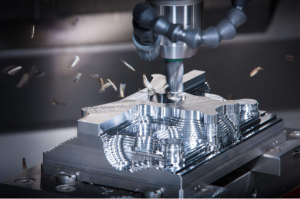

How can we reduce breakage during precision part machining by maintaining dimensional accuracy?

In precision part machining, dimensional accuracy and breakage risk are often intertwined. The higher the dimensional accuracy requirements, the more...

What are the typical applications of CNC 4-axis machining?

CNC 4-axis machining is a CNC machining method that adds a rotary axis (usually the A or B axis) to...

How to remove knife marks produced during stainless steel machining?

Knife marks (cutting marks) produced during stainless steel machining are surface defects caused by friction between the tool and the...

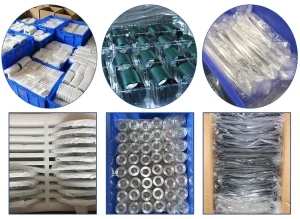

How can we ensure quality when processing non-standard hardware parts?

The processing quality of non-standard hardware parts (metal parts with non-standard specifications and customized to specific needs) directly impacts equipment...

What factors influence the cost of precision parts machining?

The cost of precision parts machining is influenced by a variety of factors, from material selection to post-processing testing. Differences...

What are the accuracy and quality inspection requirements after CNC machining?

The accuracy and quality of CNC machining directly determine the assembly performance and reliability of the workpiece. After machining, systematic...

Analysis of the process flow of CNC machining parts

CNC machining is a process that uses computer programming to control machine tools for precision machining. The process flow of...

How to ensure precision in sheet metal processing?

In modern industry, precision gears and precision sheet metal parts are the critical backbone supporting the operation of high-end equipment....

How Much Does CNC Machining Cost in China?

CNC machining is renowned for its precision, speed, and flexibility, making it a preferred manufacturing method for everything from prototypes...

Analysis of the process differences between CNC machining stainless steel and plastic parts

CNC machining technology, with its high efficiency and precision, plays a vital role in modern manufacturing. しかし, the process requirements...

Why does CNC machining require 2D and 3D drawings?

Today I will explain to you why you need to provide both 2D and 3D drawings when doing CNC processing....

Aluminum alloy CNC machining parts: advantages and disadvantages of different models

Aluminum alloys are widely used in CNC machining due to their light weight, high strength, good thermal conductivity and corrosion...

CNC Milling Machine: Ideal for Processing Which Parts?

私. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

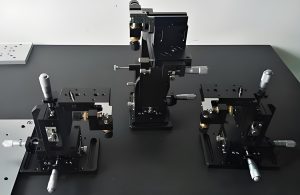

Wire-cut Machining: The Precision Power in CNC Realm

私. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

私. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” that...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

Introduction:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

私. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

私. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、Introduction 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Strategies to improve CNC machining efficiency of non-standard parts

In the manufacturing industry, CNC machining of non-standard mechanical parts is a complex and delicate process. Improving the efficiency of...

CNC machining small batch and proofing efficiency improvement strategy: matching new product development progress

In the process of new product development, small-batch production and proofing of CNC machining often become key factors affecting the...

Optimize CNC machining delivery management: improve production planning efficiency and coordination

Frequent delays in CNC machining delivery not only affect the stability of production plans, but also increase the cost and...

Treatment and prevention strategies of defective products in CNC machining

In the field of CNC machining, the appearance of defective products not only affects production efficiency, but may also have...

How do we handle customer feedback and complaints?

In the CNC processing industry, customer feedback and complaints are important bases for companies to continuously improve and enhance service...

部品のCNC加工のための最も一般的な欠陥とソリューション

CNC加工は、高精度の製造技術です, しかし、それはまた、いくつかの一般的な機械加工の欠陥に遭遇する可能性があります. これらの欠陥を理解する.

共同ロボット部品のCNC処理プラント

共同ロボット部品は、製造業に革命をもたらしています. これらのロボットは、生産性と効率を向上させるために人間と一緒に機能します. ..で.

インテリジェントな機器部品CNC加工高速ソリューション

1. 今日の高度に発展した製造業での紹介, インテリジェントな機器は、さまざまな分野で重要な役割を果たします. 産業用自動化から...

半導体部品のCNC加工のための高速ソリューション

私. エレクトロニクス業界の非常に競争の激しい状況の紹介, 半導体の部品は、技術の進歩のリンクピンとして立っています....