Direct metal laser sintering

Serve

One-off CNC machining prototype

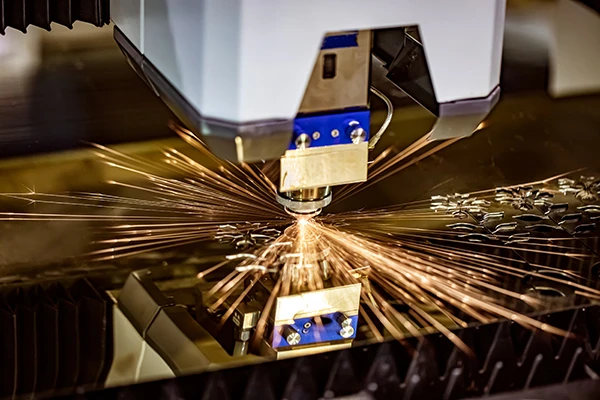

Our direct metal laser sintering capabilities

Choose Rapidefficient Direct Metal Laser Sintering, Because it has high precision, Able to create complex shapes, Suitable for a variety of metals and efficient.

Direct metal laser sintering (DMLS) is a 3D printing technology based on the selective sintering of metal powders by laser beams.The basic principle is to use a high-energy laser beam to sinter metal powder layer by layer, Form the desired three-dimensional structure.

Commonly used metal powder materials:

Stainless steel: Has good mechanical properties and corrosion resistance, Suitable for manufacturing structural parts and tools.

cobalt chromium alloy: High strength and high temperature resistance, Widely used in aerospace and medical fields.

Aerospace parts manufacturing

Able to accurately manufacture complex shapes, Aerospace components with thin-walled structures and extremely high performance requirements, like engine blades, Turbine disc, etc., Meeting the needs of the aerospace industry for lightweighting and high performance.

Medical device production

High-precision medical devices can be customized and produced according to the patient’s unique physiological structure, such as orthopedic implants, Dental restorations, etc., Good compatibility with human tissue.

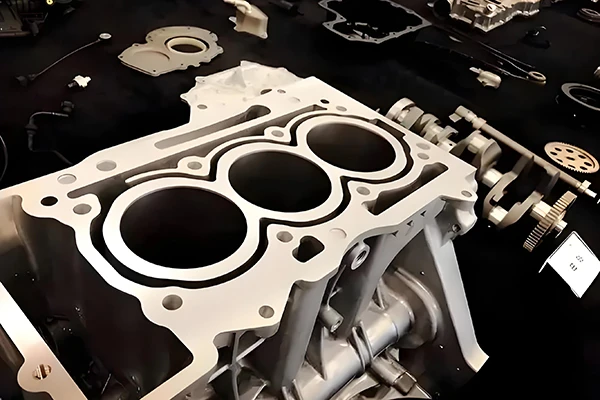

Auto parts processing

Rapidly manufacture complex shapes, Finely structured automotive parts, such as engine block, Transmission gears, etc., Helps improve vehicle performance and lightweight.

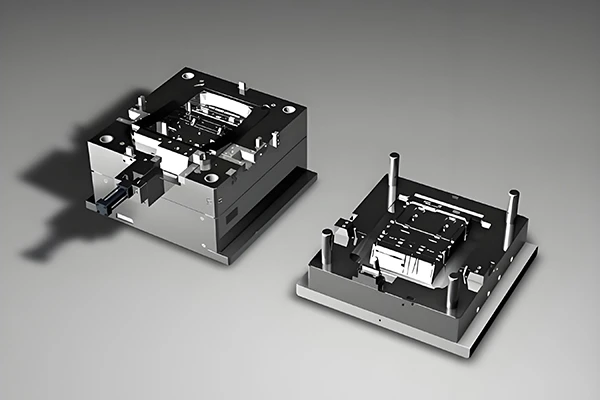

Mold making

Ability to efficiently manufacture molds with complex internal structures and high surface quality, Such as injection mold, Die casting mold, etc., Shorten mold development cycle and manufacturing costs.

Art design and creative products

Provides artists and designers with great creative freedom, Various unique, Complex artistic designs and creative products, like sculpture, Jewelry etc., Perfectly transform ideas into real objects.

Research and Education Model

Used for rapid manufacturing of complex experimental models in scientific research fields, and the production of teaching models in the field of education, Help researchers and students better understand and study relevant scientific principles and structures.

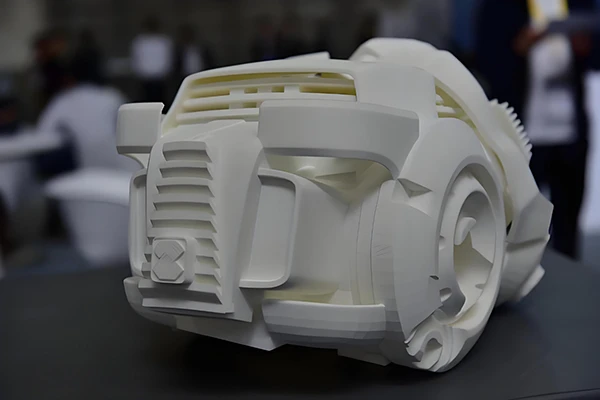

Direct metal laser sintering parts display, Every piece is carefully crafted, Represent complex designs with high precision, Showcase the unique charm of advanced manufacturing.

