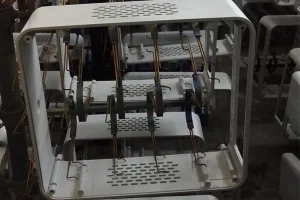

Injection Molding Services: The precision manufacturing engine of modern manufacturing

Imagine the rugged case of your smartphone, the complex instrument cluster assembly inside a car, or the component in a...

The Art of Metal Bending: Efficient and Precise Solutions in Manufacturing Services

In the grand scheme of modern manufacturing, metal bending, a seemingly fundamental yet crucial process, acts like a low-key yet...

What factors influence CNC Swiss machining speed?

In modern manufacturing, CNC Swiss machining is an efficient, precise, and flexible process. It can be used to create products...

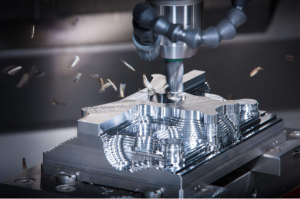

Essential Knowledge for CNC Machining of Precision Parts

We know that the emergence of CNC equipment is a significant milestone in technological advancement. It effectively addresses complex, precise,...

CNC Precision Parts Machining: Selection of Processing Methods and Division of Processes and Work Steps

In modern manufacturing, CNC precision parts machining requires not only high accuracy and excellent surface quality but also efficiency and...

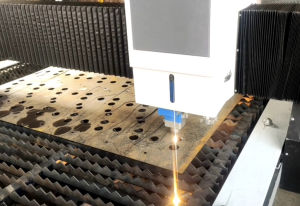

Laser Cutting: The Invisible Blade for Manufacturing Services Upgrades

In the early morning, when engineer Xiao Wang uploaded a complex stainless steel part design drawing to the cloud system...

A New Benchmark in Efficient Machining: CNC Turning and Rapidefficient’s Manufacturing Revolution

In the arena of manufacturing, time is cost, and precision is life. When traditional machining methods struggle to breathe in...

CNC Thread Machining Methods

Thread machining is one of the most commonly used operations in CNC machining. According to different machining methods, it can...

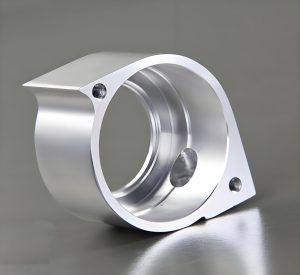

CNC Aluminum Machining: A Revolution in Efficiency and Precision in Precision Manufacturing

アルミニウム, with its lightweight, high strength, corrosion resistance and excellent electrical and thermal conductivity, has become a core material in...

Types of CNC Machining Datums

To study the relative relationship of part surfaces, a datum must be determined. A datum is a point, line, or...

Choosing Methods for Machining Internal Holes and Surfaces of CNC Lathe Parts

There are numerous methods for machining the internal holes and surfaces of CNC lathe parts, including drilling, reaming, boring, turning,...

Six Processes That Can Easily Influence Machining Errors

The slightest carelessness during machine tool processing can lead to errors. Below are six processes that can easily cause machining...

How to charge for sleeve parts processing?

1、Introduction to Sleeve Parts Machining Sleeve parts machining is a crucial process in the manufacturing industry. It involves the shaping...

Cleaning methods and precautions for metal parts processing

1、Introduction to metal parts processing Metal parts processing is a crucial aspect of various industries, playing a significant role in...

CNC Milling Machine: Ideal for Processing Which Parts?

私. Introduction A. Briefly introduce CNC milling machines and their importance in manufacturing. CNC milling machines are highly significant in...

Machining Technology of Connecting Rod Parts

Introduction The Significance of Connecting Rod Parts Connecting rod parts play a crucial role in mechanical systems, especially in engines....

Wire-cut Machining: The Precision Power in CNC Realm

私. Introduction to Wire-cut Machining A. Definition and Basic Principle Wire-cut machining, also known as Wire Electrical Discharge Machining (WEDM),...

Aluminum alloy processing polishing mirror: dazzling surface treatment art

私. Introduction A. Hook the Readers In our daily life and various industries, aluminum alloy products with polished mirror surfaces...

Unveiling the Commonly Used Knives in CNC Machining

Introduction In the world of CNC machining, knives play an absolutely crucial role. They are like the “magic wands” それ...

Analysis of bevel gear processing technology: Manufacturing art of precision transmission

導入:Bevel gear processing technology is crucial in precision transmission. This article explores its details and the value of rapidefficient in...

