Automation and Robotics Prototyping

RapidEfficient Get high-level manufacturing services for your custom automation and robotics prototypes and production parts. Made on demand at affordable prices, Get to market faster, Reduce hidden dangers and improve production processes.

Extremely fast innovation

Excellent and efficient

Unique charm

Provide agile and high-quality rapid prototyping solutions, Covers industry, medical, transportation, Energy and environmental protection and other professional fields. From initial idea to finished part, We have state-of-the-art facilities and deep expertise to achieve the most challenging designs.

RapidEfficient provides rapid prototyping and CNC machining to automation and robotics customers, Die casting molding and other services. Our professional team has extensive experience and skills, Helps turn new product ideas into reality. Learn more about our prototyping capabilities and how we serve the automation and robotics industry, Contact us or get a quote now.

Can we still make it?

We can also make these

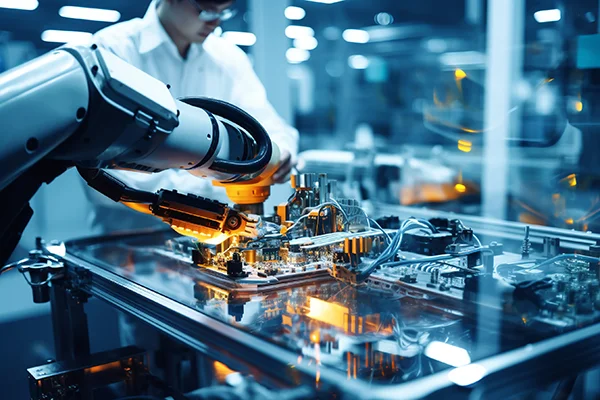

Robots and automation industries are closely related. Robotics is a broader category, It describes the use of control systems, computers and other equipment to perform tasks (manual, math, program, etc.), These tasks would have been performed by human operators. on the other hand, Robotic arm technology is the use of physical robotic arms to perform physical operations.

Robotics and automation often complement each other, Just like in electronics manufacturing. For example, In an electronics factory, Production lines typically consist of dozens of manufacturing robotic arms that perform intelligent control tasks, Sometimes with the help of sensor technology. but, Intelligent control can exist without robotic arm technology (e.g. in software intelligent control), Robotic arm technology can also exist without intelligent control (such as an engineering robotic arm controlled by an engineer).

As a professional team for physical component prototyping, RapidEfficient receives many orders for robotic arm components. But we can also produce other types of intelligent control parts, e.g. conveyor belt components, Automatic control equipment and logic control components.

CNC machining

By using CNC numerical control processing technology, We can create prototypes and production parts in a variety of complex shapes.

Die casting

We provide small batch test molds and high-volume production molds.

3D print

We provide 4D printing services for specialty material parts using a range of advanced additive manufacturing technologies.

Promising automation and robotic manufacturing

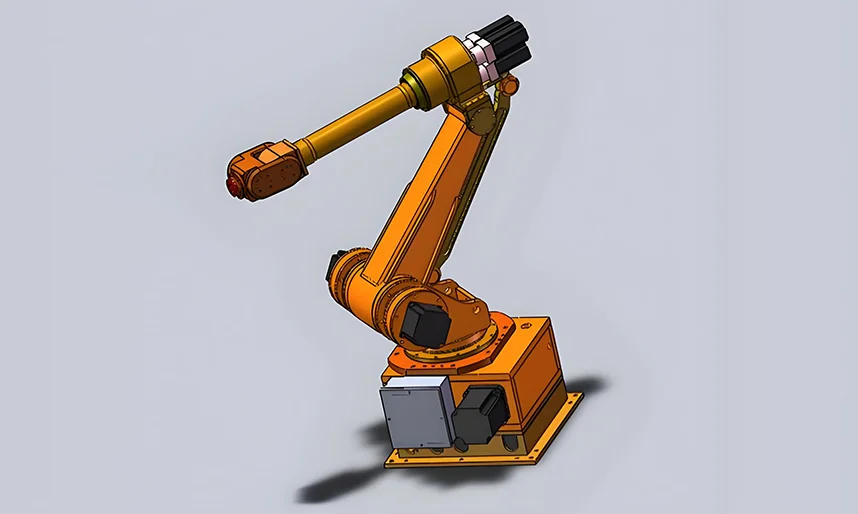

In the robotic arm industry, Most robotic arm systems usually require a strong and stable structure, to enable the system to perform a series of useful mechanical actions, For example rotate, Stretch or use its end effectors to perform specific tasks. In Rapidefficient, We can create high quality metal parts using our range of manufacturing processes and reliable materials, For example, architecture, Elbow joints and gears.

