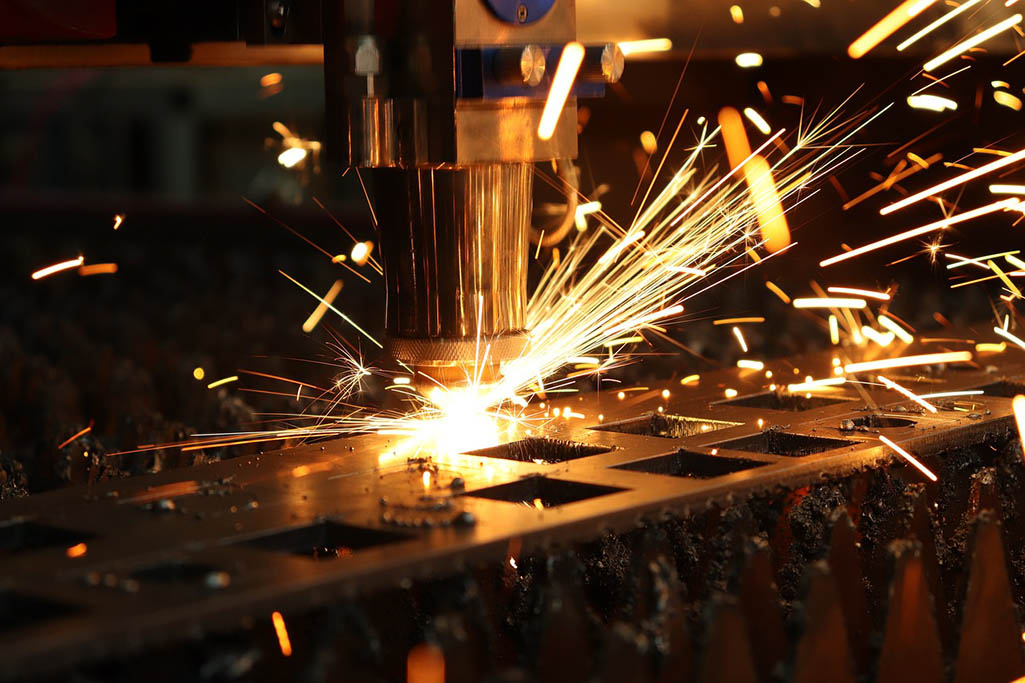

CNC machining,As the intelligent cornerstone of modern manufacturing,Its basic principle contains an exquisite combination of technology and craftsmanship。CNC,computer numerical control,through preprogrammed computer instructions,Precisely control various movements of machine tools,Achieve high efficiency of parts、High precision machining。

existCNC machiningmiddle,Computer is the core brain。Engineers utilize professional CAD/CAM software,Convert design drawings into CNC programs readable by machine tools。These programs specify the path of the tool、Key information such as cutting parameters,Ensure accuracy during processing。

When the CNC program is loaded into the CNC machine tool,The machine tool’s control system begins to interpret and execute these instructions.。Through precision transmission devices such as servo motors,Machine tools can precisely control tool displacement and speed,Realize complex machining tasks。Whether it is simple straight line cutting,Or complex surface modeling?,CNC machining can be completed with extremely high precision and efficiency。

Basic principles of CNC machining,Reflects the huge advantages of digital technology in manufacturing。It makes the processing process more controllable、Predictable,Greatly improve production efficiency and parts quality。at the same time,CNC machining also offers a high degree of flexibility,Able to adapt to different shapes、Processing requirements for parts made of different materials。

In short,CNC machining is an integral part of modern manufacturing,Its basic principles and applications demonstrate digital、The huge potential of intelligent technology in manufacturing。With the continuous advancement and innovation of technology,,CNC machining will surely play a more important role in the future,Promote the development of manufacturing industry to a higher level。

Rapid Efficient is a leading provider of rapid prototyping and parts processing and manufacturing services,Focus on prototype production of plastic and metal parts、Custom processing and small batch production,Provide one-stop service from prototype to mass production。

With advanced manufacturing technology and highly skilled team,We always maintain an excellent competitive advantage。Our manufacturing services meet your specific product design needs,Including CNC machining、3D printing、Silicone mold vacuum injection molding、Rapid molding and small batch injection molding, etc.。

Our business model is based on providing cost-effective solutions,Enable customers to benefit at all stages of their new product development。Our most proud social value is the recognition of customers from all over the world through word-of-mouth growth.,These range from independent inventors or designers to large industrial、Business、medical、car、Medical and other fields