Application and Development Trend of CNC Milling Machine

私. Introduction to CNC Milling Machine A. Definition and Basic Functions A CNC milling machine, also known as a computer...

Aluminum alloy thin-wall parts processing how to anti-shock knife

私. Introduction The Significance of Aluminum Alloy Thin-Wall Parts Processing Aluminum alloy thin-wall parts play a crucial role in numerous...

What are the capacity indicators of aluminum alloy die-casting processing plants

1、Introduction What is aluminum alloy die-casting processing? Aluminum alloy die-casting processing is a manufacturing method that involves injecting molten aluminum...

Aluminum alloy precision die casting manufacturers how to choose?

1、導入 1. Definition and importance of these manufacturers in the industry. Aluminum alloy precision die casting manufacturers are specialized in...

The Advantages and Applications of CNC Aluminum Machining in Modern Manufacturing

ABSTRACT This paper discusses the importance of CNC aluminum machining in modern manufacturing. It elaborates on the research background and...

Aerospace-Grade Aluminum Machining: Precision in the Skies

1、Understanding Aerospace-Grade Aluminum Machining Aerospace-grade aluminum machining plays a crucial role in the aerospace industry. Aerospace-grade aluminum is a specialized...

CNC Aluminum Machining Tolerances

ABSTRACT This paper provides a comprehensive analysis of CNC aluminum machining tolerances. Key factors determining these tolerances are identified, including...

CNC Aluminum Machining: Unleashing Precision and Efficiency

私. Core Perspectives 1.1 Key Processes Driving Transformations in Manufacturing CNC Aluminum Processing: A Vital Technology in Modern Manufacturing CNC...

CNC Aluminum Prototype Machining: Unleashing Precision and Innovation

一、Understanding CNC Aluminum Prototype Machining (一)What is CNC Aluminum Prototype Machining? CNC aluminum prototype machining refers to the process of...

Research Report on Aerospace CNC Aluminum Machining

1. Core Viewpoints 1.1 Key Manufacturing Technology Driving Aerospace Development Aerospace CNC aluminum machining is of crucial significance in the...

CNC-machined turbine blades: A masterpiece of precision manufacturing

Introduction In the wondrous world of CNC machining, every component is like a meticulously crafted work of art, and the...

High-precision transmission gearbox housing

Introduction In a complex mechanical system, if there is a part that can be like a “caring little housekeeper”, which...

CNC machined aluminum alloy connector: fully supports the core components

Introduction Hello everyone, I’d like to introduce this CNC-machined aluminum alloy connector. Like a meticulous butler, it securely holds all...

高い – Precision CNC – Machined Aluminum Heat Sinks: The “Cool Guardians” for High – Performance Equipment Worldwide

Introduction Hey everyone! Today, I’m taking you on a journey into the fascinating world of a thermal management revolution, そして...

Rapidefficient creates miniature computer case for TechSphere

BackgroundIn June 2024, we partnered with TechSphere in Tokyo. TechSphere, with operations spanning Asia, from the bustling streets of Seoul...

Rapidefficient’s Precision Craftsmanship in Smart Electronic Door Locks for Scandinavian Innovator NordicSafe Solutions

Rapidefficient views every project as a new challenge, and this one was no exception. BackgroundIn early 2023, we partnered with...

Rapideffisitの北米の顧客SecureVision TechnologiesとのCNC機械加工コラボレーション

クライアントの背景: SecureVision Technologies, シリコンバレーの活気のあるハイテクハブにあります, カリフォルニア, 大手セキュリティテクノロジー企業です。.

Rapideffidictide顧客コラボレーションのケーススタディ – O-Net Technologies Group

Rapideffidictide顧客コラボレーションのケーススタディ: O-Net Technologies Group Co., LTDコラボレーションバックグラウンドO-NETテクノロジー (深セン) Group Co., Ltdは著名です。.

Rapideffidictide顧客コラボレーションのケーススタディ – 深Shenzhen Colibri Technologies

Rapideffidictide顧客コラボレーションのケーススタディ: Shenzhen Colibri Technologies Co., LtdコラボレーションバックグラウンドShenzhen Colibri Technologies Co., Ltdはハイテクです。.

品質を損なうことなく、手頃な価格の機械加工サービス

今日の製造業界での紹介, 品質と信頼性も提供する手頃な価格の機械加工サービスを見つけることが重要です. 全体の企業...