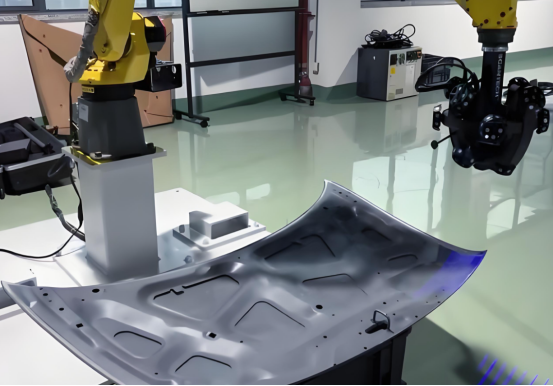

Automotive industry

In the field of automobile manufacturing, stamping sheet metal technology plays an important role and is widely used in the manufacturing of automobile bodies and many parts.

As far as automobile bodies are concerned, stamping sheet metal technology can process pieces of metal sheets into shapes that meet design requirements, such as roofs, doors, hoods, trunk lids and other body coverings. These parts require high dimensional accuracy, flatness and impact resistance. Stamping sheet metal can produce high-strength and lightweight coverings through precise stamping and forming technology. While meeting the above requirements, it realizes the lightweight of parts and reduces the overall weight of the car, thereby improving fuel economy and power performance.

In terms of parts manufacturing, skeleton structural parts such as frames and subframes are used to support and fix various parts of the body. They need to have high strength and rigidity. Stamping sheet metal uses suitable high-strength steel and can produce parts that meet these characteristics after stamping. There are also internal assemblies such as dashboards and seat frames. On the basis of ensuring lightweight, comfort and safety must be taken into account. Stamping sheet metal technology can also play a role in shaping shapes and structures that meet the requirements.

For example, traditional automobile body manufacturing uses sheet metal stamping + welding technology. Although Tesla first used aluminum alloy die-casting technology to die-cast the rear structural parts of the car body in one piece in Model Y, it also relied on stamping sheet metal technology to create many key components. The stamping sheet metal process plays an extremely critical role in the overall performance and appearance of the car. It is one of the indispensable processing technologies in automobile manufacturing and has strongly promoted the development of the automobile industry.

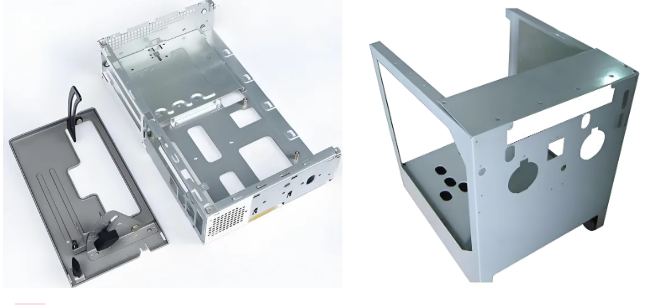

Electronic and electrical industry

In the electronic and electrical industry, stamping sheet metal is also an indispensable component and is widely used in many products such as computer cases, mobile phones, and MP3s.

Take the computer case as an example. As an important bearing component of computer hardware, it needs to have a certain strength to protect the various electronic components inside. At the same time, it also has high requirements for the accuracy and aesthetics of the appearance. The chassis shell made by the stamping sheet metal process not only meets the strength standards, but also can ensure the dimensional accuracy of each surface of the shell through precise cutting, bending, punching and other processes, and the joints are tightly connected and the appearance is exquisite.

For mobile phones, the internal sheet metal structure plays a role in supporting and protecting key components such as the motherboard and battery under the small and light appearance. The stamping sheet metal process can process metal sheets into various shapes to meet the compact internal space layout requirements of mobile phones. In addition, its good conductivity can also be used for electromagnetic shielding to prevent external electromagnetic interference from affecting the normal operation of mobile phones and ensure the stable performance of mobile phone communication, computing and other functions.

Looking at small electronic devices such as MP3, the exquisiteness and dimensional accuracy of the shell directly affect the quality and user experience of the product. The stamping sheet metal process can accurately create a shell that meets the design requirements, so that it can meet the function of protecting internal components while making the appearance more attractive, which meets the public’s dual pursuit of beauty and practicality of electronic and electrical products, and fully reflects the important value of stamping sheet metal in meeting the requirements of product accuracy and appearance.

