Stereolithography

Serve

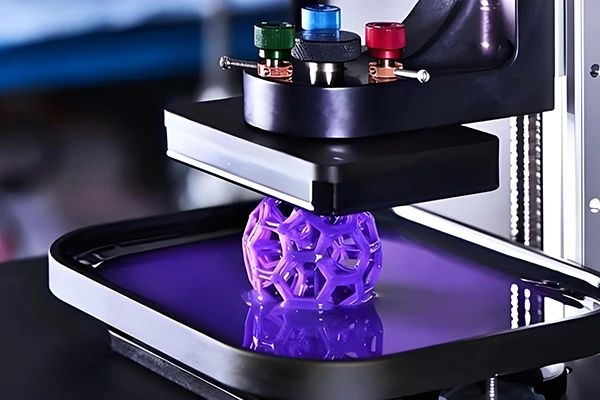

The core of SLA technology lies in photopolymerization reaction. Liquid photosensitive resin will polymerize under specific wavelengths of ultraviolet or laser irradiation, Quickly solidifies.

Start a new injection molding quote

Our stereolithography part capabilities

Choose Rapidefficient Stereolithography, Because of its high precision, high speed, high surface quality, Able to meet complex design requirements with controllable costs.

Stereolithography (SLA) is a 3D printing technology based on the principle of photopolymerization, Also known as light-curing molding technology or liquid bath photopolymerization method. SLA cures liquid photosensitive resin layer by layer using ultraviolet light or lasers, Form the desired three-dimensional structure.

Main materials: The materials used in SLA technology mainly include light-cured acrylic resin and epoxy resin, These materials have different mechanical properties and application characteristics.

optional materials: In addition to standard resin, There are also rubber materials, Wax substitutes and more, Suitable for different application needs.

Complex part prototyping

Able to quickly produce prototypes of complex-shaped parts, High precision, Help product design verification. such as early models of auto parts.

Small batch customized production

Suitable for small batch personalized product production, low cost, short cycle. Such as customized electronic product casings.

Medical model production

High-precision production of human organ models, etc., Assisted medical diagnosis and surgical planning. Such as cardiac models for preoperative analysis.

Jewelry Design and Manufacturing

Precise presentation of complex jewelry designs, high surface quality. Such as unique shape necklace pendant.

Educational teaching model

Provide intuitive three-dimensional models for teaching, Enhance learning effect. For example, molecular structure models are used in chemistry teaching.

Industrial design verification

Quickly verify industrial design solutions, Easy to modify. Such as design verification of new lamp housings.