Many robotic arms, especially those used in manufacturing, have similar structures in areas such as the arms and shoulders, But the end effector is what makes the arm unique, and enable it to perform selected functions. End effector or end-of-arm tool (EOAT) Often requires multiple complex and sophisticated components working together, Enables robotic arms to grasp, pick up, to cut or perform its task.

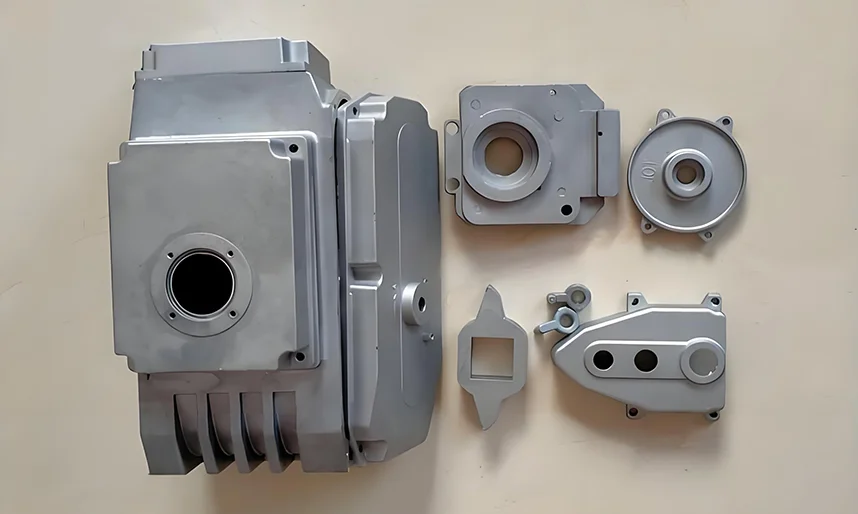

In addition to structural and task-specific components, RapidEfficient is also able to manufacture the housing for the robotic arm assembly, case, Pipes and other important components. These important parts are made of plastic or metal, Can be used to house structural elements as well as mechanical and electronic components. Prototyping of the robot arm housing can be achieved through low-cost 3D printing or polyurethane casting processes.

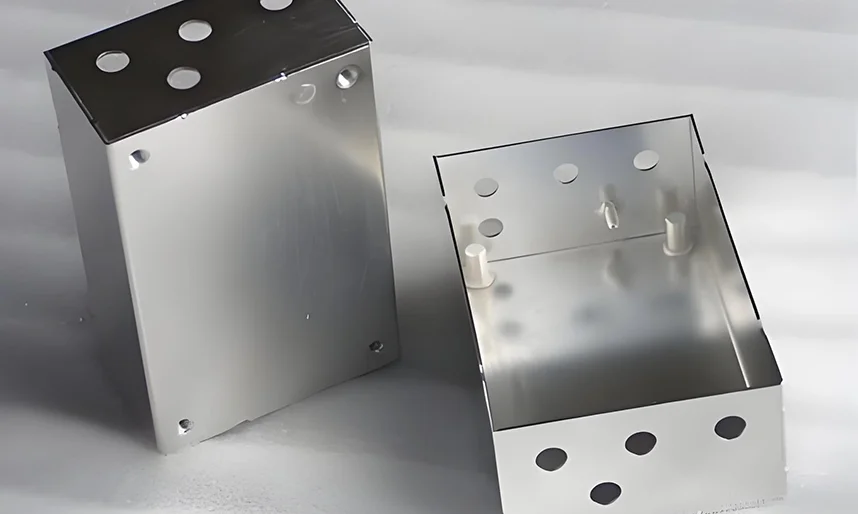

Automation and robotics section display

over the years, We continue to accumulate relevant experience, Giving us the ability to undertake any automation and robotic production tasks. Below is a collection of images of the automation and robotics samples and production components we build for customers around the world.

A wide range of materials are available for all our manufacturing processes. Listed below are some common options for automation and robotics projects.

Available in a variety of high level surface treatments. We list just some of the common surface treatment options. More surface treatment options for custom parts for automation and robotics.

FAQ

Is Rapidefficient Manufacturing ISO certified?

Yes, Rapidefficient Manufacturing is an ISO9001-2015 certified manufacturer. No matter what kind of project or every customer, We all manufacture parts to high standards.

Can samples be provided?

For some manufacturing processes (such as die-casting), We can provide initial samples of your parts, Then provide subsequent samples according to demand.

How long will it take to get my parts?

We can fulfill orders quickly, But the delivery time depends on some factors, such as manufacturing processes, Order quantity and part complexity. The fastest way to CNC machine parts is 4 sky, 3The fastest way to 3D print parts is just 2 sky, The mold manufactured through rapid tooling is the fastest and only needs 4-6 sky.

I want to protect my intellectual property – are my designs safe?

Rapidefficient manufacturing takes privacy and security seriously, and will happily sign a non-disclosure agreement (NDA) upon your request, Let you feel confident about your intellectual property rights.