Wrap injection molding

Serve

Overmolding is an advanced manufacturing technology, It combines traditional injection molding and coating technology, By incorporating soft materials such as cloth into the injection molding process, Leather or film wrapped on a hard plastic substrate, Form composite products with specific appearance and functionality.

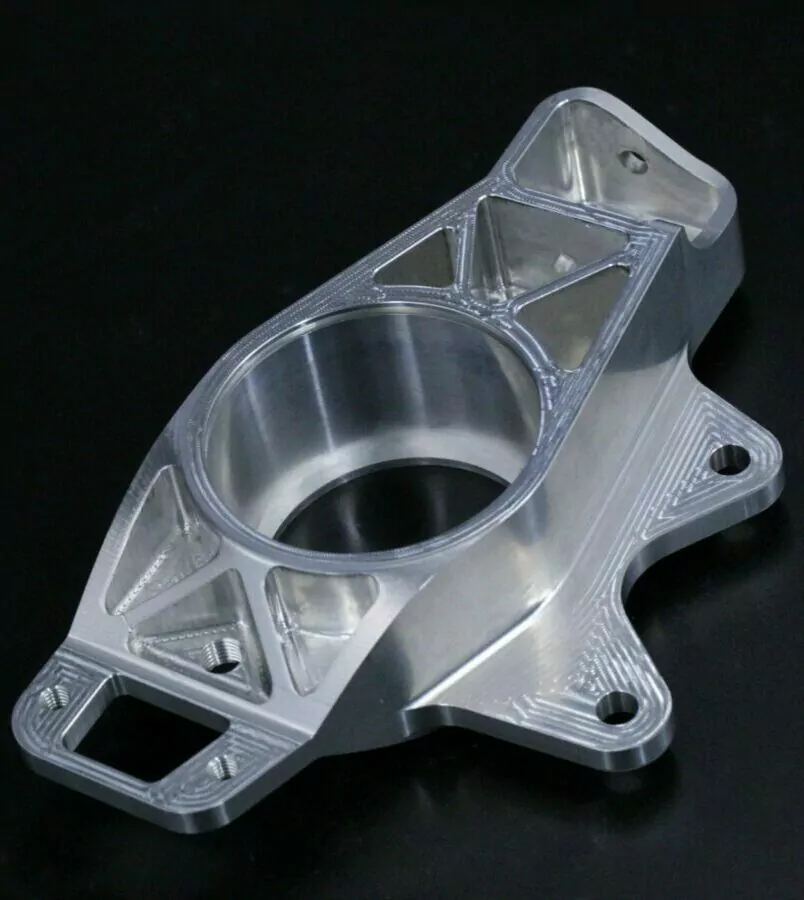

One-off CNC machining prototype

Bond firmly

Flexible design

Efficient production

Our overmolding capabilities

We have an experienced, Skilled R&D and production team, Team members have been working in the plastic mold industry for many years, Familiar with various over injection molding processes, able to quickly, Accurately solve various problems encountered during the production process.

Overmolding is an injection molding process that combines two or more different materials.

During the overmolding process, A material is first injection molded into the base part, Another material, usually one with specific performance or appearance requirements, is then injection molded onto specific areas of the base material, Cover it tightly on the surface or part of the surface of the base material.

1. Closely combined

through precise process control, Can form a strong bond between different materials, Avoid delamination during use, Problems such as falling off.

2. Functional integration

Possibility to combine the advantages of different materials, For example, using hard engineering plastics as a base to provide strength, Then covered with soft elastomer material to increase slip resistance, Shock absorption and other functions.

3. Flexible design

Can be based on different needs of products, Choose from different material combinations and cladding methods, Enable complex shape and structure designs, Meet diverse market needs.

Auto parts field

Automotive interior parts:

Such as the panel of a car center console, By coating a plastic base with a material that has a soft touch and good appearance, Not only improves the aesthetics of the interior, Increased tactile comfort, At the same time, it can also meet the wear resistance requirements of automobile interior parts, Light resistance, Performance requirements such as resistance to temperature changes.

Electronic products field

Mobile phone cases and accessories:

Mobile phone casings can be overmolded, Combines a hard plastic shell with a soft rubber or silicone material, While providing the overall structural strength of the mobile phone, Improve grip feel, And it provides a certain buffering protection when the phone is accidentally dropped.

