Sheet metal processing plays a crucial role in many industries, including automotive, aerospace, construction, and electronics. This process involves transforming raw metal into various products through a series of steps. Understanding the essential stages of sheet metal processing allows businesses to make better decisions for their manufacturing needs. Below, we explore the main steps involved in the process, highlighting the tools and techniques used in each phase.

Step 1: Design and Planning

The first step in sheet metal processing involves creating a design. Engineers actively use Computer-Aided Design (CAD) software to develop detailed blueprints of the part. They ensure these designs contain precise measurements and specifications to meet quality standards.

After designing, manufacturers move on to the planning phase. They determine which tools and methods to use to fabricate the metal effectively. This careful planning helps them optimize the process and minimize waste. As a result, manufacturers can reduce both production time and costs, making the process more efficient from the start.

Step 2: Cutting the Metal

Once the design and plan are set, the next step is cutting the metal to the desired shape and size. Various cutting methods are used depending on the material and complexity of the design. Some of the most common cutting techniques include:

- Laser Cutting: A laser beam cuts through metal with extreme precision. It works best for intricate designs.

- Plasma Cutting: This method uses ionized gas to cut thicker metals. While fast, it’s not as precise as laser cutting.

- Shearing: This technique involves a large blade cutting straight lines through thin metal sheets.

These cutting techniques ensure the metal pieces match the exact dimensions in the design. Getting this step right is essential to ensure a smooth and accurate fabrication process.

Step 3: Bending and Forming

After cutting, fabricators bend and form the metal into the desired shape. They typically use press brakes, which apply pressure to the metal to create bends at precise angles. This step is key for forming structural and functional parts.

For more complex shapes, fabricators may use techniques like roll forming or stamping. Roll forming gradually shapes the metal by passing it through a series of rollers. Stamping, on the other hand, uses a die and punch to form the metal into a shape quickly. These techniques make it possible to create more intricate designs efficiently.

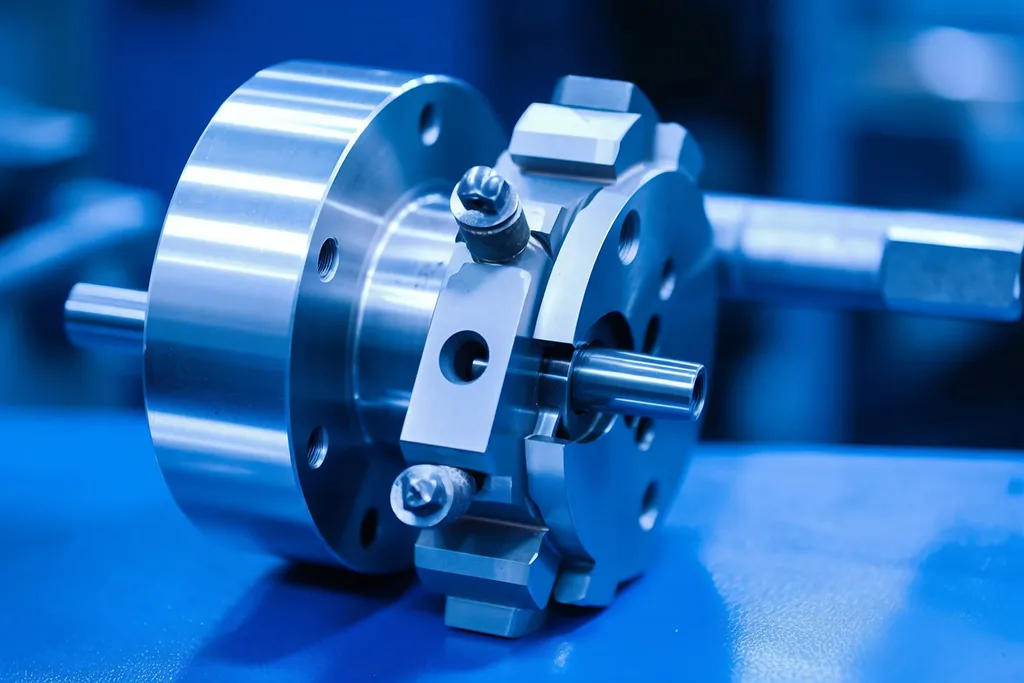

Step 4: Assembling the Parts

Once the metal has been cut and shaped, it’s time to assemble the pieces. Manufacturers use several methods to join metal parts, depending on the project’s needs. The most common techniques include:

- Welding: By applying heat, fabricators fuse metal parts together to form strong bonds.

- Riveting: This method involves fastening metal parts with metal rivets, which is useful in industries like aerospace.

- Fastening: Bolts, screws, and nuts provide another option, allowing for easy disassembly if needed.

Fabricators focus on ensuring that the parts are correctly aligned and securely joined. This step is critical in determining the final product’s strength and durability.

Step 5: Finishing

After assembly, fabricators finish the product to improve its appearance and enhance its performance. Common finishing processes include:

- Polishing: This step smooths the metal surface, giving it a shiny, decorative look.

- Powder Coating: Fabricators apply a dry powder to the metal surface, then heat it to form a protective layer. This provides excellent resistance to corrosion and wear.

- Plating: Plating adds a thin layer of metal, such as nickel or chrome, to the surface to enhance the product’s appearance and protect it from rust.

Finishing ensures that the final product not only looks good but also performs reliably in its intended environment.

Step 6: Quality Control and Testing

Before shipping the product to customers, manufacturers perform quality control and testing. They check that the product meets all the required specifications and standards. Tools like calipers, micrometers, and laser scanners help measure the product’s dimensions to ensure accuracy.

In addition to measuring, fabricators test the product’s strength, durability, and functionality. By identifying any issues at this stage, they can fix defects before mass production begins, ensuring the highest quality for the final product.

Conclusion

In this article, we have learned about the Sheet metal processing process. Sheet metal processing is a step-by-step process that transforms raw metal into functional products. From design and planning to cutting, bending, assembly, and finishing, each stage plays an important role. Manufacturers focus on accuracy and precision at every step to ensure that the final product meets industry standards. As technology continues to advance, sheet metal processing will only become faster, more efficient, and more reliable for various industries.