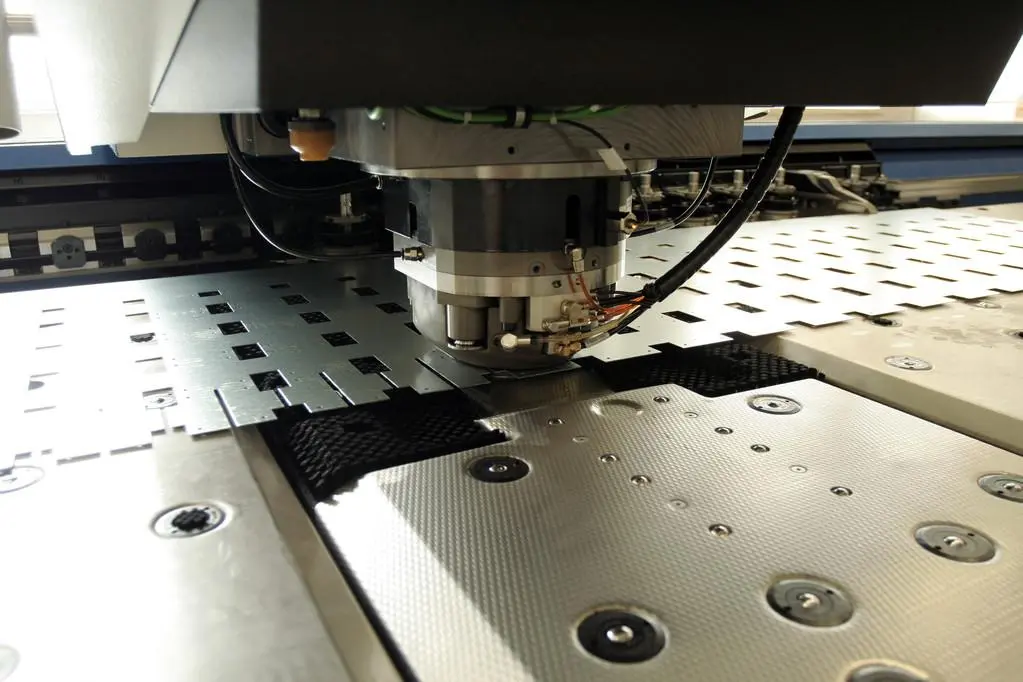

Other industries such as construction, aerospace

The application range of stamping sheet metal is very wide, and it has important applications in the construction industry and aerospace industry.

In the construction industry, stamping sheet metal is often used to manufacture components such as doors, windows, and railings. For example, the frames of doors and windows can be processed into suitable shapes and sizes through the stamping sheet metal process to ensure their structural strength, so that they can be installed on buildings for a long time and stably, playing the role of separation, protection and lighting. For the railing part, whether it is indoor decorative railings or outdoor protective railings, the stamping sheet metal process can produce a variety of beautiful, sturdy and durable railing styles to meet the needs of different architectural styles and usage scenarios.

In the aerospace industry, stamping sheet metal plays a key role. In aircraft manufacturing, the manufacture of large structural components such as fuselages and wings is inseparable from the stamping sheet metal process. Most aircraft use thin-walled sheet metal materials. At the same time, in order to reduce the resistance of the aircraft during flight, these materials are mostly processed into streamlined skins to wrap the fuselage, wings and other parts. The stamping sheet metal process can perform precise cutting, bending, and forming operations on sheet metal materials to produce complex-shaped components that meet aerodynamic requirements and meet the strict requirements of the aerospace field for lightweight and high strength. For example, in the processing and manufacturing of launch vehicle fairings, 2A12 aluminum alloy materials are processed by stamping-related processes such as mirror-image stretching forming processes. The fairings produced have a high-precision profile, and wrinkles on the surface of the components are avoided, which greatly improves the quality of the components and makes them stable.

In addition, in the manufacturing of structural components of spacecraft such as satellites, stamping sheet metal can also create various high-precision and high-strength parts that meet the use of space environments according to design requirements, fully demonstrating the wide range of its application and providing strong technical support for the development of different industries.

Summary

The stamping sheet metal process shines brightly in the modern manufacturing industry with its unique charm and wide application. If you have business needs in related fields or are interested in stamping sheet metal processes, please feel free to contact us. We have a professional team, advanced equipment and rich experience, and can provide you with high-quality stamping sheet metal solutions to help your project succeed.