In a traditional CNC shop, the operator repeats the process day after day: lifting the heavy blank onto the table, starting the program, monitoring the machining process, then laboriously unloading the finished product, cleaning up debris, changing tools… Sweat soaks the tooling, energy is consumed in repetitive labor, but the core value of precision machining is difficult to fully release. This has been a true portrayal of countless workshops.

At the heart of CNC machining lies the precision charm of its digital control. According to the precise instructions generated by the CAD model, the CNC machine tool drives the tool to perform high-speed, high-precision material cutting in three-dimensional space, completing the machining from complex surfaces to precise holes. However, in the traditional model, operators invest a lot of time in loading and unloading, inspection, tool change, etc., and the valuable production capacity of the machine tool is often wasted in waiting, becoming a bottleneck that restricts efficiency.

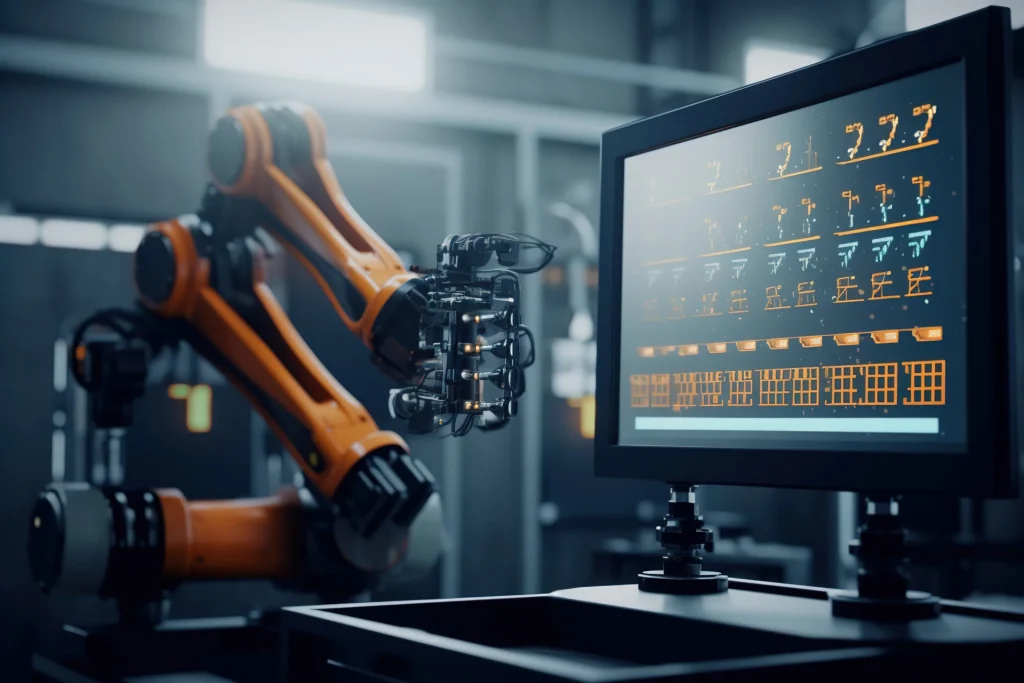

The infusion of automation and robotics has brought a revolutionary pulse to CNC machining:

1. The Tireless “Porter”: Robotic Unloading and Unloading

With its precise, tireless characteristics, industrial robots are perfectly qualified for the heavy task of blank loading and finished product blanking. They can work continuously 24 hours a day, seamlessly connect different processes, completely eliminate the “window period” of machine tools, and push equipment utilization to the limit. With the blessing of the vision system, the robot can intelligently identify the position and posture of the workpiece, adapt to changes, and greatly improve its flexibility.

2. Smart “Eyes” and “Hands”: Integrated Inspection and Flexible Assembly

The automation system embeds the online inspection link in the processing process. High-precision sensors act as keen eyes, monitoring workpiece dimensions, surface finishes, and even tool wear status in real time. Once an abnormality is found, the system immediately alarms or automatically compensates and adjusts to nip the scrap rate in the bud. The robot arm can also perform precision assembly tasks after processing, realizing the integration of “machining-assembly” on the CNC platform, shortening the process and improving product consistency.

3. Precise “Butler”: Full Lifecycle Management of Tools

An automated tool management system is like a savvy steward. It automatically identifies, grabs, loads, and unloads tools, and accurately measures tool length and diameter compensation values. The system monitors tool life in real-time, predicts wear, and automatically replaces at critical moments, ensuring consistent machining quality while optimizing tool inventory and reducing waste.

4. The “Guardian” of Cleaning: Automated Deburring and Cleaning

After machining, burr cleaning and cleaning can now also be done efficiently by special automation equipment or robots. They perform consistent, consistent movements to ensure that each workpiece achieves the required cleanliness and surface quality, freeing up manpower from complex labor.

5. The “nerve center” of data: system integration and intelligent decision-making

At the heart of modern automated CNC units are powerful integrated control systems such as MES/MOM. It acts as a nerve center, coordinating the operation of robots, machine tools, testing equipment, and logistics systems to achieve smooth instruction flow and data flow. The system collects and analyzes processing data (such as vibration, temperature, and power) in real time to provide data support for predictive maintenance, process optimization, and production scheduling, driving decision-making from experience to intelligence.

Automation technology is not a cold machine replacement, but a new paradigm of human-machine collaboration. Operators are freed from repetitive, heavy manual labor, and their roles transform into system monitors, program optimizers, exception handling experts, and data analysts. They focus on higher-value tasks: optimizing process parameters, analyzing machining data for continuous improvement, responding quickly to complex anomalies, and maintaining and upgrading automated systems. Human intelligence and machine power are combined at a higher level.

Automation and robotics are reshaping the field of CNC machining with unprecedented force, driving the profound transformation of traditional workshops into smart factories. In the precise pulse of machines, human intelligence can be sublimated from complex labor to focus on higher-value creation and decision-making – this is not a cold replacement, but a new prologue to human-machine collaboration. When automation technology becomes the “standard” rather than “optional” of CNC machining, the wave of intelligent manufacturing will surely sweep the entire manufacturing landscape, in this change, whoever can take the lead in embracing the unlimited potential given by automation, who can play the strong voice of the future industry in a more efficient, intelligent and sustainable way on the stage of precision manufacturing.