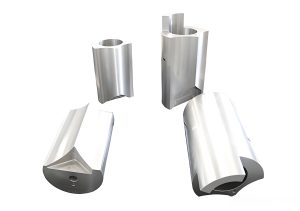

How Does the Content of Impurities in Aluminum Extrusion Parts Affect Their Quality During Processing?

We all know that aluminum extrusions are primarily composed of aluminum, with other metals and non-metals, such as magnesium, manganese,...

Injection Molding Services: The precision manufacturing engine of modern manufacturing

Imagine the rugged case of your smartphone, the complex instrument cluster assembly inside a car, or the component in a...

The Art of Metal Bending: Efficient and Precise Solutions in Manufacturing Services

In the grand scheme of modern manufacturing, metal bending, a seemingly fundamental yet crucial process, acts like a low-key yet...

What factors influence CNC Swiss machining speed?

In modern manufacturing, CNC Swiss machining is an efficient, precise, and flexible process. It can be used to create products...

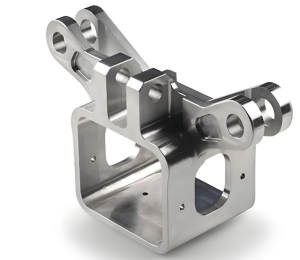

Essential Knowledge for CNC Machining of Precision Parts

We know that the emergence of CNC equipment is a significant milestone in technological advancement. It effectively addresses complex, precise,...

CNC Precision Parts Machining: Selection of Processing Methods and Division of Processes and Work Steps

In modern manufacturing, CNC precision parts machining requires not only high accuracy and excellent surface quality but also efficiency and...

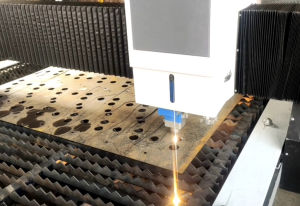

Laser Cutting: The Invisible Blade for Manufacturing Services Upgrades

In the early morning, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system...

A New Benchmark in Efficient Machining: CNC Turning and Rapidefficient’s Manufacturing Revolution

In the arena of manufacturing, time is cost, and precision is life. When traditional machining methods struggle to breathe in...

CNC Thread Machining Methods

Thread machining is one of the most commonly used operations in CNC machining. According to different machining methods, it can...

CNC Aluminum Machining: A Revolution in Efficiency and Precision in Precision Manufacturing

アルミニウム, with its lightweight, high strength, corrosion resistance and excellent electrical and thermal conductivity, has become a core material in...

Types of CNC Machining Datums

To study the relative relationship of part surfaces, a datum must be determined. A datum is a point, line, or...

Choosing Methods for Machining Internal Holes and Surfaces of CNC Lathe Parts

There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning,...

How to ensure the accuracy and stability of parts during processing?

The Significance of Part Accuracy and Stability In the world of manufacturing, especially in CNC machining, the accuracy and stability...

The Truth about the Accuracy of Parts in CNC Machining

The Misconception of Higher Part Accuracy In the field of CNC machining, many people hold a common misconception that the...

Processing technology of shaft parts

Shaft parts are essential components in numerous mechanical and industrial applications. Their proper processing is crucial to ensure the smooth...

The role of nickel plating on aluminum alloy

Aluminum alloy is a widely used material in various industries due to its excellent properties such as lightweight, good conductivity,...

Advantages and disadvantages of CNC machining hardware parts

現代の製造業で, CNC machining has become a crucial process for producing high-quality hardware parts. CNC (Computer Numerical...

How to improve UAV parts processing efficiency and reduce waste

In today’s rapidly evolving technological landscape, unmanned aerial vehicles (UAVs) have become increasingly popular in various fields such as surveillance,...

Precision machining technology and process for mold parts

In the field of manufacturing, precision machining of mold parts plays a crucial role. Mold parts are essential components in...

Sheet metal stamping technology and application

Sheet metal stamping technology is a crucial manufacturing process that has been widely used in various industries. この記事で,...

Challenges and Advances in Irregularly Shaped Parts Processing

Introduction The manufacturing of irregularly shaped parts presents unique challenges to engineers, designers, and manufacturers. Unlike standard geometries, irregular parts...

6 Essential Knowledge Points for Stainless Steel Machining

導入: Stainless steel machining is a critical process in many industries, from aerospace to medical devices. Its high strength, durability,...

Detailed explanation of CNC machining accuracy

1. Introduction to CNC Machining Accuracy CNC (コンピューター数値制御) machining has become one of the most crucial methods of...

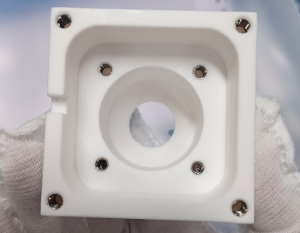

Applications of Teflon Materials in the Machining Industry

導入: Teflon, a brand name for polytetrafluoroethylene (PTFE), has gained widespread popularity in the machining industry due to its exceptional...

How do we address the issue of poor after-sales service for parts?

The manufacturing industry is developing rapidly, and competition in the CNC machining industry is becoming increasingly fierce. Poor after-sales service...

CNC旋盤の機械加工の重要な変更と寸法エラーに対処するための戦略

CNC旋盤の機械加工は、その精度と効率が高いため、現代の製造において重要な役割を果たします. しかし, の変動...

CNCの機械加工小さなバッチとプルーフ効率改善戦略: 新製品開発の進捗状況に一致します

新製品開発の過程で, CNC加工の小型バッチの生産と校正は、しばしばに影響する重要な要因になります。.

CNC加工配信管理を最適化します: 生産計画の効率と調整を改善します

CNCの機械加工の配信の頻繁な遅延は、生産計画の安定性に影響するだけではありません, しかし、コストも増加します。.

顧客のフィードバックと苦情をどのように処理しますか?

CNC処理業界で, 顧客のフィードバックと苦情は、企業がサービスを継続的に改善および強化するための重要な基盤です。.

部品のCNC加工のための最も一般的な欠陥とソリューション

CNC加工は、高精度の製造技術です, しかし、それはまた、いくつかの一般的な機械加工の欠陥に遭遇する可能性があります. これらの欠陥を理解する.

共同ロボット部品のCNC処理プラント

共同ロボット部品は、製造業に革命をもたらしています. これらのロボットは、生産性と効率を向上させるために人間と一緒に機能します. ..で.

インテリジェントな機器部品CNC加工高速ソリューション

1. 今日の高度に発展した製造業での紹介, インテリジェントな機器は、さまざまな分野で重要な役割を果たします. 産業用自動化から...