Prototypes belong to the processing and customization industry. They are mainly used for verification and submission during the development of new products. They play a key role in the product development process. They are mainly to find out the appearance defects of the product and avoid problems in the later batch production process. The prototype model industry can process soft plastics, rubber and metal materials. The common materials for prototype models are as follows:

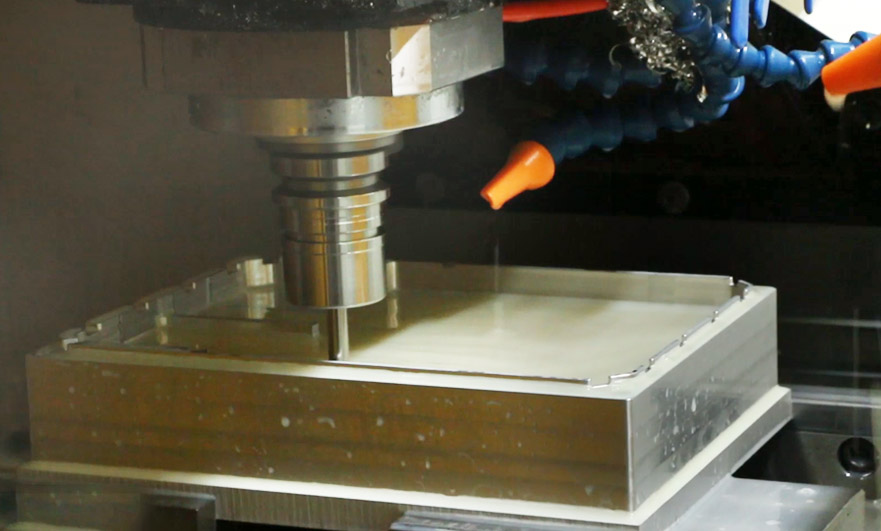

Aluminum alloy: Aluminum alloy is a common material for hardware prototypes in prototype factories. It has good strength and hardness. 5052, 6063, 6061, and 7075 series of aluminum alloys are used most. The appearance of aluminum alloy prototypes is generally sandblasted oxidation or electroplating.

Stainless steel: The common materials for stainless steel prototypes are SUS304, 316. Stainless steel prototypes have high strength and good corrosion resistance; stainless steel iron has a magnetic attraction and is used for special parts.

ABS: ABS material has good impact resistance, strength, toughness and temperature resistance. It is easier to disassemble and process, and it is also easier to glue. Many types of prototypes require ABS.

PC: good strength, good toughness, impact resistance, high temperature resistance, good insulation, the material itself is translucent. It can also be dyed and sprayed. It is the first choice for transparent or translucent prototypes.

Acrylic: also called plexiglass, with the best transparency. The disadvantage is that it is brittle and easy to crack.

TPE/TPU: used to make soft rubber hand pads. Silicone keyboard remote control hand pads are more used in areas such as 30-90 degrees.

POM: high hardness, smooth surface, high density, very wear-resistant, very suitable for some gear palms.

PP: PP material is relatively light, elastic, and temperature resistant to about 100 degrees. Low-pressure infusion is widely used, mainly for large automotive parts, front and rear bumpers, center consoles, or shells in the medical industry.

Nylon: Nylon has high strength and good wear resistance. The disadvantage is that it is not easy to glue. Large materials are generally not selected because they cannot be disassembled.