Extremely complex shapes can be manufactured accurately, with internal cutouts, thin wall, Parts with special curved surfaces and other structures, Can meet a variety of unique design needs, Almost no shape restrictions.

This technology is layered processing, Just use the corresponding metal powder material according to the shape of the part, Unsintered powder can be recycled and reused, Reduced material waste, Reduced production costs.

Laser sintering tightly combines metal powder particles, Formed parts have good density and mechanical properties, such as high intensity, High hardness, Good wear resistance, etc., Can be directly used in situations that require higher performance of parts.

Design preparation

1. Design parts using professional 3D modeling software, Ensure model accuracy and completeness, Consider part functional requirements and manufacturability.

2. Check the model for errors or unreasonable structures, such as self-intersection, Parts that are too thin, etc., and fix it.

Material selection

1. Select the appropriate metal powder material according to the performance requirements and application scenarios of the part, such as stainless steel, Titanium alloy, Aluminum alloy, etc.

2. Understand the properties of different materials, such as intensity, hardness, Corrosion resistance, etc., To ensure that the selected material can meet the usage requirements of the part.

Equipment preparation

1. Choosing the right direct metal laser sintering equipment, Consider the accuracy of your equipment, Print size, Laser power and other parameters.

2. Inspect and debug equipment, Make sure equipment is in good working order, Includes laser system, powder conveying system, Control system, etc.

Slicing and parameter settings

1. Import 3D models into slicing software, Perform slicing, Set appropriate layer thickness, Laser power, Scanning speed and other parameters.

2. Parameter optimization based on material characteristics and part requirements, for optimal print quality and performance.

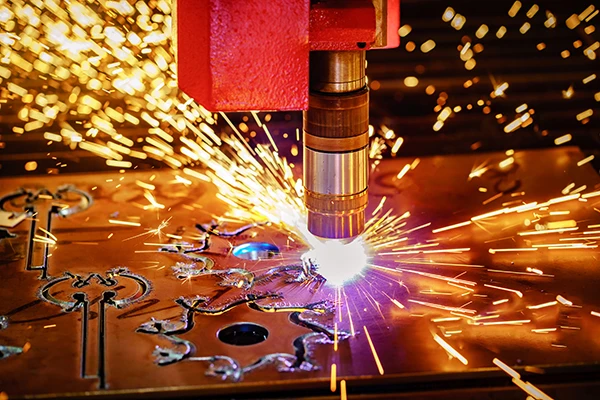

Printing process

1. Loading metal powder into the powder bed of the equipment, Start the device to start printing.

2. Observe the printing process, Ensure equipment is functioning properly, such as laser scanning tracks, Powder spreading conditions, etc., Deal with possible problems promptly.

3. After printing is completed, Wait for parts to cool to room temperature, Avoid deformation or cracking of parts due to temperature changes.

Post-processing

1. Remove the printed part from the powder bed, Remove excess powder, Can be cleaned using compressed air or a vacuum cleaner.

2. Post-process parts, Such as heat treatment, Surface treatment, etc., to improve part performance and surface quality.

3. Conduct quality inspection, Use measuring tools, Microscope and other tools to check the dimensional accuracy of parts, surface quality, Internal structure, etc., Ensure parts meet design requirements.

Things to note

1. Operators need professional training, Be familiar with equipment operation and safety practices.

2. During printing, Pay attention to safety, Avoid laser damage to human body, At the same time, it is necessary to prevent dangerous situations such as powder leakage and explosion.

3. Perform regular maintenance and upkeep on equipment, Ensure equipment performance and accuracy, Extend the life of your equipment.

Whether you need a small number of parts or 10000 Multiple production objects that are ultimately put into use, CNC machining is an ideal manufacturing method. The following are the customized CNC services we launch.

By Rapidefficient, You can complete product manufacturing in a short time, so as to be able to quickly enter the market.

Efficient mold making is a cost-effective way, Able to bridge the gap between sample production and mass production. Quickly let your products occupy the market.

For custom projects, Our professional team will help you achieve the best products in terms of quality and efficiency.

All information and uploaded materials are secure and confidential.

Insufficient density

Reason: Insufficient laser energy, Scan speed too fast, The metal powder particle size distribution is unreasonable or the powder layer thickness is inappropriate, etc., may cause the metal powder to fail to completely melt and fuse, As a result, the density of the parts is insufficient.

Solution: Increase the laser power appropriately, Reduce scanning speed, Ensure that the laser energy can fully melt the metal powder; Optimize powder size distribution, Choosing the right powder material and particle size range; Adjust powder layer thickness, Generally speaking, Thinner powder layers help increase density, But being too thin may affect printing efficiency, Need to find a suitable balance point.

Dimensional accuracy deviation

Reason: Non-uniformity in laser spot size and shape, Mechanical accuracy error of equipment, Factors such as thermal expansion caused by temperature changes, This may cause the printed part size to deviate from the design size.

