Is plastic deposition molding sustainable?

As an innovative manufacturing technology that has received much attention in recent years, plastic deposition molding technology has set off...

What are the commonly used sheet metal processing technologies?

Sheet metal processing is a process of processing metal sheets into the required shape and size through a series of...

Development Trend of Precision Hardware Parts

As an important part of modern industry, the development trend of precision hardware parts affects the progress of many industries....

What are the most commonly used CNC machine tools?

In the vast field of modern manufacturing, CNC machine tools play a vital role. Among them, CNC milling machines and...

Exploring the application of precision hardware parts

With the rapid development of science and technology, precision hardware parts have become an indispensable part of our daily life...

Advantages of precision hardware parts

In the vast world of manufacturing, precision hardware parts play a vital role. They not only support the normal operation...

Discussion on the recycling possibility of plastic deposition molding products

In today’s rapidly developing society, plastic products are everywhere. Whether it is water cups and tableware in daily life or...

What are precision hardware parts?

In the vast manufacturing industry, precision hardware parts are like precise gears, driving the operation of the entire industry. They...

What materials are used in plastic deposition molding?

In today’s rapidly changing technology, plastic deposition molding technology, which is what we usually call FDM (fused deposition molding) technology...

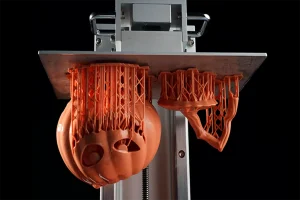

The process of plastic deposition molding

In modern manufacturing, plastic deposition molding is changing the traditional appearance of product design and production step by step with...

Precision and accuracy in CNC machining: the main difference

CNC加工の分野, precision and accuracy are two key elements that are often confused but actually have...

Multi-field application of plastic deposition molding technology

Plastic deposition molding technology, the shining pearl of modern manufacturing, shines in many fields. From daily gadgets to high-tech precision...

Guide to plastic materials for prototyping and production

私. Introduction In the dynamic world of product development, Prototyping plastic materials and production are crucial steps that can make...

Post-processing of SLS Printed Parts

私. 近年のはじめに, the advent of 3D printing technology has revolutionized manufacturing, and Selective Laser Sintering (SLS) has...

Key design considerations for 3D printing

1. Introduction 3D printing technology has emerged as a revolutionary force in modern manufacturing and various other fields. It enables...

Heat Treatment of CNC Machined Parts

私. 近年のはじめに, the CNC machining industry has witnessed remarkable growth, with CNC machined parts finding extensive applications...

Design guidelines for wrap forming and insert forming

私. Introduction In the dynamic world of manufacturing, wrap molding and insert molding stand as two powerful techniques that have...

Why use wrap molding and insert molding?

1. Introduction In the highly competitive landscape of CNC machining, manufacturers are constantly seeking innovative techniques to enhance product quality...

9 DFM Criteria for Part Design: 包括的なガイド

1. Introduction to DFM in Part Design 1.1 What is DFM? DFM, or Design for Manufacturing, is a crucial concept...

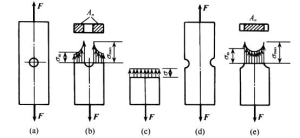

Stress concentration leads to part failure, how to effectively avoid?

私. Introduction Stress concentration is a phenomenon where stress is significantly amplified in specific areas of a part, often leading...

Overview of Four Strength Theories of Aluminum

Abstract Aluminum is a widely used metal with unique properties. This article provides an overview of the four strength theories...

What Materials Have Good Corrosion Resistance?

私. Introduction Corrosion is a pervasive and costly issue that affects various industries and our daily lives. It can cause...

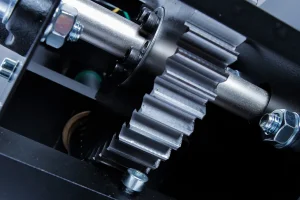

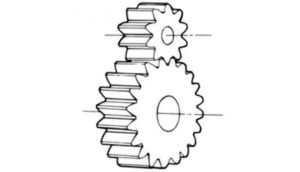

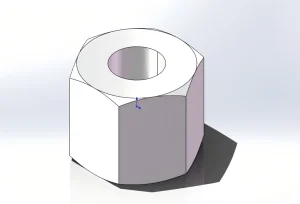

What common materials are suitable for making gears?

Gears are essential mechanical components that transmit power and motion between rotating shafts. The choice of material for making gears...

8 common machining processes, recommended collection

Machining processes play a crucial role in manufacturing. They transform raw materials into precise and functional parts. Here are 8...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

私. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

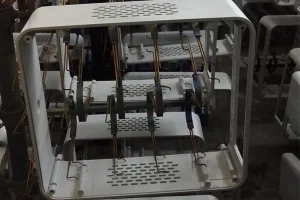

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

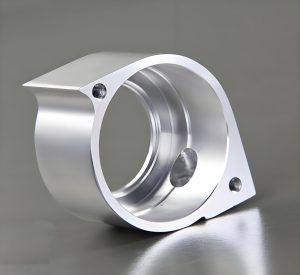

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

高い – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, そして...

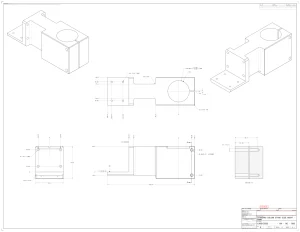

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapideffisitの北米の顧客SecureVision TechnologiesとのCNC機械加工コラボレーション

クライアントの背景: SecureVision Technologies, シリコンバレーの活気のあるハイテクハブにあります, カリフォルニア, 大手セキュリティテクノロジー企業です。.

Rapideffidictide顧客コラボレーションのケーススタディ – O-Net Technologies Group

Rapideffidictide顧客コラボレーションのケーススタディ: O-Net Technologies Group Co., LTDコラボレーションバックグラウンドO-NETテクノロジー (深セン) Group Co., Ltdは著名です。.

Rapideffidictide顧客コラボレーションのケーススタディ – 深Shenzhen Colibri Technologies

Rapideffidictide顧客コラボレーションのケーススタディ: Shenzhen Colibri Technologies Co., LtdコラボレーションバックグラウンドShenzhen Colibri Technologies Co., Ltdはハイテクです。.

品質を損なうことなく、手頃な価格の機械加工サービス

今日の製造業界での紹介, 品質と信頼性も提供する手頃な価格の機械加工サービスを見つけることが重要です. 全体の企業...