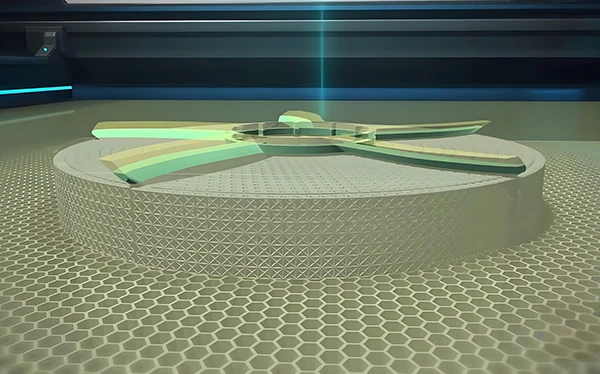

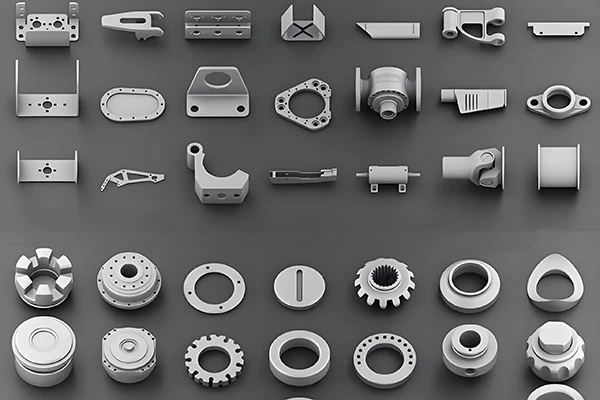

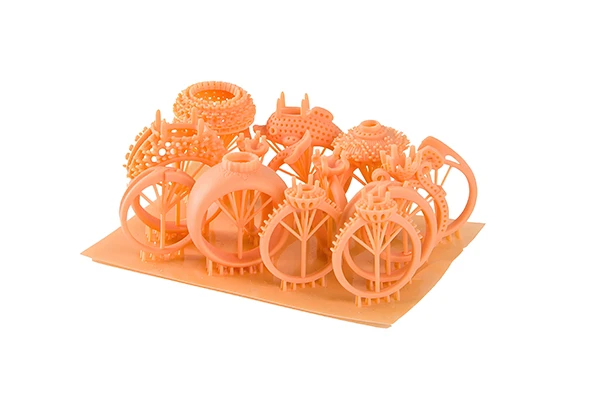

Stereolithography Parts Display, Every piece is carefully crafted, Represent complex designs with high precision, smooth surface, Showing the perfect integration of technology and art.

Ability to accurately render complex designs, Achieve micron-level precision, For fine structures such as tiny parts, Jewelry and other items can be accurately shaped.

The printed parts have high surface smoothness, Achieve better appearance without excessive post-processing, Suitable for applications with high appearance requirements.

Various types of photosensitive resin materials can be used, include transparency, Flexible, Casting and other special resins, Meet different functional needs.

Design preparation

1. Design parts using professional 3D modeling software, Ensure model accuracy and completeness. Consider the function of the part, size, Structural and other factors, Carry out reasonable design optimization.

2. Check the model for errors or unreasonable structures, such as self-intersection, Suspended parts, etc., Repair in time.

Choose equipment and materials

1. Select the appropriate stereolithography equipment according to the requirements of the part, Consider the accuracy of your equipment, Print size, Speed and other parameters.

2. Choose the right photosensitive resin material, Different materials have different performance characteristics, such as hardness, toughness, Transparency etc.

Slicing and parameter settings

1. Import 3D models into slicing software, Perform slicing, Set appropriate layer thickness, Exposure time and other parameters.

2. Optimize parameters to balance print quality and time, Thinner layer thickness usually improves accuracy but increases print time.

Printing process

1. Pour photosensitive resin into printer trough, Start the device to start printing.

2. Observe the printing process, Ensure equipment is functioning properly, Deal with possible problems promptly, Such as resin leakage, Uneven curing, etc.

Post-processing

1. After printing is completed, Remove the part from the build platform, Remove support structures (if any).

2. perform cleaning, Remove uncured resin. Solvents such as alcohol can be used for cleaning.

3. Post-cure as needed, Improve part strength and stability.

Quality inspection

1. Check the dimensional accuracy of parts, surface quality, Structural integrity, etc.

2. Use measuring tools, Tools such as microscopes for measurement and observation, Ensure parts meet design requirements.

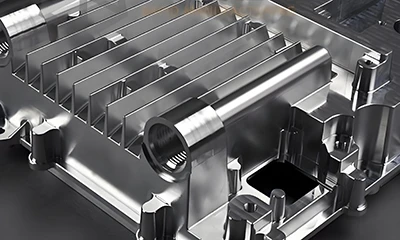

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential

Accuracy deviation

Reason: Equipment accuracy is insufficient, material shrinkage, Improper slicing parameter settings, etc.

Performance: Part size does not match design size, Rough surface, etc.

Solution

Choose high-precision equipment, and perform regular calibration and maintenance.

Understand the shrinkage characteristics of materials, Compensate at design time.

Optimize slicing parameters, If the layer thickness is reduced, Adjust exposure time, etc.

Deformation

Reason: Material shrinks unevenly, Temperature changes during printing, Unreasonable support structure design, etc.

