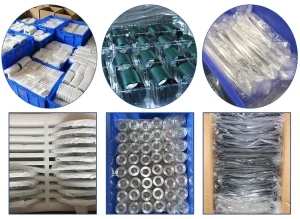

Strategie di imballaggio e spedizione per il trasporto sicuro delle parti lavorate a CNC

As a professional CNC processing factory, we know that every step from the product leaving the factory to the hands...

CNC Processing Plant for Collaborative Robot Parts

Collaborative robot parts are revolutionizing the manufacturing industry. These robots work alongside humans to enhance productivity and efficiency. At the...

Intelligent equipment parts CNC machining fast solution

1. Introduction In today’s highly developed manufacturing industry, intelligent equipment plays a crucial role in various fields. From industrial automation...

Marine equipment parts CNC machining fast solution

I. Introduction In recent years, the marine engineering industry has been booming, with the global demand for marine resources exploration,...

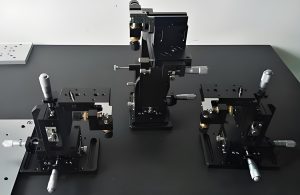

Optical communication parts CNC machining fast solution

I. Introduction In the digital age, optical communication has become the backbone of global connectivity. From high-speed internet access to...

Fast solution for CNC machining of semiconductor parts

I. Introduction In the highly competitive landscape of the electronics industry, semiconductor parts stand as the linchpin of technological advancement....

Case study di collaborazione per clienti rapide. – Gruppo O-Net Technologies

Case study di collaborazione per clienti rapide.: O-Net Technologies Group Co., Ltd Collaboration Background O-Net Technologies (Shenzhen) Group Co., Ltd is a prominent...

Case study di collaborazione per clienti rapide. – Shenzhen Colibri Technologies

Case study di collaborazione per clienti rapide.: Shenzhen Colibri Technologies Co., Ltd Collaboration Background Shenzhen Colibri Technologies Co., Ltd is a high-tech...

Affordable Mechanical Machining Services Without Compromising Quality

Introduction In today’s manufacturing world, finding affordable mechanical machining services that also deliver quality and reliability is crucial. Businesses across...