Thread machining is one of the most commonly used operations in CNC machining. According to different machining methods, it can be divided into tapping, thread milling, and thread turning (pick-and-tap method). The following describes these methods in detail.

1. Tap Processing (Tapping)

Tapping is the most common method, generally suitable for small-diameter internal thread holes (D < 30 mm).

(1) Rigid Tapping

- Directly driven by the spindle feed, with high efficiency and precision.

- It is currently the mainstream CNC tapping method.

(2) Flexible Tapping

- The feed and spindle are not strictly synchronized.

- It requires a floating chuck to compensate for feed errors.

- Less efficient and less precise than rigid tapping.

Bottom hole diameter selection:

For example, for an M8 thread, the bottom hole drill bit diameter is Ø6.8–Ø6.9 mm. Choosing the upper limit (Ø6.9 mm) can reduce the cutting load on the tap.

Tap selection:

- Through holes → spiral-point tap.

- Blind holes → spiral-flute tap.

2. Thread Milling

Thread milling uses a rotating tool to cut threads, suitable for larger holes and materials that are difficult to machine.

Advantages:

- High efficiency, especially for larger threads.

- The same tool can machine left-hand and right-hand threads.

- Convenient chip evacuation, reducing risk of tool breakage.

- Particularly suitable for difficult-to-cut materials.

Programming note:

Thread milling requires helical interpolation. Different CNC systems (Fanuc, Siemens, etc.) may use slightly different parameter codes, so programming should follow the machine tool’s documentation.

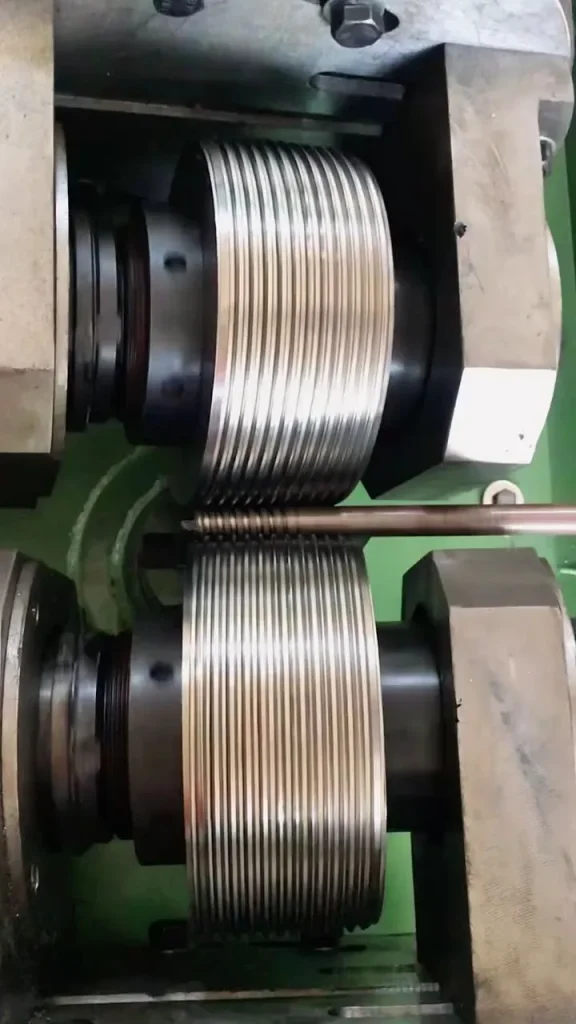

3. Thread Turning (Pick-and-Tap Method)

Thread turning is carried out on a CNC lathe, suitable for machining external and internal threads of larger diameters.

- By using a single-point tool, threads are cut gradually.

- It is an alternative when special taps or thread milling cutters are not available.

4. Summary

The main methods of CNC thread machining are:

- Tapping → efficient for small-diameter holes.

- Thread milling → flexible, efficient, suitable for large or special threads.

- Thread turning (pick-and-tap method) → suitable for larger threads or when special tools are unavailable.

Each method has its own advantages and limitations. The choice depends on the thread size, material, and machining conditions.

About RapidEfficient

RapidEfficient specializes in high-precision CNC machining with 18 years of experience. Its products cover medical, communications, optics, drones, intelligent robots, automotive and office automation parts.

The company’s CNC machining centers include four-axis, five-axis and linkage machine tools, and are equipped with precision projectors, three-coordinate measuring machines, spectrometers and other precision testing equipment.

- Machining accuracy: up to 0.01mm

- Testing accuracy: up to 0.001mm