Introduction

High Precision CNC machining is revolutionizing the manufacturing industry. With its ability to produce complex parts with exceptional accuracy, it has become the cornerstone of quality in modern production. This article explores the importance of High Precision CNC machining, its benefits, and why it is essential for industries demanding top-tier quality.

What is High Precision CNC Machining?

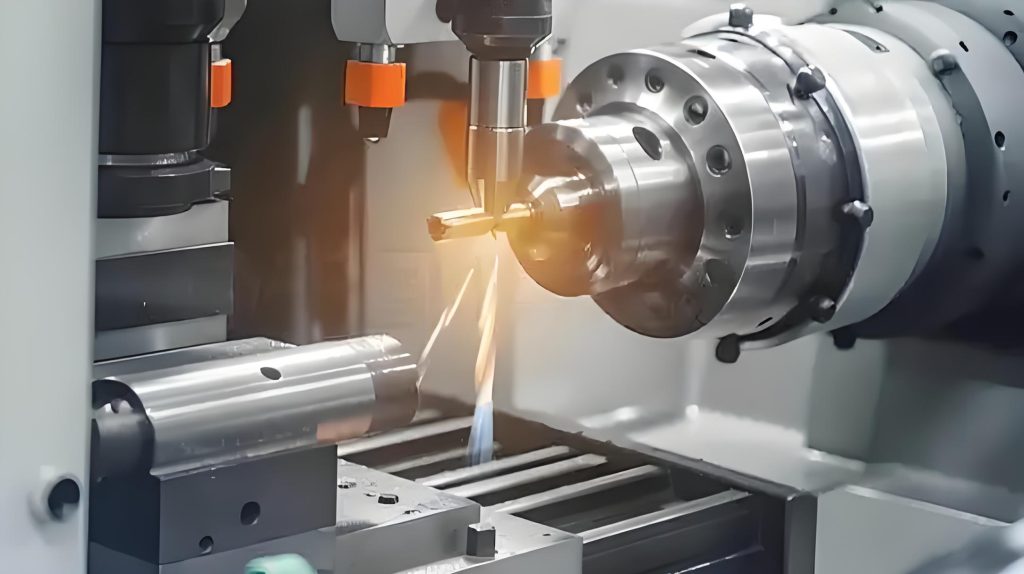

High Precision CNC (Computer Numerical Control) machining is a manufacturing process that uses computerized controls to operate machine tools. It ensures extreme accuracy, often within microns, making it ideal for industries like aerospace, medical, and automotive.

The process involves cutting, drilling, and shaping materials such as metal, plastic, or composites into precise components. High Precision CNC machining is known for its repeatability, consistency, and ability to handle complex geometries.

Why High Precision CNC Machining Matters

Unmatched Accuracy: High Precision CNC machining delivers parts with tolerances as tight as ±0.001 mm. This level of accuracy is critical for industries where even the smallest deviation can lead to failure.

Consistency: Once a design is programmed, CNC machines can produce identical parts repeatedly, ensuring uniformity across large production runs.

Complexity Made Simple: High Precision CNC machining can create intricate designs that are impossible to achieve with manual machining.

Efficiency: Automated processes reduce human error and increase production speed, saving time and costs.

Material Versatility: From aluminum to titanium, High Precision CNC machining works with a wide range of materials, making it adaptable to various industries.

Applications of High Precision CNC Machining

High Precision CNC machining is indispensable in several sectors:

Aerospace: Producing lightweight, durable components for aircraft and spacecraft.

Medical: Crafting surgical instruments, implants, and diagnostic equipment with extreme precision.

Automotive: Manufacturing engine parts, transmission components, and custom fittings.

Electronics: Creating intricate circuit boards and enclosures for devices.

The Role of Rapidefficient in High Precision CNC Machining

In the competitive world of CNC machining, Rapidefficient stands out as a leader. Known for their cutting-edge technology and commitment to quality, Rapidefficient specializes in High Precision CNC aluminum machining. Their services are tailored to meet the demands of industries that require flawless, high-performance components.

Why Choose Rapidefficient?

State-of-the-Art Equipment: Rapidefficient uses advanced CNC machines to ensure the highest level of precision.

Expert Team: Their skilled engineers and technicians bring years of experience to every project.

Fast Turnaround: Rapidefficient prioritizes efficiency without compromising quality, delivering parts on time.

Custom Solutions: Whether it’s prototyping or large-scale production, Rapidefficient offers tailored services to meet unique needs.

Conclusion

High Precision CNC machining is the key to achieving superior quality in manufacturing. Its ability to produce accurate, consistent, and complex parts makes it indispensable across various industries. For businesses seeking reliable and efficient CNC machining services, Rapidefficient is the go-to provider. Their expertise in High Precision CNC aluminum machining ensures that every component meets the highest standards of quality and performance.