Medical equipment field

Medical instrument housing:

Housings for some portable medical testing equipment, Over-injection molding can be used to coat the surface of the shell with antibacterial materials or materials with good chemical stability. Ensure that equipment does not contaminate patients or test samples during use, At the same time, it meets the needs of medical equipment that is easy to clean, Disinfection resistance and other requirements.

Household products field

Furniture accessories:

Chair and sofa armrests, Use over-injection molding to cover the armrest surface with soft leather or fabric material, Not only increases the beauty of the furniture, Also provides comfortable support and feel, Make people more comfortable when using furniture.

Sports equipment field

Fitness equipment handles and grips:

like dumbbells, The handle part of fitness equipment such as barbells, Use overmolding to incorporate non-slip, Sweat-absorbent material covers the surface, Can improve the user’s grip strength and stability during exercise, Reduce slippage caused by sweaty hands, It can also reduce hand fatigue and discomfort.

Packaging field

Cosmetic packaging:

Cosmetic bottle cap or part of the bottle body, Through over-injection molding, special textures (such as metallic textures) can be added. matte texture) material, Improve the grade and appearance appeal of cosmetic packaging, It also ensures the sealing and durability of the packaging.

Various exquisite over-injection molded parts are placed on the display table. Has car door handle, The outer soft rubber material not only provides a comfortable grip, Also enhanced anti-slip performance. Colorful mobile phone protective cases, Hard plastic base combined with soft silicone covering, Both fall-resistant and beautiful. There are also handles for medical equipment, Special covering material ensures comfort and hygiene during operation. These parts demonstrate the benefits of overmolding, Achieving the unity of function and beauty.

1. Combining the advantages of different materials: Materials with different properties can be combined, Such as coating hard plastic with soft rubber or elastomer, Make the product have the strength and rigidity of plastic, It has rubber anti-slip, Shock absorption and other properties.

2. Improve durability: By choosing the right cladding material, Can enhance the wear resistance of products, Corrosion resistant, Impact resistance and other properties, Extend product life.

1. Rich appearance effects: A variety of colors can be achieved, A combination of texture and gloss, Make the product more beautiful, Unique appearance, Improve product market competitiveness.

2. Hide imperfections: For some products with higher appearance requirements, Overmolding can mask surface defects in the base material, Improve the overall quality of your product.

1. Integrated molding: Overmolding can integrate multiple parts into one piece, Reduced assembly process, Improved production efficiency, Reduced production costs.

2. High degree of automation: Suitable for mass production, Can use automated production equipment, Improve production stability and consistency.

Product planning stage

1. Clarify needs:

Determine product functionality, Performance requirements and appearance expectations. For example, Is it necessary to be anti-slip, damping, Waterproof and other characteristics, and color, Texture specific requirements.

Consider the product’s usage environment and target market, to choose the right combination of materials.

2. Design feasibility analysis:

Evaluate whether a product’s structural complexity is suitable for overmolding. Check if there are any areas that are difficult to achieve coverage, such as too deep a groove, Sharp corners, etc.

Communicate with engineers and moldmakers, Make sure the design is technically feasible, and understand possible manufacturing constraints and challenges.

Material selection stage

1. base material:

Choose a strong enough, Base material for stiffness and heat resistance, to support the entire product structure. Common base materials include engineering plastics, ABS, PC etc.

Consider the compatibility of base and cladding materials, Make sure the two work well together.

2. Covering material:

Choose appropriate coating materials according to the functional requirements of the product. For example, For products that require anti-slip, rubber or elastomer materials can be selected; For products that need to be beautiful, plastic materials with special textures or colors can be selected.

Consider the fluidity of the cladding material, Properties such as shrinkage and hardness, To ensure that the base material can be evenly covered during the injection molding process.

Mold design stage

1. Parting surface design:

Reasonable design of parting surface, Ensure that the product can be smoothly released from the mold, At the same time, avoid obvious marks on the parting surface.

For overmolding, The design of the parting surface should consider the flow direction and filling method of the cladding material, To ensure the quality of the cladding layer.

2. Gate location selection:

Determine the appropriate gate location, To ensure that the plastic can evenly fill the mold cavity. For overmolding, The gate location should be selected to allow the coating material to fully flow and evenly cover the base material.

Consider gate type and size, To control the flow speed and pressure of plastic, Avoid spraying, Defects such as flow marks.

