Precision hardware parts processing

Serve

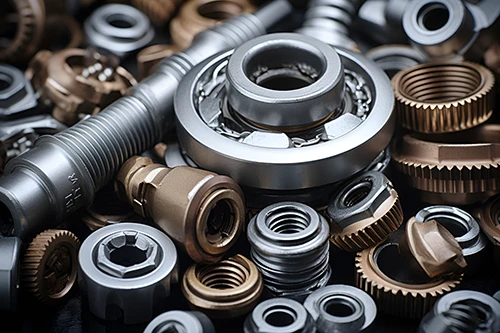

Precision hardware parts refer to high-precision, Metal parts with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and machinery, Plays a key role in product performance and quality.

One-off CNC machining prototype

Our precision hardware parts processing capabilities

Choose Rapidefficient Precision Hardware Parts, The reasons are as follows: First, high precision, Able to meet high requirements on part size and shape, Ensure precise product fit and performance. Second, high production efficiency, Advanced manufacturing processes and technologies enable rapid mass production, Shorten delivery cycle. Third, reliable quality, Using high-quality materials and strict quality control, Parts have good durability and stability. Fourth, it can be customized, Parts with complex shapes and structures can be customized according to different needs. In short, It is ideal for many high-end manufacturing areas.

Choose Rapidefficient Precision Hardware Parts, The reasons are as follows: First, high precision, Able to meet high requirements on part size and shape, Ensure precise product fit and performance. Second, high production efficiency, Advanced manufacturing processes and technologies enable rapid mass production, Shorten delivery cycle. Third, reliable quality, Using high-quality materials and strict quality control, Parts have good durability and stability. Fourth, it can be customized, Parts with complex shapes and structures can be customized according to different needs. In short, It is ideal for many high-end manufacturing areas.

Precision hardware parts refer to high-precision, Metal parts with high complexity and strict quality requirements. They are commonly used in a variety of precision equipment and machinery, Plays a key role in product performance and quality.

Precision hardware parts can be classified according to their functions and uses, Mainly includes connecting parts, Transmission parts, Support parts, etc., connecting parts such as bolts, nut, Rivets etc., For connecting different parts; Transmission parts such as gears, rack, Lead screw, etc., Used to transmit power and movement; Support parts such as bearing seats, Bracket, Shell etc., Used to support and protect other parts.

Common precision hardware parts processing methods include CNC processing, stamping, casting, forging, EDM, etc.

Electronic equipment hardware

Good at producing mobile phones, Precision hardware casings for computers and other electronic equipment, Connectors, etc., High precision, Excellent quality.

Automobile hardware accessories

Manufacturing car engines, Hardware parts for chassis and other parts, Wear resistance, High strength.

Medical equipment hardware

Production of precision hardware structural parts for medical instruments, Meet strict hygiene standards.

Aerospace hardware

Providing high strength to the aerospace industry, High precision hardware parts.

Precision mold hardware

Good at making hardware accessories in molds, Guarantee mold accuracy and life.

Communication equipment hardware

Production of hardware casings and internal structural parts for communication equipment, Signal is stable.

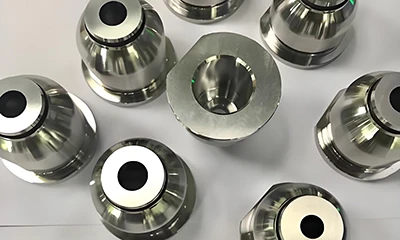

The display of precision hardware parts is stunning. High precision screws, Nuts and other fasteners, Exquisite gears, Shaft parts, Smooth as a mirror. Complex and exquisite structure, Reflect advanced manufacturing technology, Applicable to multiple high-end fields, Highlight the beauty of technology and craftsmanship.

High dimensional accuracy, Ensure precise fit with other components, Improve overall product performance.

Material is hard, Can withstand large external forces, Ensure products operate stably in harsh environments.

Corrosion resistant, Wear-resistant, Long service life, Reduce product maintenance costs.

Understand the uses and needs

Clarify the specific role of precision hardware parts in products, Determine the required accuracy, strength, Corrosion resistance and other performance requirements. For example, in electronic devices, High-precision connection parts may be required to ensure stable signal transmission; in mechanical equipment, High-strength transmission parts may be required to withstand larger loads.

Choose the right material

Common precision hardware materials include stainless steel, Aluminum alloy, Copper etc., Stainless steel has good corrosion resistance and strength; Aluminum alloy is lightweight, Good thermal conductivity; Copper has excellent electrical conductivity. Choose appropriate materials according to specific application scenarios, Also consider cost factors.

Design and processing

1. Consider part manufacturability when designing, Avoid overly complex shapes and structures. Reasonable design tolerances, Ensure parts fit smoothly during assembly.

2. Choose a professional processing manufacturer, They usually have advanced processing equipment, Such as CNC machining center, EDM machine, etc., Processing parameters must be strictly controlled during processing, Ensure dimensional accuracy and surface quality.

Quality inspection

1. Strict quality inspection of precision hardware parts, Includes dimensional measurements, Appearance inspection, Hardness test, Material composition analysis, etc.

2. Use high-precision testing equipment such as three-dimensional coordinate measuring machines, Ensure the dimensional accuracy of parts meets requirements.

Surface treatment

Surface treatment of parts as required, Such as electroplating, Spray, Oxidation, etc., To improve the corrosion resistance of parts, Aesthetics and wear resistance.

Packaging and storage

1. Use appropriate packaging, Protect parts from damage during shipping and storage.

2. Storage environment should be dry, clean, Avoid parts getting wet, Rusted or otherwise contaminated.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

Dimensional deviation: Actual production part size does not match design size

Reason: Insufficient accuracy of processing equipment, Tool wear, Improper setting of process parameters, etc.

Solution

Regular inspection and maintenance of processing equipment, Ensure equipment accuracy.

Replace worn tools promptly, Choose the right tool type and size.

Optimize process parameters, Continuous adjustment through trial processing, to achieve optimal dimensional accuracy.

Surface quality issues: Scratches appear on the surface of the part、glitch、Rust spots, etc.

Reason: Improper operation during processing, Inappropriate tool selection, Poor storage environment, etc.

Solution

Standardize processing operation procedures, Avoid surface damage caused by human factors.

Choose appropriate tools based on part material and processing requirements, Improve the quality of machined surfaces.

Improve storage environment, Take anti-rust measures, Such as applying anti-rust oil, Use rust-proof packaging, etc.

Insufficient strength: Parts are prone to breakage or deformation during use

Reason: Improper material selection, The heat treatment process is unreasonable, There are defects in the design structure, etc.

Solution

Reasonable selection of materials, Select hardware materials with appropriate strength according to the use requirements of the parts and the working environment.

Optimize heat treatment process, Improve material hardness and strength.

Optimize the design structure, Avoid stress concentrations, Improve the overall strength of the part.

Assembly issues: Parts do not fit together smoothly during assembly,The gap is too large or too small, etc.

Reason: Inaccurate dimensional tolerance control, Processing accuracy is not enough, Unreasonable assembly process, etc.

Solution

Strictly control dimensional tolerances, Improve machining accuracy, Ensure fit accuracy between parts.

Optimize assembly process, Use appropriate assembly tools and methods, Ensure the assembly process runs smoothly.

Fully consider assembly requirements during the design phase, Properly design the size and shape of parts, to facilitate assembly.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.