What are the main considerations for the geometric angles of CNC turning and milling?

When turning slender shafts, due to the poor rigidity of the workpiece, the shapes of the turning tool have a...

Key Measures for Ensuring Dimensional Accuracy in CNC Machined Precision Parts

The dimensional accuracy of precision parts directly impacts product quality and performance. Achieving high-precision machining requires a systematic approach, including...

How to improve and solve the poor surface accuracy of CNC machining?

In CNC machining, surface accuracy is one of the most critical indicators of part quality, directly affecting assembly precision, wear...

Why is the material selection important for CNC turning and milling?

In CNC turning-milling, material selection directly impacts machining efficiency, part accuracy, surface quality, and final performance. Its importance lies in...

Analysis of Troubleshooting Handwheel Failures During CNC Machining

CNC machining is widely used across industries and manufacturers. During the manufacturing process, unexpected or human-caused failures are unavoidable, particularly...

Analysis of Causes of Oil Leakage in CNC Machining Centers

During CNC machining, unexpected issues often arise, but no matter what they are, they must be addressed promptly. Oil leaks...

What Problems Can Arise from Improperly Arranging CNC Machining Processes?

1. Excessively Fragmented CNC Machining Processes This problem arises from a fear of complexity (referring to setup time), a preference...

How to prevent common wear problems in part machining?

Common types of wear in part machining include: Run-in Wear Run-in wear is wear that occurs when a machine tool...

What factors should be considered when selecting cutting tools?

When selecting cutting tools, appropriate cutting tools and tool holders should be selected based on the function of the machining...

CNC 4軸の機械加工は、効率と品質をどのように改善できますか?

CNC 4軸加工, 効率を改善し、品質を確保するには、複数の側面にわたって調整された努力が必要です, プロセス計画を含む, プログラミング...

CNCの機械加工とソリューションのおしゃべりマーク

CNC加工のおしゃべりマークは、多くの場合、さまざまな要因によって引き起こされます. いくつかの可能なソリューションを次に示します: CNC加工。.

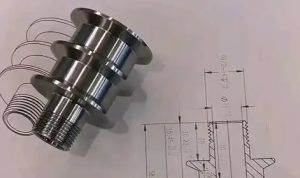

Complex Part Machining Services Where Precision Meets Complexity

Introduction In the world of manufacturing, complex part mechanical machining is a crucial process. It enables the creation of highly precise,...

Achieve High Precision with Expert Mechanical Machining Solutions

Introduction High precision mechanical machining solutions are essential for modern industries where exactness and performance are paramount. From aerospace to...

Discover Custom CNC Mechanical Machining Services Tailored to Your Needs

Introduction In the competitive world of manufacturing, precision is crucial. Custom CNC mechanical machining services have become essential for...

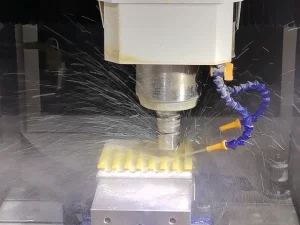

What are the steps of CNC machining?

In today’s era of rapid technological development, CNC machining has become an indispensable part of the manufacturing industry. It not...

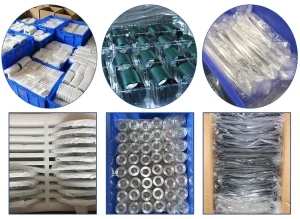

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

CNC旋盤の機械加工の重要な変更と寸法エラーに対処するための戦略

CNC旋盤の機械加工は、その精度と効率が高いため、現代の製造において重要な役割を果たします. しかし, の変動...

CNCの機械加工小さなバッチとプルーフ効率改善戦略: 新製品開発の進捗状況に一致します

新製品開発の過程で, CNC加工の小型バッチの生産と校正は、しばしばに影響する重要な要因になります。.

CNC加工配信管理を最適化します: 生産計画の効率と調整を改善します

CNCの機械加工の配信の頻繁な遅延は、生産計画の安定性に影響するだけではありません, しかし、コストも増加します。.

顧客のフィードバックと苦情をどのように処理しますか?

CNC処理業界で, 顧客のフィードバックと苦情は、企業がサービスを継続的に改善および強化するための重要な基盤です。.

部品のCNC加工のための最も一般的な欠陥とソリューション

CNC加工は、高精度の製造技術です, しかし、それはまた、いくつかの一般的な機械加工の欠陥に遭遇する可能性があります. これらの欠陥を理解する.

共同ロボット部品のCNC処理プラント

共同ロボット部品は、製造業に革命をもたらしています. これらのロボットは、生産性と効率を向上させるために人間と一緒に機能します. ..で.

インテリジェントな機器部品CNC加工高速ソリューション

1. 今日の高度に発展した製造業での紹介, インテリジェントな機器は、さまざまな分野で重要な役割を果たします. 産業用自動化から...