3. Cooling system design:

Design an effective cooling system, To ensure that the product can be cooled quickly after injection molding, Shorten production cycle. For overmolding, The cooling system should consider the cooling needs of both the base material and the cladding material, Avoid product deformation or dimensional deviation due to uneven cooling.

Injection molding process parameter setting stage

1. temperature control:

Set the appropriate injection temperature, Includes melting temperatures of base material and cladding material. Excessive temperatures may cause the material to decompose or discolor, If the temperature is too low, it may affect the fluidity and filling performance of the material.

Control mold temperature, To ensure the cooling speed and quality of the product. For overmolding, Mold temperature control is particularly important, Because it will affect the bonding strength between the coating material and the base material.

2. Pressure and speed control:

Adjust injection pressure and speed, To ensure that the plastic can fully fill the mold cavity, and avoid short shots, Defects such as flash edges. For overmolding, Pressure and speed parameters need to be optimized based on the properties of the cladding material and product structure.

Control holding pressure and time, to compensate for the shrinkage of the plastic during cooling, Ensure product dimensional accuracy.

3. time control:

Determine the appropriate injection molding time, Cooling time and demoulding time. Injection molding time should be long enough, To ensure that the plastic fully fills the mold cavity; Cooling time should be determined based on the size and material properties of the product, To ensure that the product is fully cooled; The demoulding time should be carried out after the product has cooled to sufficient strength, Avoid deformation or damage.

Appearance inspection

1. Appearance inspection:

Check the appearance quality of the product, including color, Glossiness, Does the texture meet the requirements, and whether there are surface defects such as flow marks, bubble, Sink marks, etc.

For overmolding, In particular, check the uniformity of the cladding and the strength of the bond, Make sure there is no delamination or peeling.

2. Dimensions:

Use measuring tools to accurately measure product dimensions, Ensure product dimensional accuracy meets design requirements. for key dimensions, Strict control and testing should be carried out.

Consider material shrinkage and deformation factors, Make appropriate compensations and adjustments during the design and production process.

3. Performance testing:

Performance testing based on product functional requirements, Such as mechanical property testing (tensile, bending, impact, etc.) Heat resistance test, Corrosion resistance test, etc.

For overmolding, The bonding strength of the cladding to the base material should also be tested, And the performance stability of the product under different environmental conditions.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

Poor bonding between cladding layer and base material

Performance: The cladding peels off easily from the substrate, Weak binding force.

reason: Improper material selection, Injection molding process parameters are inappropriate, Unreasonable mold design, etc.

Surface defects

Performance: Flow marks appear, bubble, Surface problems such as sink marks.

reason: Injection molding speed is too fast or too slow, Uneven temperature, Unstable pressure, Rough mold surface, etc.

Dimensional deviation

Performance: Product size does not match design requirements, Tolerance out of range.

reason: Mold manufacturing accuracy is not high, Injection molding process parameters are unstable, Changes in material shrinkage, etc.

Color difference

Performance: The color of the cladding layer is inconsistent with the base material, Or there may be differences in color between different batches of products.

reason: Pigments are unevenly dispersed, Material batches are different, Changes in injection molding process parameters, etc.

Poor bonding between cladding layer and base material

Choose the right material combination, Make sure both have good compatibility.

Optimize injection molding process parameters, such as increasing the temperature, increase pressure, Extend the holding time, etc., Enhance bonding force.

Improve mold design, Increase the roughness of the joint, Set up special structures etc., Improve bond strength.

Surface defects

Adjust injection speed and pressure, Avoid going too fast or too slow, Ensure plastic flows smoothly.

Optimize mold temperature control, Evenly distribute temperature, Avoid local overheating or cooling.

Improve mold surface quality, polishing, Reduce surface roughness.

Add exhaust system, Evacuate the gas in the mold promptly, Prevent bubbles from forming.

Dimensional deviation

Designing parts is not within our scope as a contract manufacturer, But we can provide some guidance on Design for Manufacturability (DFM). via DFM, We can advise on how to optimize your design, Reduce costs while retaining functionality.

Color difference

Ensure pigments are evenly dispersed, Methods such as premixing or increasing mixing time can be used.

Strictly control material batches, Try to use materials from the same batch.

Stable injection molding process parameters, avoid temperature, Changes such as pressure affect color.

Material compatibility

1. The problem of combining different materials: Choosing the right combination of base and cladding materials is critical. If the chemical properties of two materials, Shrinkage, There is a big difference in liquidity, etc., May cause poor binding, Issues such as delamination or cracking.