Solution: Calibrate and maintain equipment regularly, Ensure the accuracy of laser systems and mechanical motion systems; When designing parts, Taking into account the thermal expansion coefficient of the material, Leave a certain size margin; Optimize parameter settings of slicing software, Improve slicing precision and accuracy.

Higher surface roughness

Reason: Particle size of metal powder, Factors such as shape and laser scanning strategy can affect the surface roughness of the part. For example, Larger particle size powders or inappropriate scanning strategies may result in uneven surface appearance on the part.

Solution: Smaller selection granularity, Regularly shaped metal powder; Adopt an appropriate scanning strategy, Such as increasing the number of laser scans, Adjust scanning spacing, etc., To improve the surface quality of parts; After printing is complete, Perform appropriate post-processing, such as sandblasting, Grinding etc., further reduce surface roughness.

Deformation and warping issues

Reason: During printing, Uneven shrinkage of metal powder, The existence of temperature gradient and unreasonable design of part structure, etc., may cause deformation and warping of parts.

Solution: Optimize the structural design of parts, Try to avoid large flat surfaces, Cantilever structures and other parts that are prone to deformation; During printing, Use appropriate warm-up and cool-down strategies, Reduce temperature gradient, Reduce the internal stress of parts; For parts that are easily deformed, Support structures can be added, to increase the rigidity of the part, Prevent deformation, But the support needs to be removed after printing is completed, May have a certain impact on the surface quality of the parts.

Spheroidization phenomenon

Reason: High viscosity in liquid phase, High surface tension, The melt material does not wet the solid particles and substrate under the influence of factors such as, Metal powder may spheroidize during the laser sintering process, That is, the powder particles fail to fully spread and fuse, Instead, a spherical structure is formed. This affects the molding quality and surface flatness of the part.

Solution: Choosing the right metal powder material and particle size, Reduce the surface tension and liquid viscosity of powders; Adjust laser parameters, If appropriate, increase the scanning speed or reduce the laser power, Can reduce the spheroidization effect to a certain extent; Optimize powder spreading methods and process parameters, Ensure that the powder can be spread evenly on the substrate.

Laser system failure

Reason: Aging of laser generator, Damage or contamination of optical components, etc., may cause the laser power to decrease, Problems such as laser spot shape and uneven energy distribution, Affect print quality.

Solution: Perform regular maintenance and upkeep on the laser generator, Replace aging parts; Keep optics clean, avoid dust, The impact of oil and other contaminants on optical components; during use, Pay attention to monitoring the working status of the laser system, Find and handle faults promptly.

Powder conveying system failure

Reason: Powder feeder in powder conveying system, Components such as powder spreading rollers may become clogged, Problems such as wear or jamming, Resulting in poor powder transportation, Affecting the normal progress of the printing process.

Solution: Clean the powder feeder and spreading roller regularly, Prevent powder clogging; Inspecting the mechanical components of the powder conveying system, Promptly replace worn or damaged parts; Optimize storage and delivery conditions for powders, Keep the powder away from moisture, Problems such as caking.

Material compatibility issues

Reason: Different metal powder materials have different physical and chemical properties, In the direct metal laser sintering process, Incompatibilities between materials may occur, Causing print failure or poor part performance.

Solution: When choosing materials, Full consideration should be given to material compatibility, Carry out relevant tests and verifications; For parts that require the use of multiple materials, Can be printed in layers or mixed materials, However, we need to pay attention to the interface bonding issues between different materials.

Oxidation and contamination of powder materials

Reason: Metal powder during storage and use, Vulnerable to oxidation and contamination, This can affect material performance and print quality.

Solution: When storing metal powder, keep dry, sealed environment, Avoid moisture and oxidation of powder; before use, Screening and purification of powders, Remove impurities and oxides; During printing, Protective gas can be used, such as argon, Nitrogen, etc., To prevent oxidation of metal powder.

Our CNC machining services have been praised by global customers from different fields, We supply CNC machining components to a variety of industries, Covers the following and more.

Large size parts, Such as CNC machined ABS bumpers, PC/ABS instrument panels and precision automotive parts, Reflector for example, lens, Steering wheel assembly, engine, transmission.

Robot parts for the robotics and automation industry, actuator, end effector, Motor, Automatic control equipment, Fixtures and housings.

Stainless steel or titanium bone plate, prosthesis, respiratory equipment, handheld device, diagnostic equipment, anatomical model, Components for medical needs such as surgical instruments.

Aero engine, body, turbine, brake, tire parts, lighting system, Vacuum pump and fuel pump parts.

Consumer products, such as electronic equipment casings, button, handle, Knob, switch, wearable digital devices, Cookware products, sports equipment.

New energy industry components, e.g. heat exchanger, valve, pipeline, Pumps and accessories, Hydraulic components, Battery components, solar panel components, Frame and impeller.

Electronic housing, conveyor belt, fastener, connector, Generator components, fixtures, Machine and tool parts for industrial machinery.

Actual models can be created based on semiconductor requirements, Engineering models and other experimental equipment, We work with universities around the world.