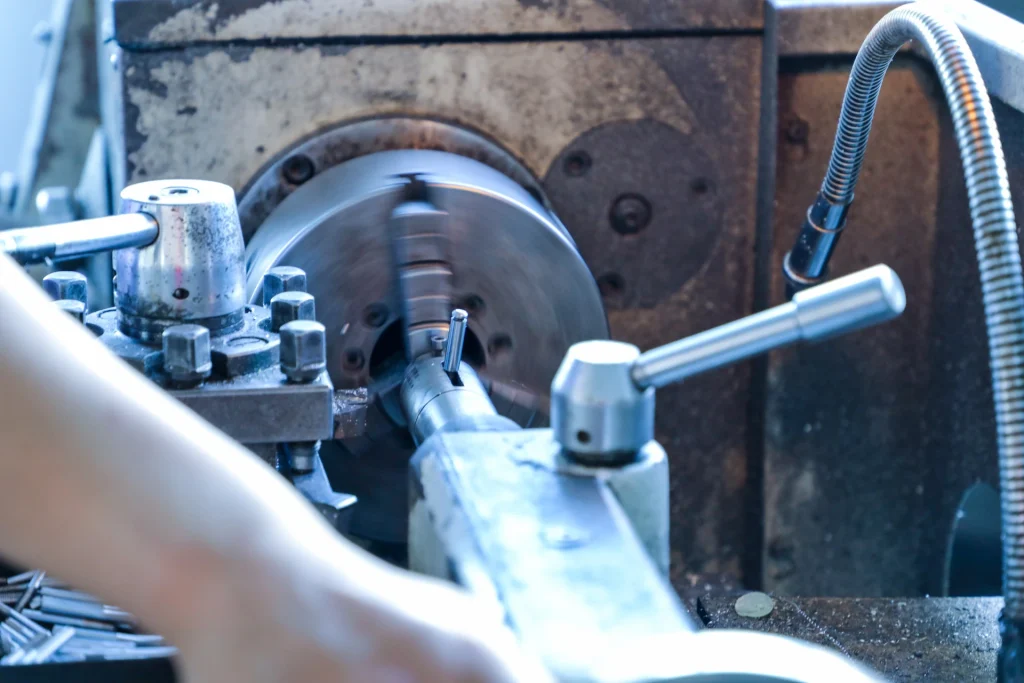

In the precision arena of modern manufacturing, CNC (Computer Numerical Control) precision parts machining plays an irreplaceable central role. It is not only synonymous with high-end manufacturing but also a key bridge to transform design blueprints into physical products with seamless and excellent performance. Especially in fields where precision is almost demanding

–

aerospace, precision medical devices, optical instruments, cutting-edge electronic devices

–

CNC machining is the core technical guarantee for achieving complex designs with its unparalleled precision, excellent repeatability and high flexibility.

What is the secret of micron-level accuracy?

The core charm of CNC precision machining lies in its ultimate precision beyond human hands:

1. Digital Precise Instructions: The machining process is entirely driven by computer-generated precision programs (G-codes), completely eliminating manual operation errors.

2. Rigid Cornerstone: The highly rigid machine tool structure and precision guide/lead screw provide strong support for stable machining and resist deformation caused by cutting forces.

3. Closed-loop precise control: Servo motors are equipped with high-resolution encoders to monitor and dynamically adjust tool positions in real-time, with accuracy reaching microns (μm) or even sub-micron.

4. Advanced Tool Blessing: Ultra-hard, ultra-wear-resistant tools (such as diamond, CBN-coated tools) and micro-diameter tools ensure fine cutting and long life.

5. Strict environmental control: Constant temperature workshop and high-efficiency shock absorption system minimize the impact of environmental thermal deformation and vibration on accuracy.

Master of shaping complex geometry

CNC technology, especially multi-axis (5-axis, turn-milling) machining centers, gives engineers unprecedented design freedom:

Complex Surface Engraving: Effortlessly navigate parts with highly complex surface features such as impellers, turbines, and complex mold cavities.

One-time clamping, multi-sided forming: Reduces the number of clamping times, significantly improving overall accuracy and efficiency, and reducing the risk of cumulative errors.

Deep Cavity Microporous Challenger: Precision tools with high-speed spindles can deeply process deep cavities, micro holes, and precise internal features.

Special-shaped problem solver: Easily handle the processing of special-shaped parts that are difficult to achieve with traditional methods.

Core Support in a Wide Range of Fields

Aerospace: Engine core blades, combustion chamber precision components, lightweight and high-strength structural parts, related to flight safety and performance.

Medical technology: artificial joints (hip joints, knee joints), precision surgical instruments, implants, and high-resolution endoscopic components, which are directly related to life and health.

Precision optics: Lens barrels, laser core components, and complex mirror holders require nanoscale surface finish and shape and position accuracy.

Semiconductor manufacturing: Key components of wafer processing equipment and precision parts of vacuum chambers to ensure the purity and precision of chip manufacturing.

High-end Cars: Fuel injection systems, turbocharger precision components, and high-performance drivetrain components enhance power and efficiency.

The Value of Choosing a Professional Partner

Faced with the need for high-precision and high-complexity parts, it is crucial to choose an experienced CNC precision machining partner. The professional processing plant not only has top-notch equipment, but also has:

Deep process accumulation: Optimize cutting parameters for different materials (titanium alloys, superalloys, ceramics, medical stainless steel, etc.).

Precision Testing Assurance: Equipped with high-precision testing equipment such as coordinate measuring machine (CMM), roundness meter, roughness meter, etc., to ensure 100% qualified delivery.

Rigorous quality management: A complete quality control system (such as ISO 13485 medical device certification) throughout the whole process to ensure stable and reliable products.

Engineering Collaborative Capabilities: Design for Early Intervention (DFM) to optimize manufacturability, reduce costs, and shorten cycle times.

Epilogue

CNC precision parts machining is an indispensable cornerstone of modern high-end manufacturing. It uses digital and automated methods to achieve precise control in the micron-level world, transforming cutting-edge design concepts into physical products with excellent performance. Whether it is an aircraft soaring in the sky, a medical device that protects health, or a chip that drives the future, behind it is the exquisite craftsmanship and unremitting pursuit of CNC precision machining technology. Choosing a professional CNC precision machining partner means choosing a solid guarantee of quality, reliability and continuous innovation, which is the key technical foundation to win the future in the fierce competition.