2. Differences in thermal expansion coefficients of materials: when the temperature changes, Different materials have different coefficients of thermal expansion, May cause stress concentration, Affects the dimensional stability and bonding strength of the product.

Process complexity

1. Precise process parameter control: Overmolding requires precise control of injection temperature, pressure, Speed and other parameters, to ensure uniform coating, Covers the base material flawlessly. Small changes in parameters can have a significant impact on product quality.

2. Sequence and time control of multi-material injection molding: For overmolding involving multiple materials, The injection molding sequence and time need to be reasonably arranged, To avoid interference and adverse effects between different materials.

三、Mold design requirements are high

1. Complex mold structure: In order to achieve good coating effect, Molds often require the design of complex runner systems, Parting surface and demoulding mechanism. This increases the difficulty and cost of mold manufacturing.

2. Mold cooling and heating system design: Due to the different cooling and solidification characteristics of different materials, Need to design efficient cooling and heating systems, To ensure product quality and production efficiency.

Quality control is difficult

1. High appearance quality requirements: Overmolded products usually have higher requirements on appearance quality, such as surface smoothness, color uniformity, No defects etc.,This requires strict quality control and testing methods.

2. Difficulty in internal quality inspection: Regarding the bonding strength between the cladding layer and the base material, Internal defects and other issues, Detection is difficult, Advanced non-destructive testing technology is required.

Cost and efficiency balance

1. High mold cost: Complex mold structures and high-precision manufacturing requirements lead to higher mold costs. This may not be economical for small batch production or rapid product replacement.

2. Production efficiency improvement challenges: The process complexity of overmolding may affect production efficiency. How to improve production efficiency while ensuring product quality, is a problem that needs to be solved.

Our CNC machining services have been praised by global customers from different fields。We supply CNC machining components to a variety of industries,Covers the following and more

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

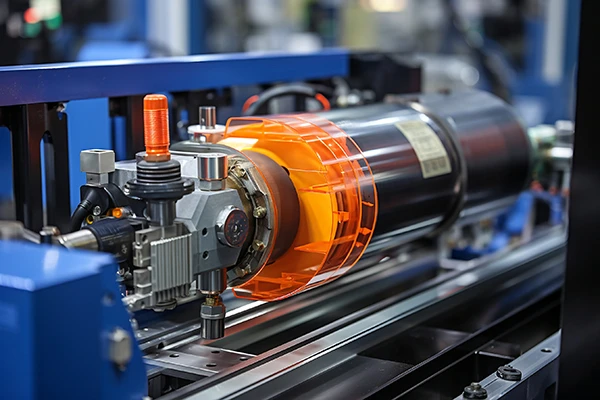

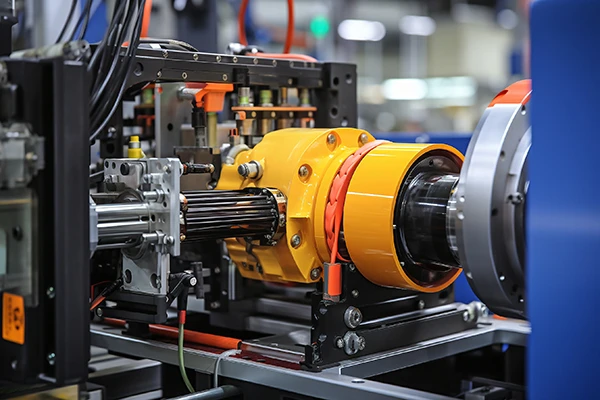

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

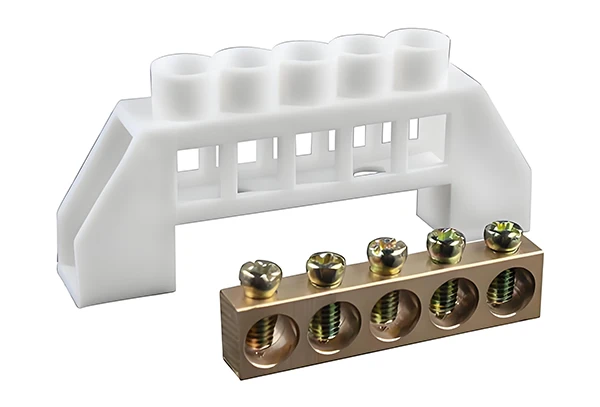

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.