Semiconductor component prototyping

RapidEfficient provides high-quality manufacturing assurance for your exclusive semiconductor component solutions and semiconductor equipment. Customized on demand at affordable prices, Get started faster, Reduce hidden dangers and optimize production links.

Extremely fast innovation

Excellent and efficient

Unique charm

Provide agile and high-quality rapid prototyping solutions, Covers industry, medical, transportation, Energy and environmental protection and other professional fields. From initial idea to finished part, We have state-of-the-art facilities and deep expertise to achieve the most challenging designs.

RapidEfficient’s professional team has the capabilities and experience to fulfill your semiconductor component orders, Regardless of technical complexity or material properties. Get your design budget or contact us, Learn how we can work alongside you in your semiconductor industry.

Can we still make it?

We can also make these

CNC machining

By using CNC numerical control processing technology, We can create prototypes and production parts in a variety of complex shapes.

Die casting

We provide small batch test molds and high-volume production molds.

3D print

We provide 4D printing services for specialty material parts using a range of advanced additive manufacturing technologies.

Promising semiconductor component manufacturing

From chip transfer systems to data processing equipment to performance enhancement devices, Many semiconductor transmission systems are composed of multiple components, These parts often have elaborate and intricate designs. Manufacturing these parts, whether for small pilot prototypes or high-volume production, requires finding producers with the capabilities and expertise to take on the project. Whether components of new semiconductor monitoring equipment manufactured through advanced technology, Or a semiconductor storage box made of high-strength materials, RapidEfficient can meet your orders.

Semiconductor simulation equipment plays a variety of key roles in semiconductor technology learning. in the field of education, They are used to train the next generation of semiconductor engineers, Technicians and other related professionals. at the same time, In a semiconductor R&D environment, They can be used for pre-test preparation for specific semiconductor projects, For example, providing a clear representation of the functionality of the semiconductor to be tested. Modern manufacturing techniques make it more efficient to manufacture such equipment from precise designs.

Semiconductor testing equipment, Monitoring instruments and analytical equipment are just a few of the new composite materials we can use, Semiconductor-applicable materials such as special materials and precision processing, Injection molding, Some of the most important everyday semiconductor components made using advanced manufacturing processes such as die casting and 3D printing. Whether you need an initial prototype or a large quantity of parts, We can all manufacture complex designs or standard parts to your exact specifications.

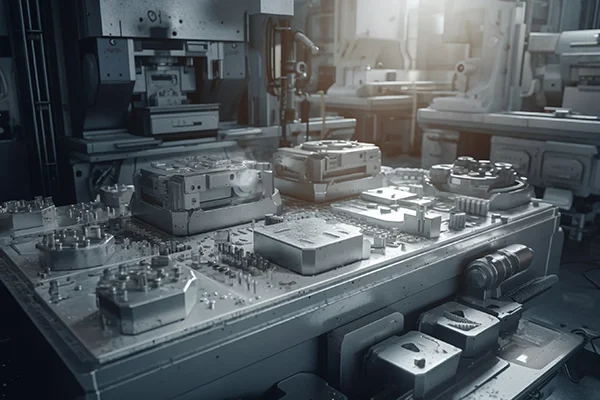

Partial display of semiconductor parts

over the years, We continue to accumulate relevant experience, Give us the ability to undertake any semiconductor component model production task. Below is a collection of images of semiconductor component model samples and production assemblies we create for our global customers.

A wide range of materials are available for all our manufacturing processes. Listed below are some common options for semiconductor component projects.

Available in a variety of high level surface treatments. We list just some of the common surface treatment options. More surface treatment options for custom parts for the semiconductor component industry.

FAQ

Is Rapidefficient Manufacturing ISO certified?

Yes, Rapidefficient Manufacturing is an ISO9001-2015 certified manufacturer. No matter what kind of project or every customer, We all manufacture parts to high standards.

Can samples be provided?

For some manufacturing processes (such as die-casting), We can provide initial samples of your parts, Then provide subsequent samples according to demand.

How long will it take to get my parts?

We can fulfill orders quickly, But the delivery time depends on some factors, such as manufacturing processes, Order quantity and part complexity. The fastest way to CNC machine parts is 4 sky, 3The fastest way to 3D print parts is just 2 sky, The mold manufactured through rapid tooling is the fastest and only needs 4-6 sky.

I want to protect my intellectual property – are my designs safe?

Rapidefficient manufacturing takes privacy and security seriously, and will happily sign a non-disclosure agreement (NDA) upon your request, Let you feel confident about your intellectual property rights.