Performance: Parts bend, distortion, Warping, etc.

Solution

Optimize support structure design, allowing it to support the part evenly, Reduce deformation.

Control printing environment temperature, Avoid excessive temperature changes.

Choose materials with low shrinkage.

Delamination and cracking

reason: Poor bonding between layers, Poor material performance, Unreasonable printing parameters, etc.

Performance: Delamination appears on the surface of the part, Will crack in severe cases.

Solution

Adjust printing parameters, If you increase the exposure time, Improve bonding strength between layers.

Choose good quality, Materials with stable performance.

Post-process parts, Such as heating and curing, etc., Improve bonding between layers.

Support structures are difficult to remove

Reason: The support structure design is unreasonable, The material is highly sticky, etc.

Performance: When removing support structures, Easily damaged parts or residual support material.

Solution

Proper design of support structures, make it easy to remove.

Choose the right support material, Reduce material viscosity.

When removing support structures, Use appropriate tools and methods, Handle with caution.

Printing failed

Reason: Equipment failure, Material problem, Parameter setting errors, etc.

Performance: Printing process interrupted, Part cannot be completely formed.

Solution

Check if the device is functioning properly, Troubleshoot promptly.

Ensure material quality is up to standard, Avoid using expired or contaminated materials.

Double check parameter settings, Make sure it’s correct. If printing fails, Analyze the cause and adjust the parameters before printing again.

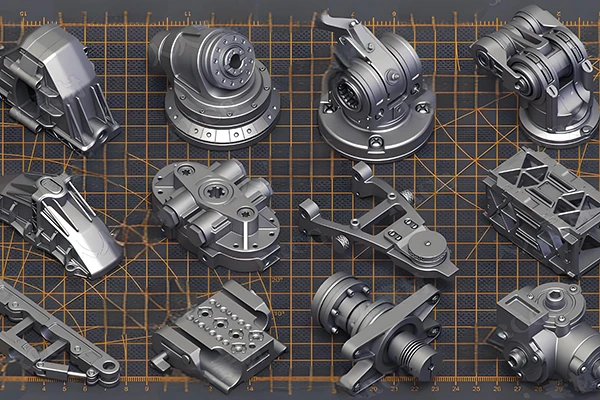

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

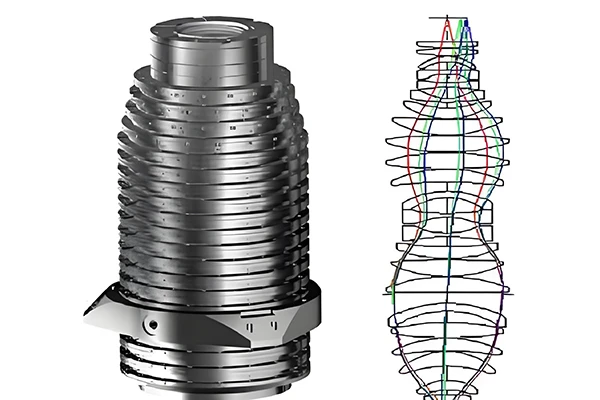

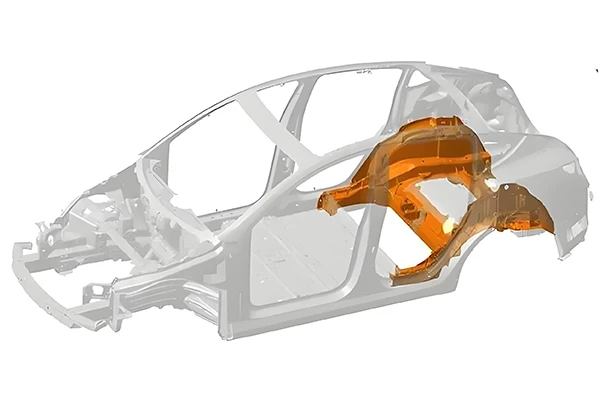

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.